Learn how manufacturers combat the manufacturing skilled labor shortage and close skills gaps with an Augmented Connected Workforce (ACWF).

Generative AI in manufacturing refers to the application of generative models and artificial intelligence techniques to optimize and enhance various aspects of the manufacturing process. This involves using AI algorithms to generate new product designs, optimize production workflows, predict maintenance needs, and improve production efficiency within frontline operations.

According to McKinsey, nearly 75% of generative AI’s major value lies in use cases across four areas: manufacturing, customer operations, marketing and sales, and supply chain management. Manufacturers are uniquely situated to benefit from generative AI and it is already a transformative force for some. A recent Deloitte study found that 79% of organizations expect generative AI to transform their operations within three years, and 56% of them are already using generative AI solutions to improve efficiency and productivity.

Manufacturing is rapidly evolving and by integrating cutting-edge technologies like Generative AI, manufacturers can better support, augment, and enhance their frontline workforces with improved decision-making, collaboration, and data insights.

Join us below as we dive into generative AI in manufacturing exploring how it works, the benefits and risks, and some of the top use cases that generative AI, specifically generative ai digital assistants, can provide for manufacturing operations:

- What is Generative AI in Manufacturing

- Benefits of Leveraging Generative AI in the Manufacturing Industry

- Risks of Generative AI in Manufacturing

- Top Use Cases of Generative AI Manufacturing Assistants

- Future-proofing Manufacturing Operations with Augie™

What is Generative AI in Manufacturing

Generative AI refers to artificial intelligence systems designed to create new content, such as text, images, or music, by learning patterns from existing data. In manufacturing, this involves the use of Large Language Models (LLMs) and Natural Language Processing (NLP) to analyze vast amounts of data, simulate different scenarios, and generate innovative solutions that can impact a wide range of manufacturing processes.

Large Language Models

Large Language Models (LLMs) are a type of generative artificial intelligence model that have been trained on a large volume – sometimes referred to as a corpus – of text data. They are capable of understanding and generating human-like text and have been used in a wide range of applications, including natural language processing, machine translation, and text generation.

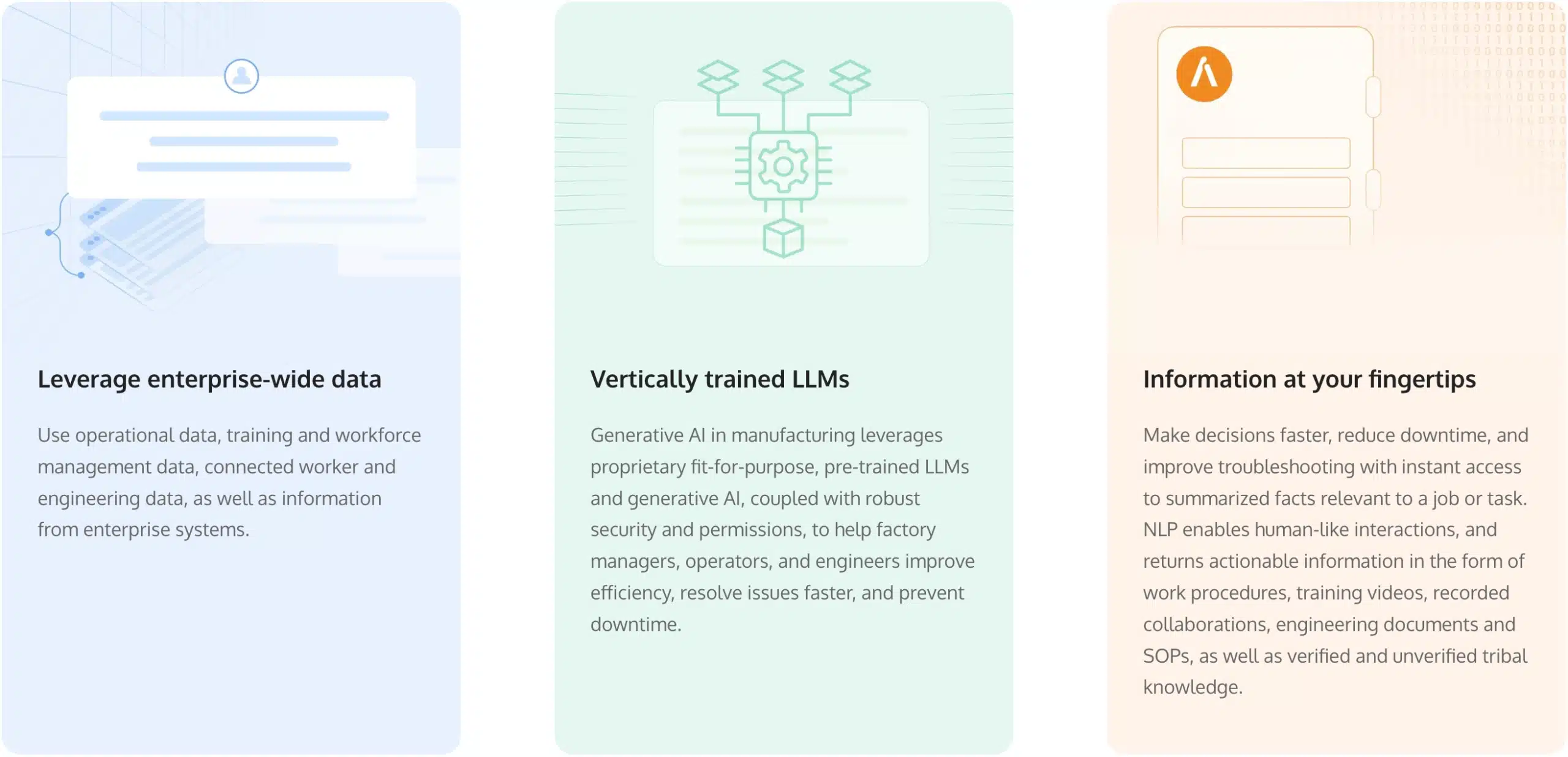

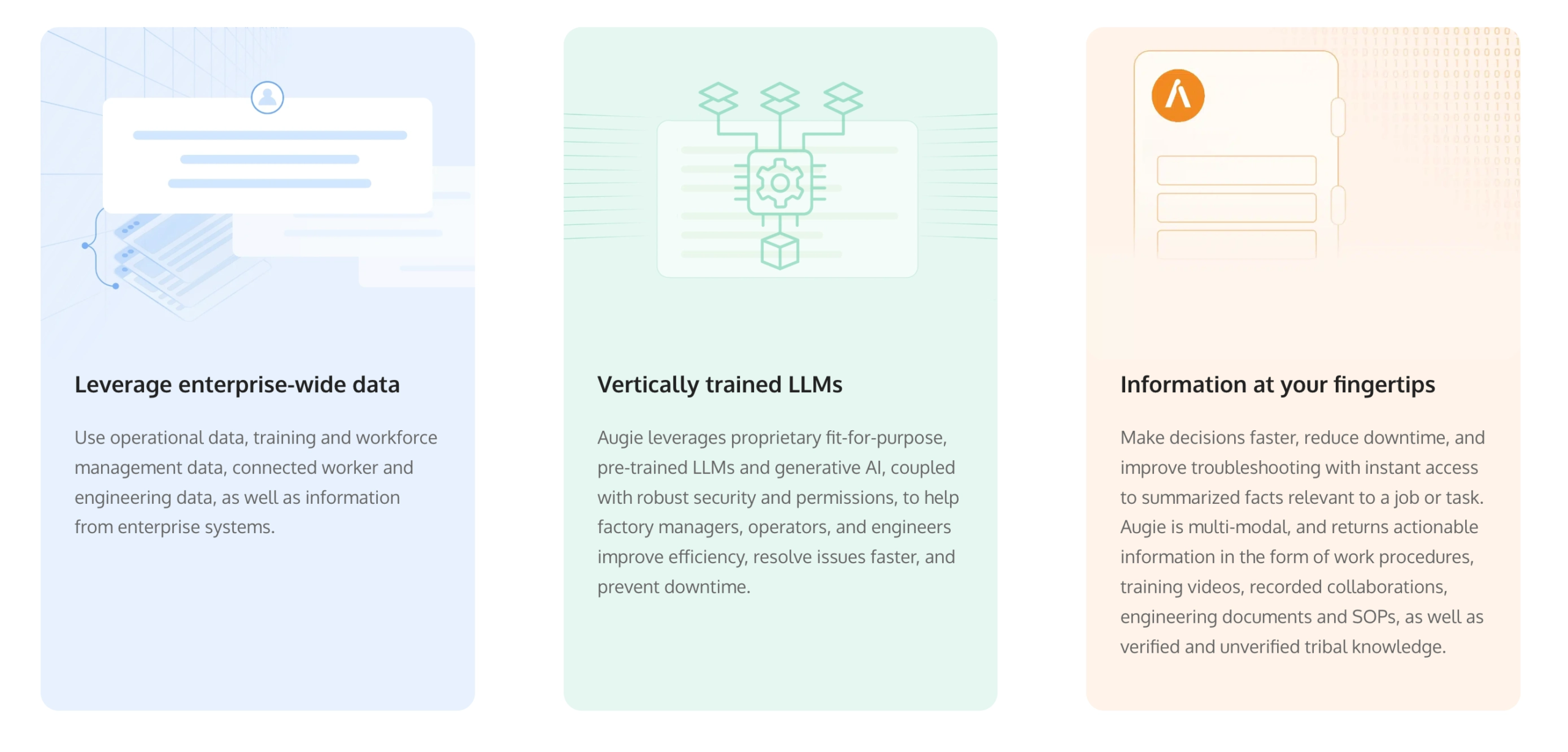

In manufacturing, generative AI solutions should leverage proprietary fit-for-purpose, pre-trained LLMs, coupled with robust security and permissions. Industrial LLMs use operational data, training and workforce management data, connected worker and engineering data, as well as information from enterprise systems.

Natural Language Processing

Natural Language Processing (NLP) is a branch of artificial intelligence that focuses on the interaction between computers and humans using natural language. It involves the development of algorithms and models that enable computers to understand, interpret, and respond to human language in a way that is both meaningful and useful.

For generative AI, NLP is a key technology that enables the assistants to understand and generate human-like text, providing seamless conversational user experiences and valuable assistance to frontline workers, engineers, and managers in manufacturing and industrial settings.

NLPs allow the AI to process and interpret natural language inputs, enabling it to engage in human-like interactions, understand user queries, and provide relevant and accurate responses. This is essential for common manufacturing tasks such as real-time assistance, documentation review, predictive maintenance, and quality control.

By combining large language models and natural language processing, generative AI can produce coherent and contextually relevant text for tasks like writing, summarization, translation, and conversation, mimicking human language proficiency.

Benefits of Leveraging Generative AI in the Manufacturing Industry

Generative AI and solutions that leverage them offer several benefits for manufacturing operations, including:

- Operational/Production Optimization and Forecasting: GenAI technology offers a significant boost to manufacturing processes by monitoring and analyzing in real-time, spotting problems quickly, and providing predictive insights and personalized assistance to boost efficiency for manufacturing workers. Additionally, AI assistants empower manufacturers to explore multiple control strategies within their process, identifying potential bottlenecks and failure points.

- Proactive Problem-Solving: Generative AI-powered tools provide real-time monitoring and risk analysis of manufacturing operations, enabling the quick identification and resolution of issues to optimize production and efficiency. They can spot events as they happen, providing valuable insights and recommendations to help operators and engineers rapidly identify and resolve problems before they escalate.

- Reduce Unplanned Downtime: Generative AI solutions can analyze vast datasets to predict equipment maintenance needs before issues arise, allowing manufacturers to schedule maintenance proactively, minimizing unplanned disruptions. This not only improves downtime but also contributes to the overall operational resilience of mission-critical equipment.

- Personalized Support and On-the-job Guidance: Generative AI tools can be tailored to diverse roles within the manufacturing plant, offering personalized assistance to operators, engineers, and managers. It can provide role-based, personalized assistance, and proactive insights to understand past events, current statuses, and potential future happenings, enabling workers to perform their tasks more effectively and make better, more informed decisions.

These benefits demonstrate the significant impact of generative AI on frontline manufacturing activities, improving overall operational efficiency, adjusting processes where needed, and driving operational excellence.

Generative AI assistants can take these benefits one step further by incorporating skills and training data to measure training effectiveness, identify skills gaps, and suggest solutions to prevent any skilled labor issues. This guarantees that frontline workers have the essential skills to perform tasks safely and efficiently, while also establishing personalized career development paths for manufacturing employees that continuously enhance their knowledge and abilities.

Risks of Generative AI in Manufacturing

Generative AI in manufacturing presents several risks, including data security, intellectual property concerns, and potential bias in AI models. The reliance on vast amounts of data raises the risk of data breaches and cyberattacks, potentially exposing sensitive information. Intellectual property issues may arise if AI-generated designs or processes inadvertently infringe on existing patents or proprietary technologies. Additionally, biases in training data can lead to suboptimal or unfair outcomes, affecting the quality and equity of AI-driven decisions. There is also the risk of over-reliance on AI, which may reduce human oversight and lead to errors if the AI models make incorrect predictions or generate flawed designs. Ensuring proper validation, transparency, and human intervention is crucial to mitigating these risks.

Top Use Cases for Generative AI Manufacturing Assistants

Generative AI assistants and frontline copilots are AI-powered tools designed to provide valuable assistance and insights in industrial settings, particularly in manufacturing. These assistants are a type of generative AI that are used in manufacturing operations to enhance human-machine collaboration, streamline workflows, and offer proactive insights to optimize performance and productivity for frontline workers.

What makes frontline AI assistants unique among other generative AI copilots is the enhanced human-like interaction beyond standard data analytics and analysis to understand the context around a process or issue; including what happened and why, as well as anticipate future events.

Generative AI assistants work via specialized large language models (LLMs) and generative AI, providing contextual intelligence for superior operations, productivity, and uptime in industrial settings. Additionally, they typically involve natural language processing for understanding human language, pattern recognition to identify trends or behaviors, and decision-making algorithms to offer real-time assistance. This, combined with machine learning techniques, allows them to understand user inputs, provide informed suggestions, and automate tasks.

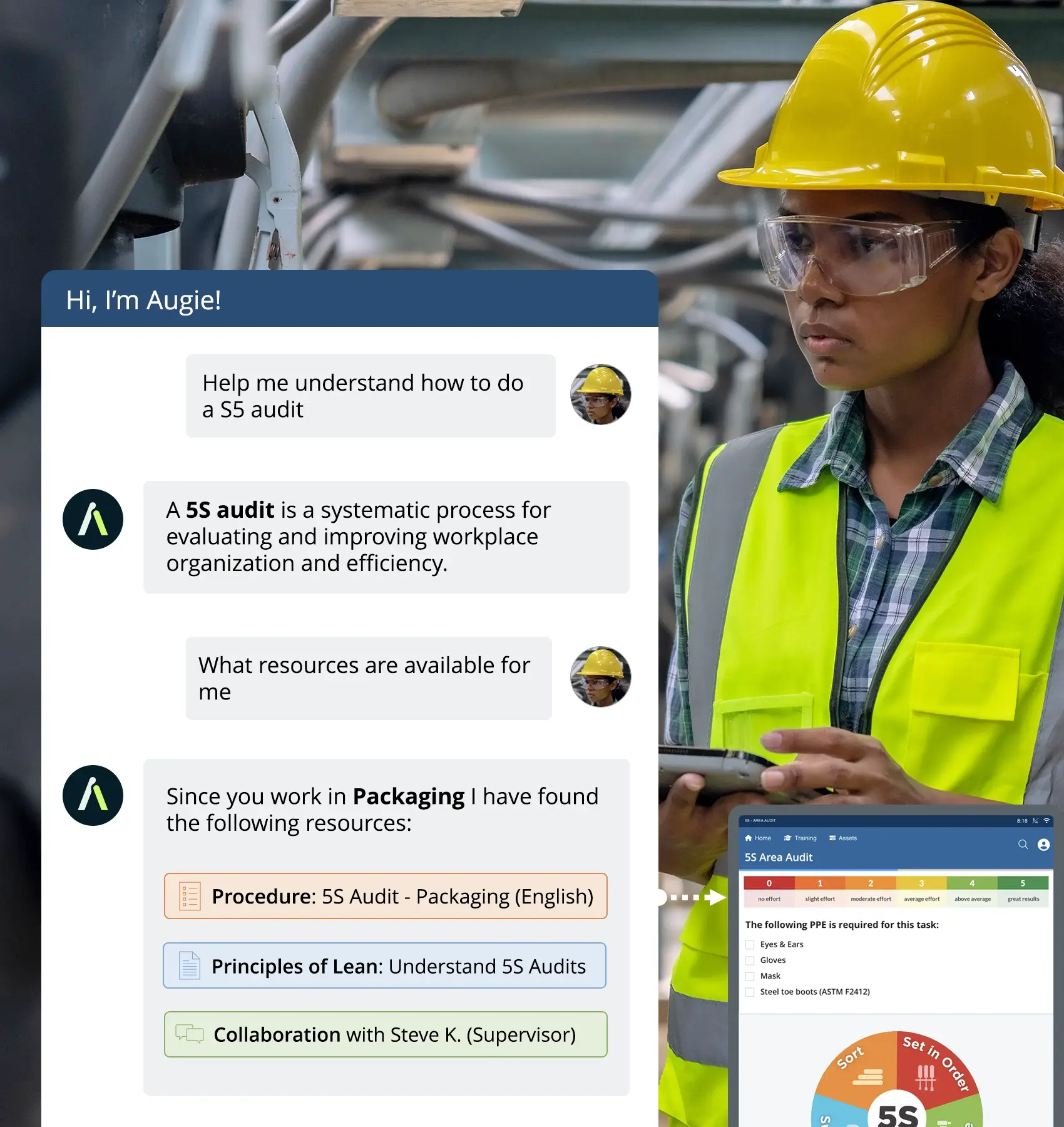

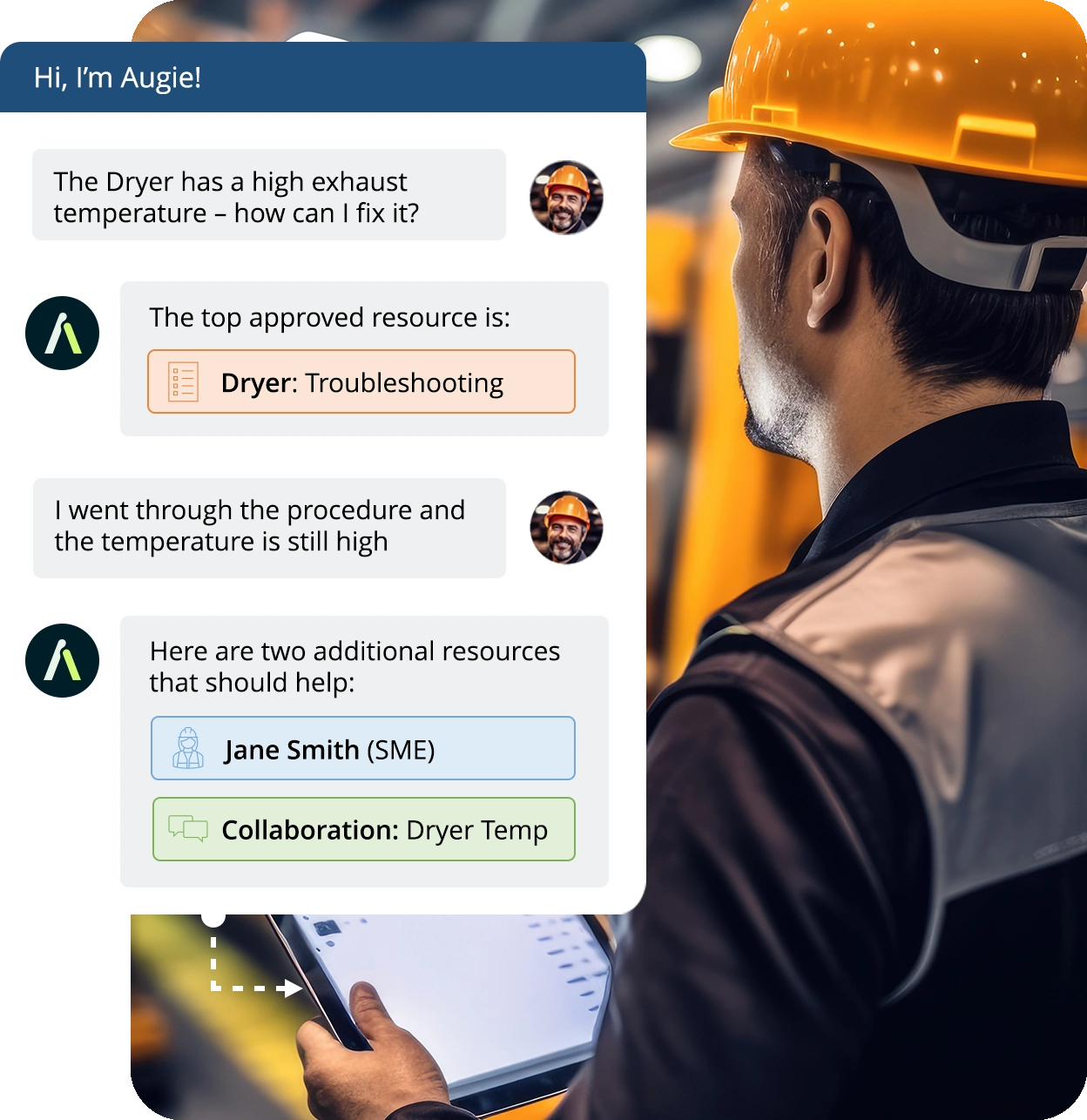

- Troubleshooting:Troubleshooting is such a critical use case in manufacturing. With today’s skilled labor shortage, frontline workers are often times in situations where they don’t have the decades of tribal knowledge required to quickly troubleshoot and resolve issues on the shop floor. AI assistants can help these workers make decisions faster and reduce production downtime by providing instant access to summarized facts relevant to a job or tasks, this could come from procedures, troubleshooting guides, captured tribal knowledge, or OEM manuals.

- Personalized Training & Support: With GenAI assistants, manufacturers can instantly close skills and experience gaps with information personalized, context-aware to the individual worker. This could include: on the job training materials, one point lessons (OPLs), or peer/user generated content such as comments and conversations.

- Leader Standard Work: With Generative AI assistants, operations leaders can assess and understand the effectiveness of standard work within their manufacturing environment, and identify where there are areas of risk or opportunities for improvement.

- Converting Tribal Knowledge: One of the more pressing priorities that many manufacturers face is the task of capturing and converting tribal knowledge into digital corporate assets that can be shared across the organization. With connected worker technology that utilizes Generative AI, manufacturing companies can now summarize the exchange of tribal knowledge via collaboration and convert these to scalable, curated digital assets that can be shared instantly across your organization.

- Continuous Improvement: AI and GenAI assistants can help us identify areas for content improvement, and make those improvements, measure training effectiveness, and measure and improve workforce effectiveness.

- Operational Analysis: Generative AI assistants can also provide value when it comes to operational improvements. GenAI assistants can use employee attendance data to help shift managers or line leaders determine where the risks are, and potentially offset any resource issues before they become truly problematic. An organization’s skills matrix, presence data, and production schedules all can feed into a fit-for-purpose, pre-trained LLM – giving you information that manufacturing leaders need to keep their operations running.

Future-proofing Manufacturing Operations with Augie™

Generative AI and other AI-powered solutions are leveling up manufacturing operations, analyzing data to predict equipment maintenance needs before issues arise, allowing for proactive maintenance scheduling, and minimizing unplanned disruptions. With these tools manufacturers can empower frontline workers with improved collaboration and provide real-time assistance with contextual information, ensuring relevant and timely support during critical decision-making processes.

Overall, generative AI is transforming a wide array of manufacturing and industrial activities, connecting workers in ways that were previously thought impossible, and making frontline tasks and processes safer and more efficient for workers everywhere.

Augie, Augmentir’s new generative AI assistant for frontline work pulls in skill capabilities, workforce development information, and training data in addition to MES and ERP data. It offers contextual, proactive insights and automated workflows to optimize production and prevent bottlenecks, contributing to manufacturing efficiency, uptime, quality, and decision-making.

Additionally, Augie ties together operational data, training and workforce management data, engineering data, and knowledge/information from various disparate enterprise systems to empower frontline workers, streamline workflows, and increase manufacturing performance.

Augmentir is trusted by manufacturing leaders as a digital transformation partner delivering measurable results across operations. Schedule a live demo today to learn more.