Learn how to apply everboarding in manufacturing, and how it is replacing traditional onboarding and training methods.

According to Brandon Hall Group research, investment in employee training and development programs to enhance skills and knowledge is the highest-rated initiative globally to improve the employee experience. One highly effective approach towards revolutionizing training and onboarding is a continuous learning method called everboarding.

Everboarding is a modernized approach toward employee onboarding and training that recognizes learning as a continuous and ongoing process. Its foundational characteristic is the belief that learning doesn’t stop after the initial onboarding period. Instead, everboarding emphasizes continuous skill development and employee knowledge enhancement throughout their careers.

Applying everboarding in a manufacturing environment involves tailoring continuous learning and development approaches to the unique needs and challenges of factory floor operations. As industrial processes evolve, employees must be routinely educated on process improvements, new technologies, safety standards, and efficiency initiatives.

Read on to learn more about how to apply everboarding to the factory floor and how fostering a culture of continuous improvement and learning keeps frontline workers safe, efficient, and engaged:

- Steps for Implementing Everboarding in Manufacturing Operations

- 5 Useful Everboarding Technologies

- Improving Manufacturing Training with Everboarding

Steps for Implementing Everboarding in Manufacturing Operations

Everboarding in the context of the manufacturing industry refers to a forward-looking approach that ensures employees remain well-trained, adaptable, and aligned with industry standards throughout their tenure. This is essential in dynamic and fast-paced industrial environments like manufacturing. Here are some steps and strategies to begin implementing everboarding in your operations:

- Operationalize Learning: Develop and maintain a systematic approach to training and workforce development and ensure that ongoing training and development are available for all shop floor workers.

- Develop Learning Pathways: Create clear learning pathways and career development plans for employees. These pathways should outline the skills and knowledge required for career advancement within the manufacturing shop floor.

- Implement Digital Learning Platforms: Leverage digital learning platforms and smart, connected solutions to provide employees with access to training materials, videos, courses, and other resources. These platforms can track progress, and employees can learn at their own pace.

- Integrate Learning into the Workflow: Using digital, mobile, and connected technologies, organizations can integrate training into the factory floor for moment-of-need guidance and microlearning that allows frontline workers to stay compliant and operations to continue smoothly.

- Provide Feedback and Improvement Loops: Create a feedback mechanism where employees can provide suggestions for improving training programs and processes. Make sure to act on the feedback to continuously enhance the training experience.

- Initiate Regular Skill Assessments: Implement regular assessments and evaluations to identify areas where employees need further training or improvement.

Everboarding in a manufacturing factory floor environment is critical for keeping the workforce skilled, adaptable, and able to meet changing demands and technological advancements. By fostering a culture of continuous learning and improvement, you can ensure that the factory floor remains efficient and productive.

5 Useful Everboarding Technologies

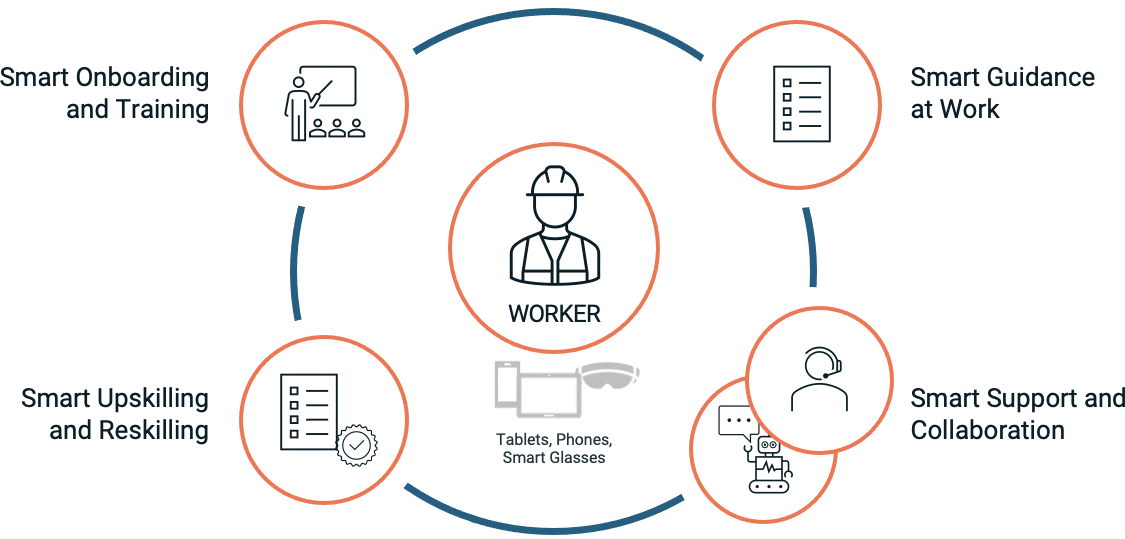

Implementing Everboarding in manufacturing requires the use of various technologies to facilitate continuous learning and skill development. Here are five (5) useful technologies that can help speed the adoption of everboarding methods on the factory floor and support frontline workers on their continuous learning paths.

- Learning Management Systems (LMS): LMS platforms are essential for delivering and managing training content. They allow manufacturing companies to organize courses, track employee progress, and ensure compliance with training requirements.

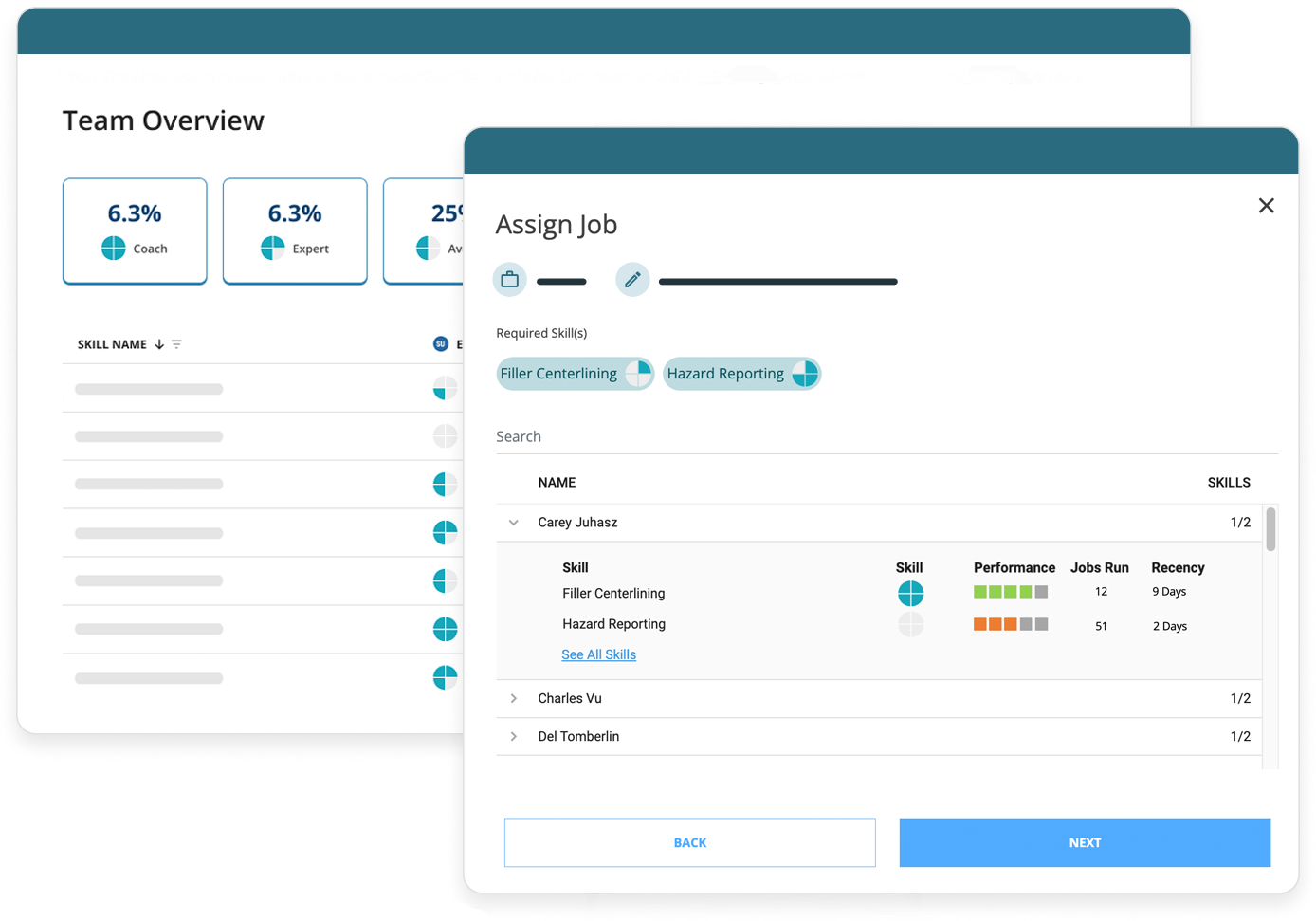

- Connected Worker Applications: Connected worker applications provide mobile solutions, real-time data, and actionable insights that enable customized and personalized training dedicated to the needs of individual workers and specific tasks.

- Artificial Intelligence (AI): AI-driven systems can personalize training content based on employee performance and preferences. AI’s ability to process vast amounts of data, provide personalized experiences, and offer real-time feedback makes it a powerful tool for implementing everboarding.

- Internet of Things (IoT): IoT sensors can be integrated into manufacturing equipment to gather data on machine performance and employee interactions. This data can inform training needs and help identify areas for improvement.

- Wearable Technology: Wearable devices can be used for on-the-job training and performance monitoring. They are especially useful in high-risk manufacturing environments.

These technologies leverage connectivity, digital tools, and data to create a more dynamic and adaptive learning environment for frontline employees. By integrating emerging technologies like smart, connected worker solutions into manufacturing operations, companies can create a more agile and adaptive learning environment that supports the foundations of everboarding.

Digital training tools can help implement everboarding and improve learning speed and retention. For example, workers who need visuals or real-world scenarios can access them using AI-powered software to create a comprehensive everboarding and training program that supports frontline employees throughout the entire skills and training lifecycle.

Improving Manufacturing Training with Everboarding

Implementing new learning technologies in any industry is met with a certain number of challenges. This remains especially true for the factory floor where training and development are traditionally separate from the work being done, and where traditional onboarding has been a one-and-done type of approach.

However, because everboarding is a process of continuous learning, organizations can improve their industrial training and onboarding, ensuring employees continually acquire new skills and knowledge to adapt to evolving technologies and processes. This not only helps in training new employees but also enables continuous learning and skill development for the entire workforce, improving productivity, safety, and quality in the process.

Implementing everboarding in factory floor operations can seem complex but it is a rewarding process that can be streamlined through solutions like Augmentir’s connected worker solution. With our AI-driven insights, our connected solution reduces onboarding time and transforms workforce training, bringing learning to the factory floor through intelligent guidance that delivers information to workers at the point of need.

Learn how manufacturers are implementing Augmentir’s AI-driven connected worker tools to capture and digitize tribal knowledge, reskill and upskill their workers, and empower their frontline teams – schedule a live demo today.