Autonomous Maintenance

Smart Autonomous Maintenance for Today’s Modern Factory

Give operators more control over equipment cleaning, inspections, and lubrications to improve CIL completion rate.

Raise Safety, Quality, and Maintenance notifications in the flow of work to reduce the time to correction.

Augmentir’s suite of connected worker tools and closed-loop autonomous maintenance solution helps intelligently guide and support operators, resulting in minimized machine downtime.

Smart Autonomous Maintenance

- Digitize your autonomous maintenance processes to increase standard work adherence, clear defects more quickly, and improve auditability.

- Enable operators to share knowledge and have access to all the information and resources they need to solve problems quickly, reducing unplanned downtime.

- Integrate skills management into the flow of work, empowering line supervisors with real-time endorsements levels so they can assign work with 100% confidence that it will be done safely and correctly.

- AI-based insights help identify workforce development opportunities for upskilling and reskilling, always investing in the right people at the right time.

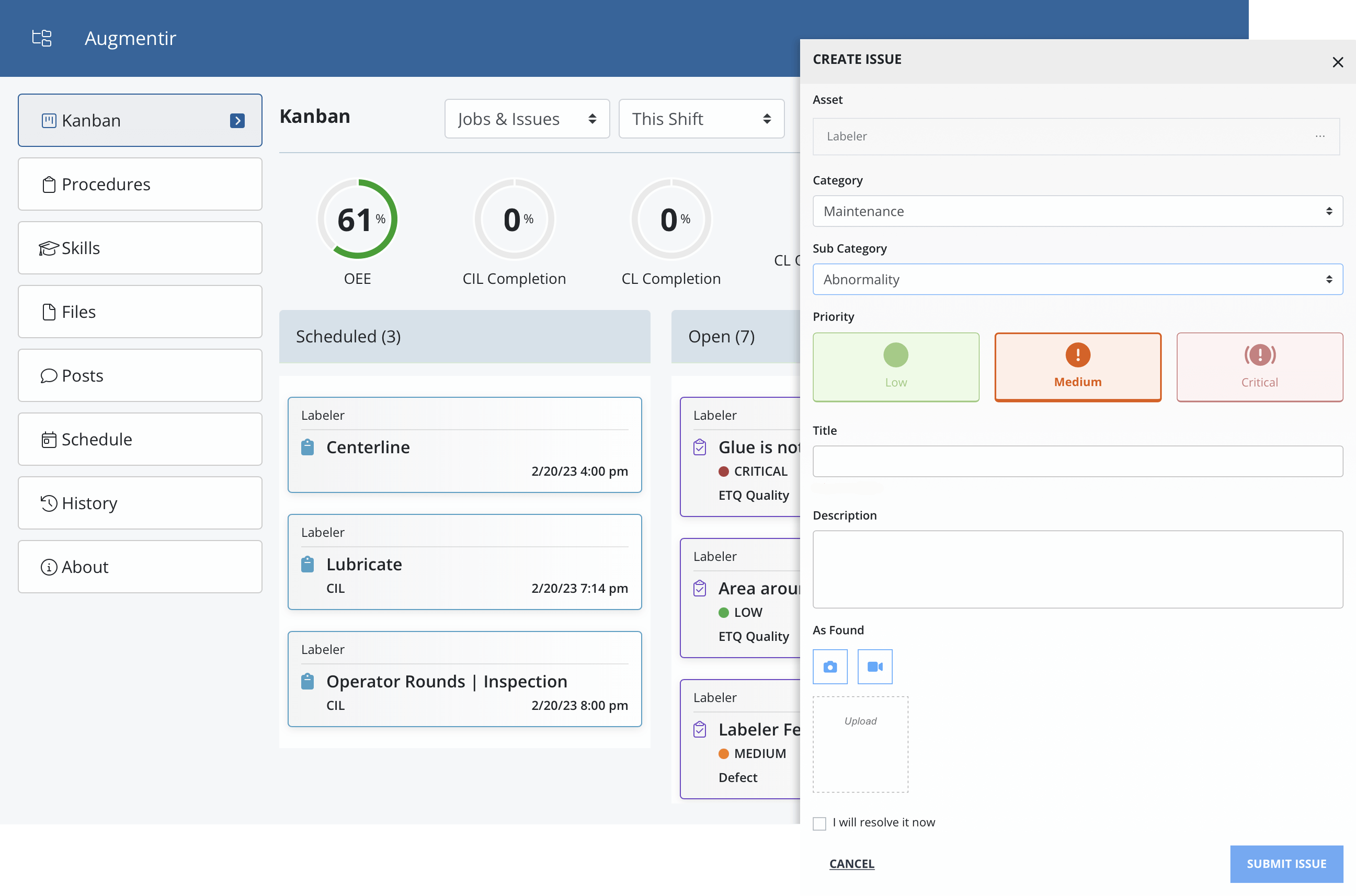

Issue Management

Track and Manage Issues and Activities

Raise safety, quality, and maintenance notifications in the flow of work to reduce the time to correction.

Digitally track and manage maintenance notifications with a visual Kanban board. Escalate maintenance notifications to CMMS.

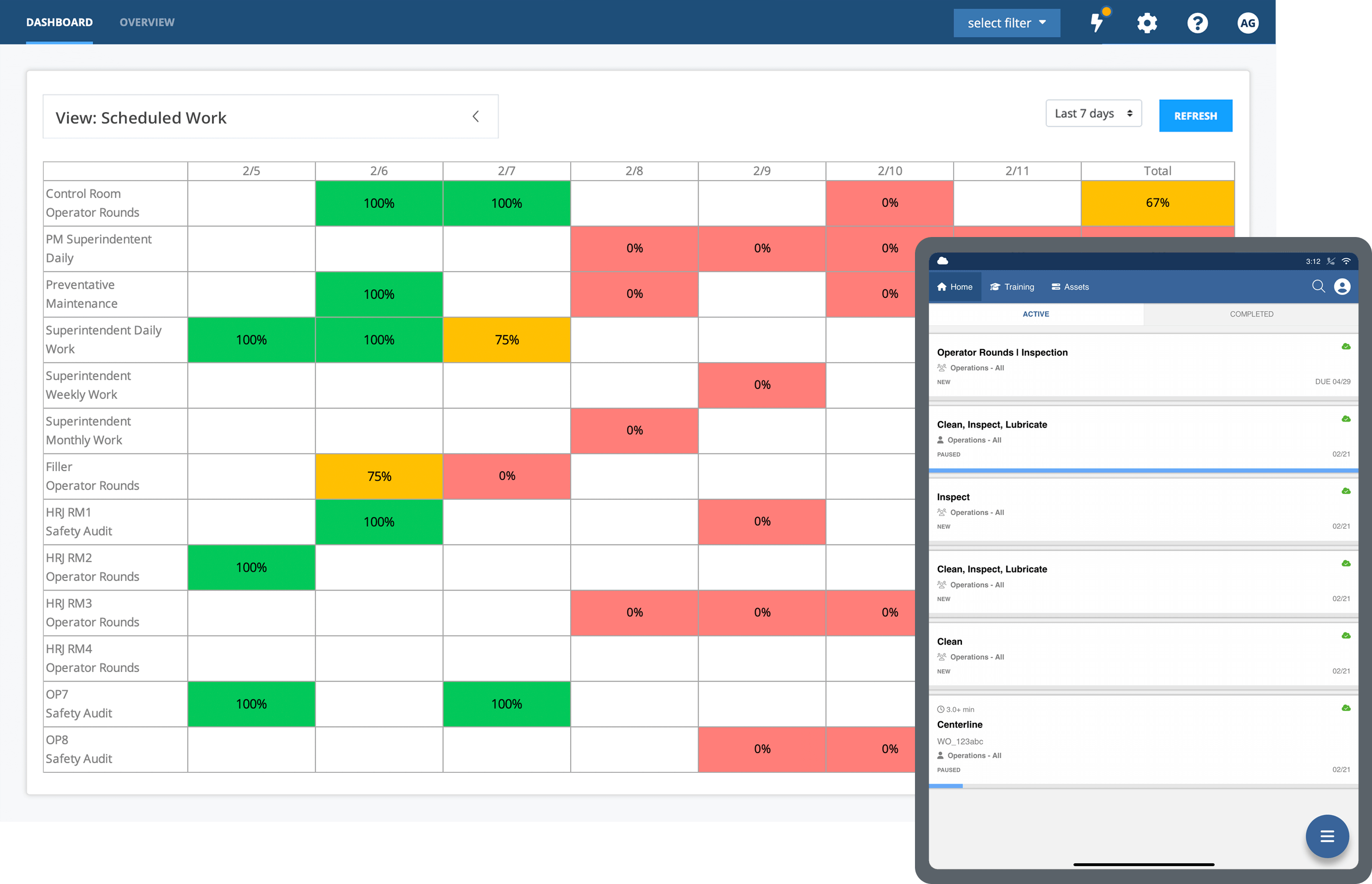

Standard Work

Schedule and Audit Standard Work

Schedule and assign standard work (Operator Rounds, Safety Audits, CILs, Centerlining procedures) and visually audit the work being done with built-in scheduled work reporting.

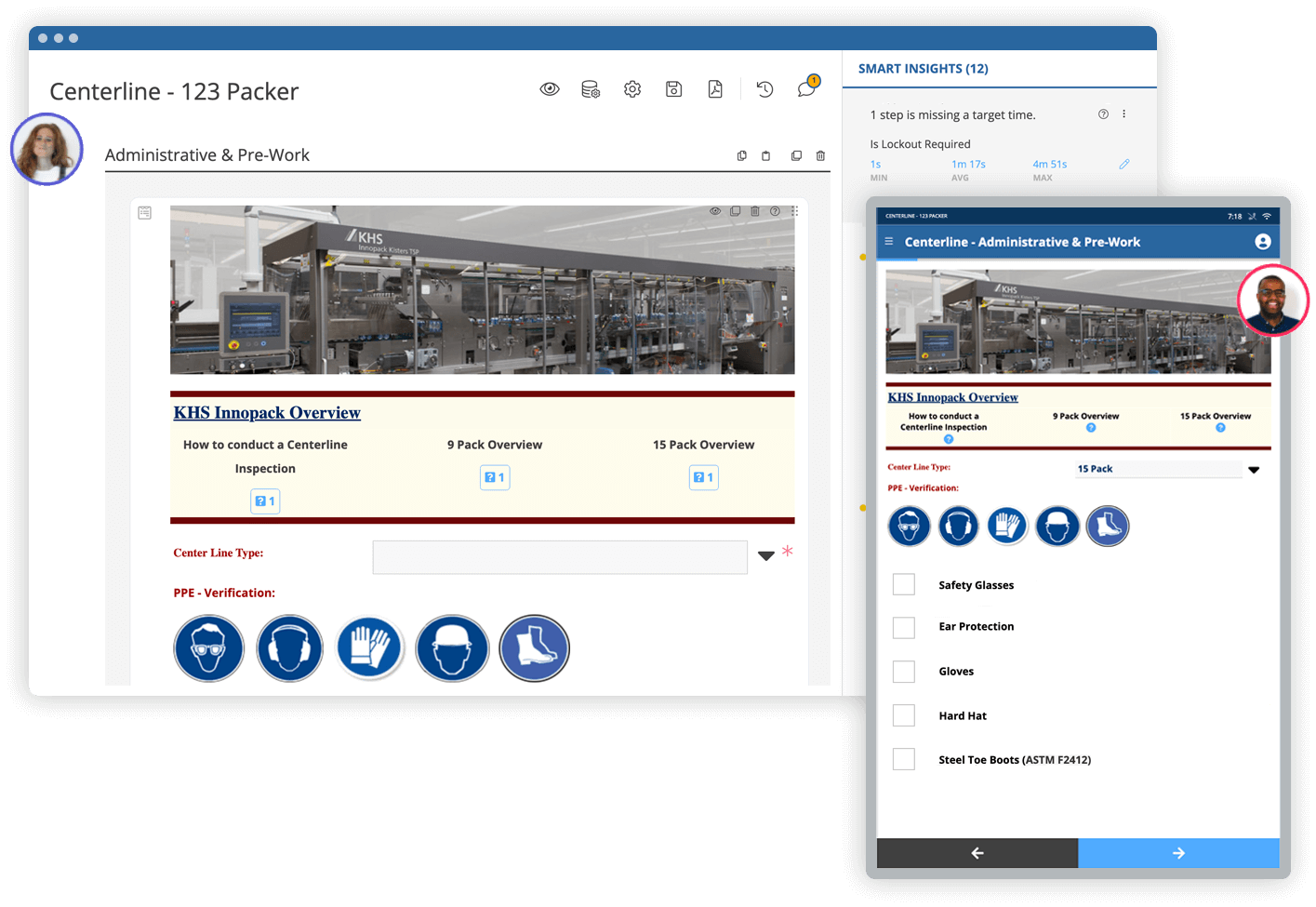

Knowledge Management

Simple Access to Content and Knowledge

Give your workers quick access to the content and knowledge they need to do their job. Augmentir provides a searchable asset hierarchy, maintenance history, and troubleshooting database.

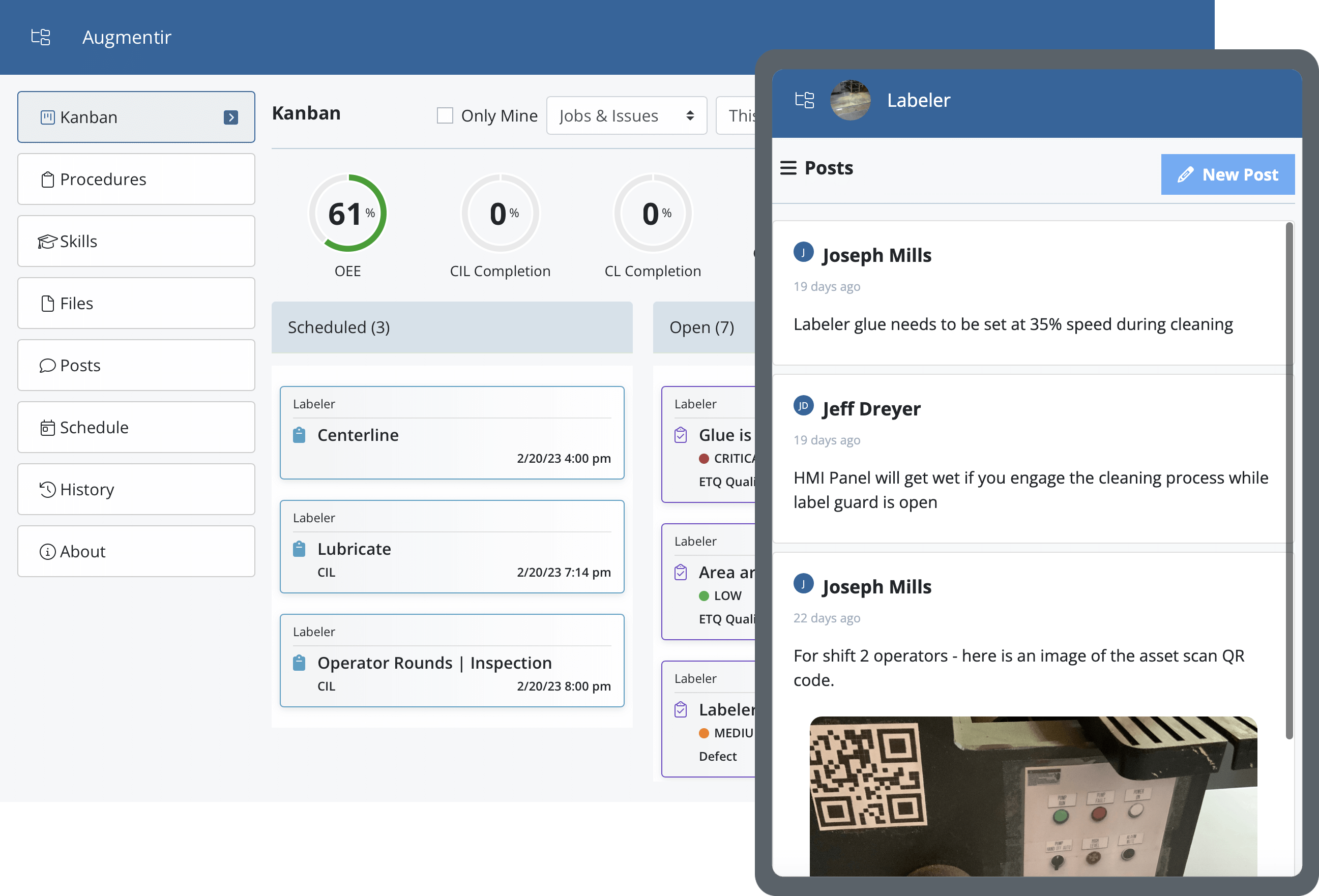

Collaboration

Smart Communication and Collaboration

Effective communication is essential in a factory setting to ensure safety, quality, efficiency, collaboration, and decision-making.

With Augmentir, manufacturers can connect workers across locations and shifts, resulting in improved communication and workforce productivity. Share important news and updates to the production process, and knowledge around production problems, issues, and assets. Enable team collaboration for faster issue resolution. Digital shift handovers streamline communications.

Enterprise Integration

Escalate Maintenance, Safety, and Quality Notifications

Frontline workers often witness quality, safety, or maintenance issues on the factory floor. They are effectively a “human sensor” in the manufacturing process and can readily identify defects or issues that need to be addressed. Today, the manual, paper-based process for resolving issues leads to latency and little-to-no feedback to the frontline worker on resolution.

With Augmentir, these connected workers have a digital connection to enterprise systems of record – QMS, Safety, CMMS, which allows for the autonomous collection of incident data and the ability to speed up time to resolution.

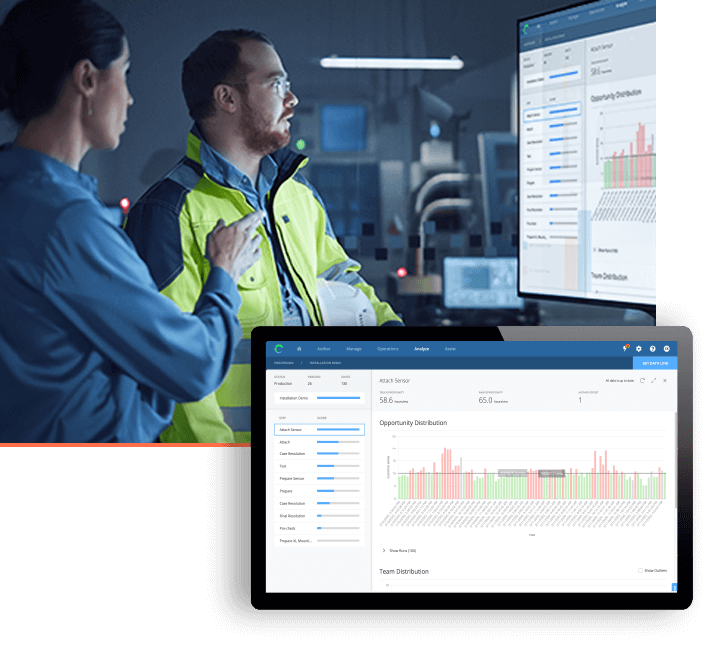

Workforce Intelligence

Workforce Intelligence enables closed loop worker performance support

Augmentir’s Smart AI – automatically identifies your largest workforce improvement opportunities:

True Productivity™ – stack ranks your largest productivity opportunities across all work processes to focus continuous improvement teams at the highest ROI

True Performance™ – determines the proficiency and performance of every worker at every task enabling truly personalized workforce development investments

Who Augmentir Helps

Plant Manager

Improve communication across your operation by digitizing and automating maintenance notifications. Seamlessly build notifications and escalations into digital work instructions for maintenance procedures.

Supervisor

Gain unprecedented insights into worker productivity and competency, allowing for more intelligent scheduling and job assignments.

Quality Control

Improve the quality, transparency, and efficiency of maintenance procedures, regardless of who is performing the maintenance tasks.

Operator

Give operators more control over equipment cleaning, lubricating, and inspection to identify issues early on before they become failures.

Maintenance Tech

Free up dedicated maintenance teams to focus on more complex maintenance tasks that require specialized skills.

Continuous Improvement

Augmentir focuses continuous improvement teams on areas of largest improvement opportunities in workforce productivity and work process improvement.

Resource Library

Want to Learn More?

Explore our library of free resources to get you started on your digital transformation journey. Our collection of eBooks, Webinars, Articles, and Events will give you the insights and best practices you need to succeed.

Workforce Management Tools to the Industrial Frontline Workforce

A new generation of AI-based connected worker tools are allowing companies to deliver effective skills management, training, collaboration, and on the job support for today’s more dynamic, more flexible industrial workforce.

This Is Not Your Grandfather’s Workforce

Today’s dynamic and changing manufacturing workforce needs continuous learning and performance support to effectively sustain and deliver effective on-the-job performance.

Build a Modern, Connected Workforce with AI

Today’s dynamic and changing manufacturing workforce needs personalized guidance and support, as well as continuous learning opportunities in order to effectively sustain and deliver effective on-the-job performance. Learn how AI is being used to shape today’s new workforce and address some of manufacturing’s biggest challenges.