5S Audit

5S Audit Checklist Software

Augmentir’s 5S audit software helps manufacturers digitally capture 5S audit data, allowing them to focus on organizing and optimizing the workplace to reduce waste, increase efficiency, and improve safety.

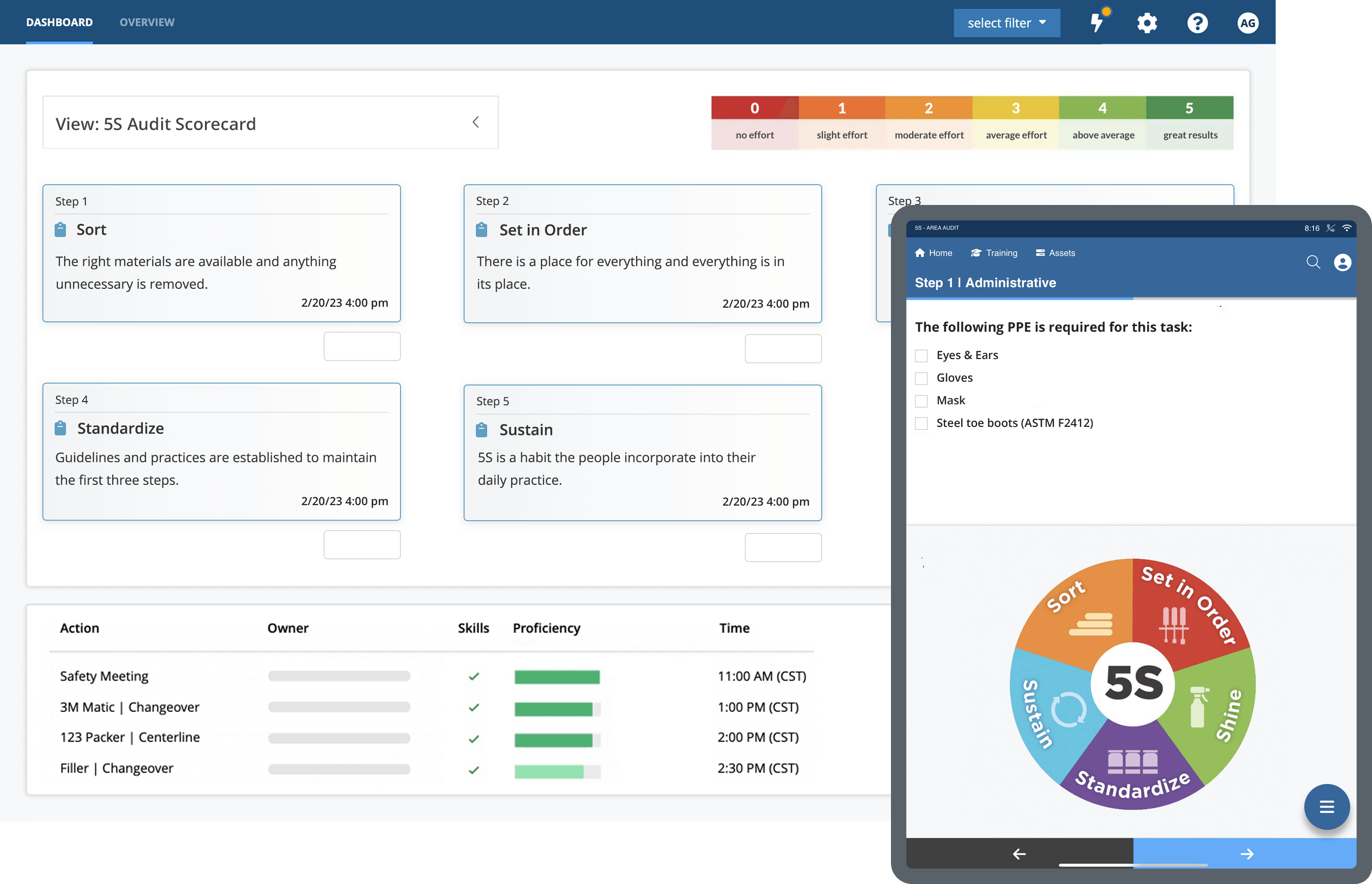

Digitize your 5S Audit checklists with software from Augmentir

Creating digital checklists for 5S audits offers several benefits over traditional paper-based checklists. With Augmentir, manufacturers can quickly create digital checklists and improve the accuracy and reporting of 5S processes. This 5S audit software is built on top of Augmentir’s AI-powered platform, offering a complete suite of out-of-the box connected worker capabilities, including skills management, digital workflows, collaboration, and operational insights.

- Identify areas for improvement: 5S audits help identify areas where improvements are needed in order to increase efficiency, productivity, and safety.

- Encourage employee participation: Conducting a 5S audit encourages employee participation in workplace improvement initiatives, fostering a culture of continuous improvement.

- Improve workplace safety: 5S audits have the potential to identify and eliminate workplace hazards, promoting a safer work environment.

- Reduce waste: 5S focuses on identifying, reducing, and eliminating waste in the workplace, leading to cost savings.

- Improve customer satisfaction: 5S audits promote well-organized and efficient workplaces, that improve customer satisfaction by ensuring timely delivery of products and services.

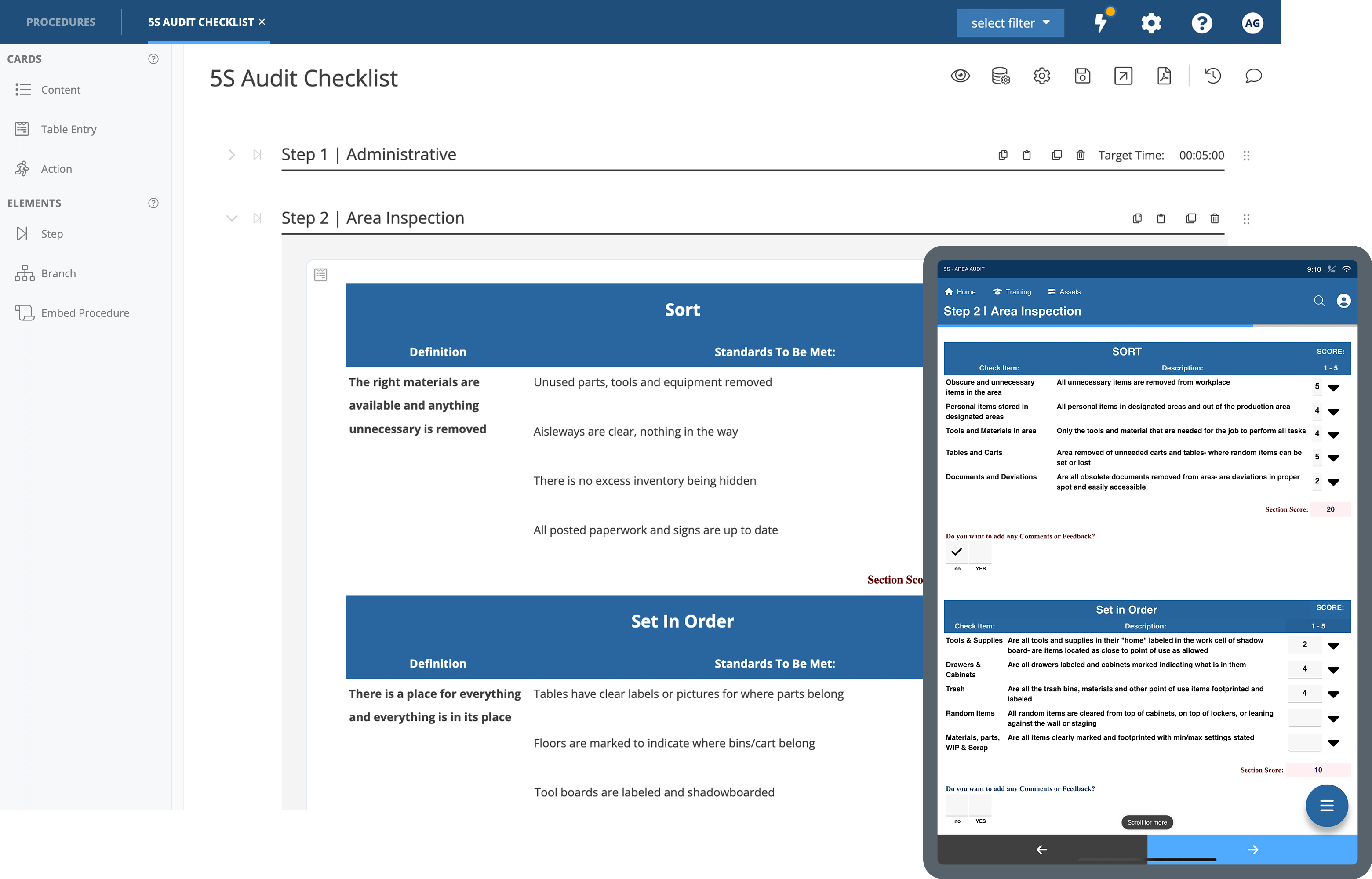

Create Digital Checklists

Digitize your 5S Audit Checklists

Quickly create digital 5S checklists using Augmentir’s pre-configured templates. Augmentir’s content creation and No-Code workflow builder tools help companies configure checklists and data collection processes to meet operational requirements. Intelligently deliver personalized guidance and instruction matched to the needs of each worker.

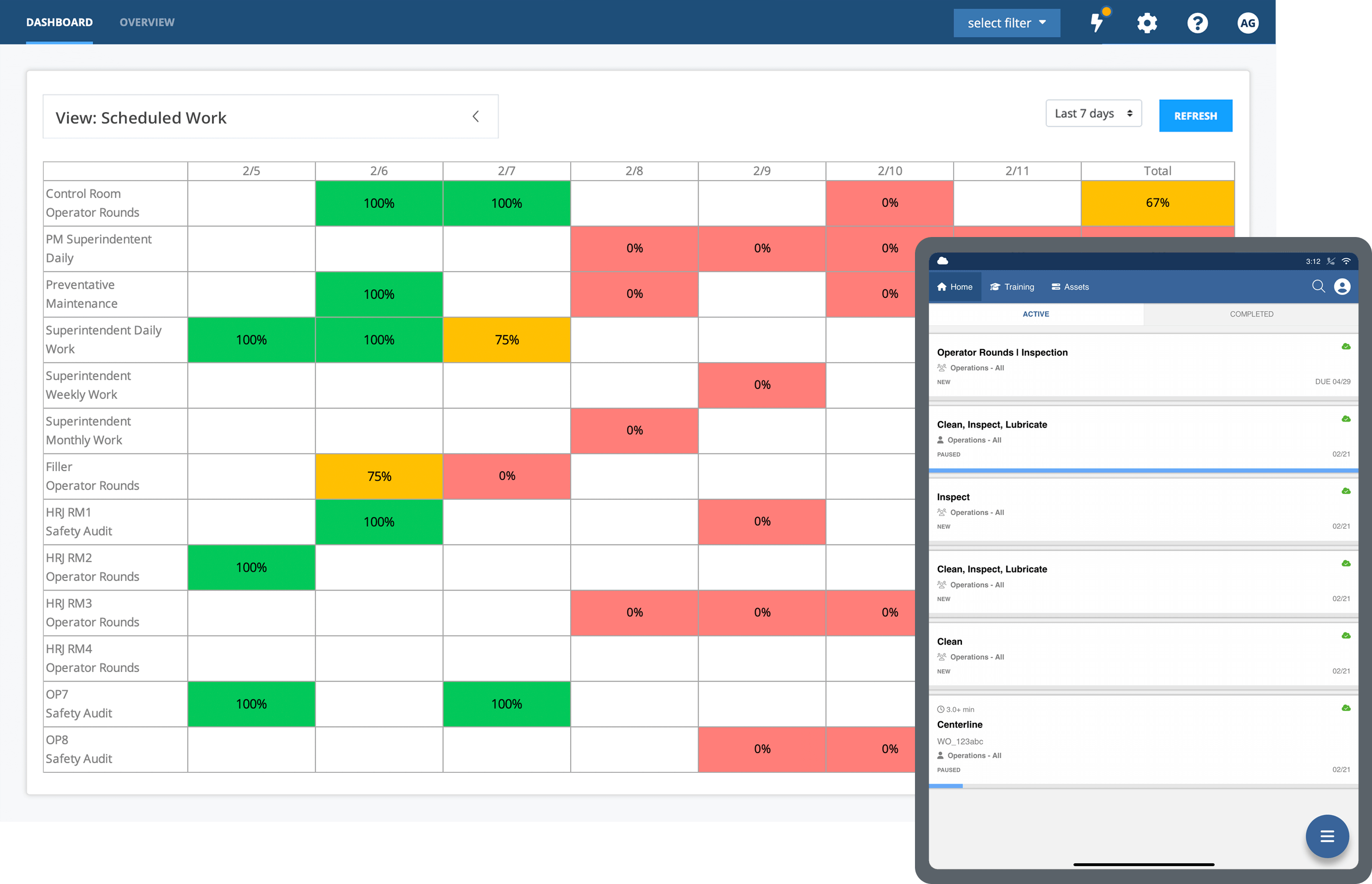

Standard Work

Schedule and Audit Standard Work

Incorporate 5S Audits into your standard work with Augmentir’s built-in scheduling capabilities. Schedule and assign standard work (5S Audits, Operator Rounds, Safety Checks, CILs, Centerlining procedures) and visually manage the work being done with built-in scheduled work reporting.

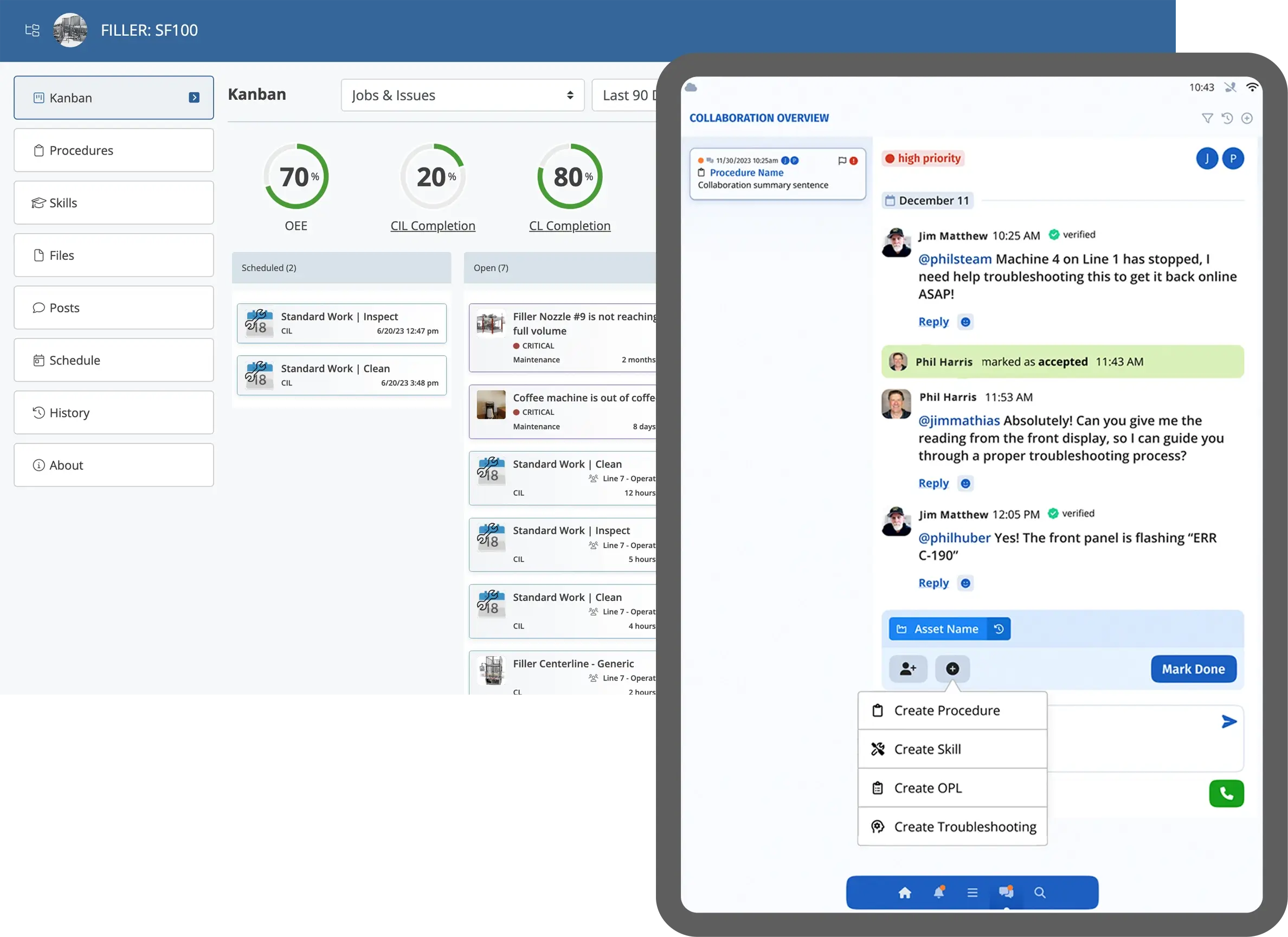

Collaboration

Smart Communication and Collaboration

Effective communication is essential in a factory setting to ensure safety, quality, efficiency, collaboration, and decision-making.

With Augmentir, manufacturers can connect workers across locations and shifts, resulting in improved communication and workforce productivity. Share important news and updates to the production process, and knowledge around production problems, issues, and assets. Enable team collaboration for faster issue resolution. Digital shift handovers streamline communications.

Reporting & Analytics

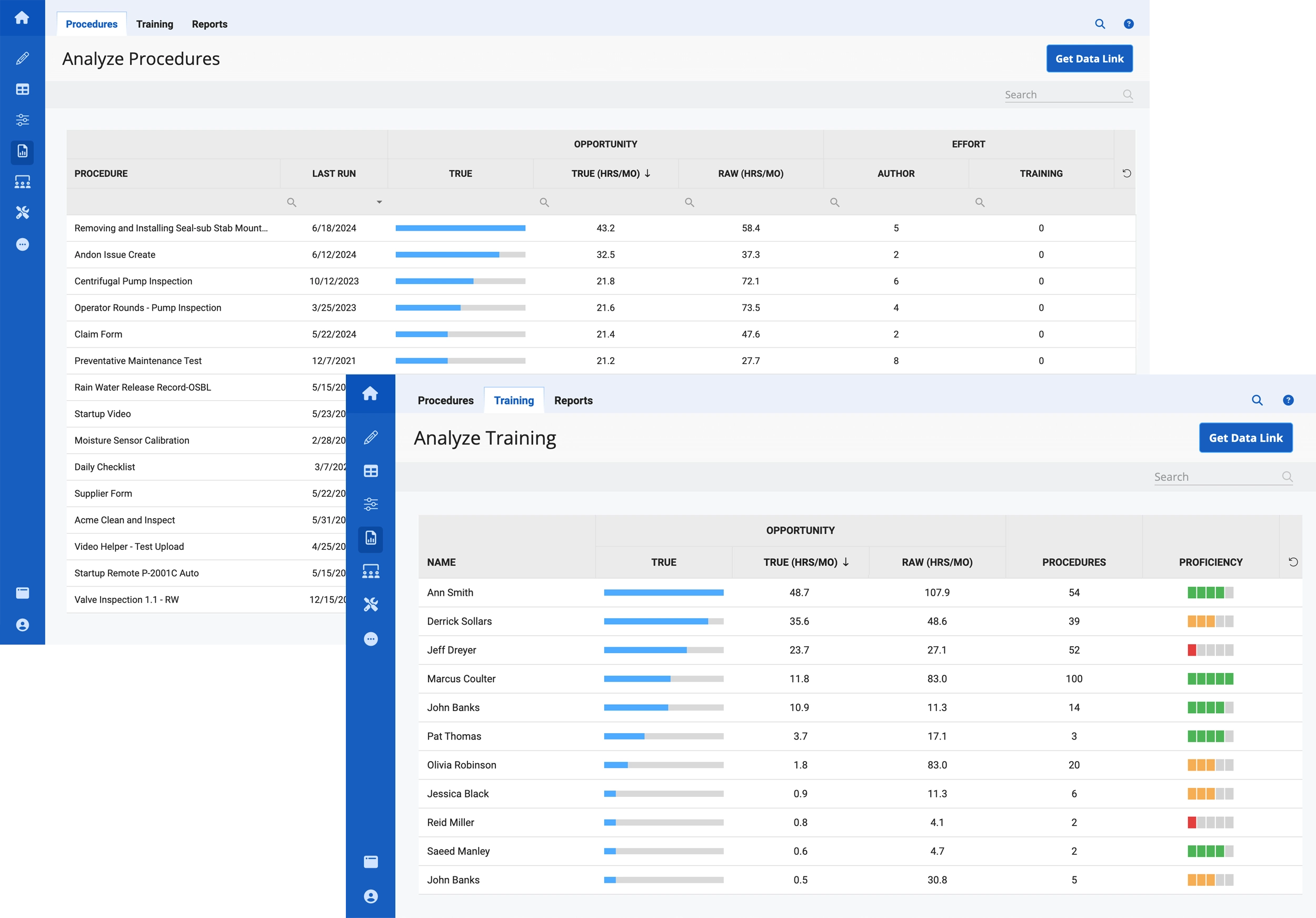

Workforce Intelligence enables closed loop worker performance support

Augmentir’s Smart AI – automatically identifies your largest workforce improvement opportunities:

True Productivity™ – stack ranks your largest productivity opportunities across all work processes to focus continuous improvement teams at the highest ROI

True Performance™ – determines the proficiency and performance of every worker at every task enabling truly personalized workforce development investments

Resource Library

Want to Learn More?

Explore our library of free resources to get you started on your digital transformation journey. Our collection of eBooks, Webinars, Articles, and Events will give you the insights and best practices you need to succeed.

Workforce Management Tools to the Industrial Frontline Workforce

A new generation of AI-based connected worker tools are allowing companies to deliver effective skills management, training, collaboration, and on the job support for today’s more dynamic, more flexible industrial workforce.

This Is Not Your Grandfather’s Workforce

Today’s dynamic and changing manufacturing workforce needs continuous learning and performance support to effectively sustain and deliver effective on-the-job performance.

Build a Modern, Connected Workforce with AI

Today’s dynamic and changing manufacturing workforce needs personalized guidance and support, as well as continuous learning opportunities in order to effectively sustain and deliver effective on-the-job performance. Learn how AI is being used to shape today’s new workforce and address some of manufacturing’s biggest challenges.