Learn how to improve manufacturing shift handover with our downloadable template and AI-powered connected worker solution.

The manufacturing world is at an exciting yet challenging crossroads. Deloitte’s 2025 Manufacturing Industry Outlook paints a vivid picture of the road ahead—one filled with hurdles like labor shortages and rising input costs but also brimming with opportunities driven by digital transformation and innovation. At Augmentir, we see this journey every day through our work with industry leaders, and we’re thrilled to share how our AI platform is helping manufacturers navigate these challenges with confidence and creativity.

Deloitte’s report doesn’t just forecast trends; it highlights the critical role technology plays in shaping the future. For us at Augmentir, this is more than just a validation of our work. It’s a call to action—an affirmation that we’re on the right path to empowering manufacturers with AI to build smarter, more resilient operations. Let’s dive deeper into how Augmentir’s AI platform, and specifically Augie, our Industrial Generative AI Suite, aligns with Deloitte’s vision and how we’re enabling our partners to seize the opportunities ahead.

Tackling Labor Shortages and Value Chain Disruptions

Labor shortages are no longer hypothetical scenarios or statistical warnings—they’re the daily reality for manufacturers. Deloitte’s report underscores the urgency of addressing these workforce challenges, and at Augmentir, we’re ready to help.

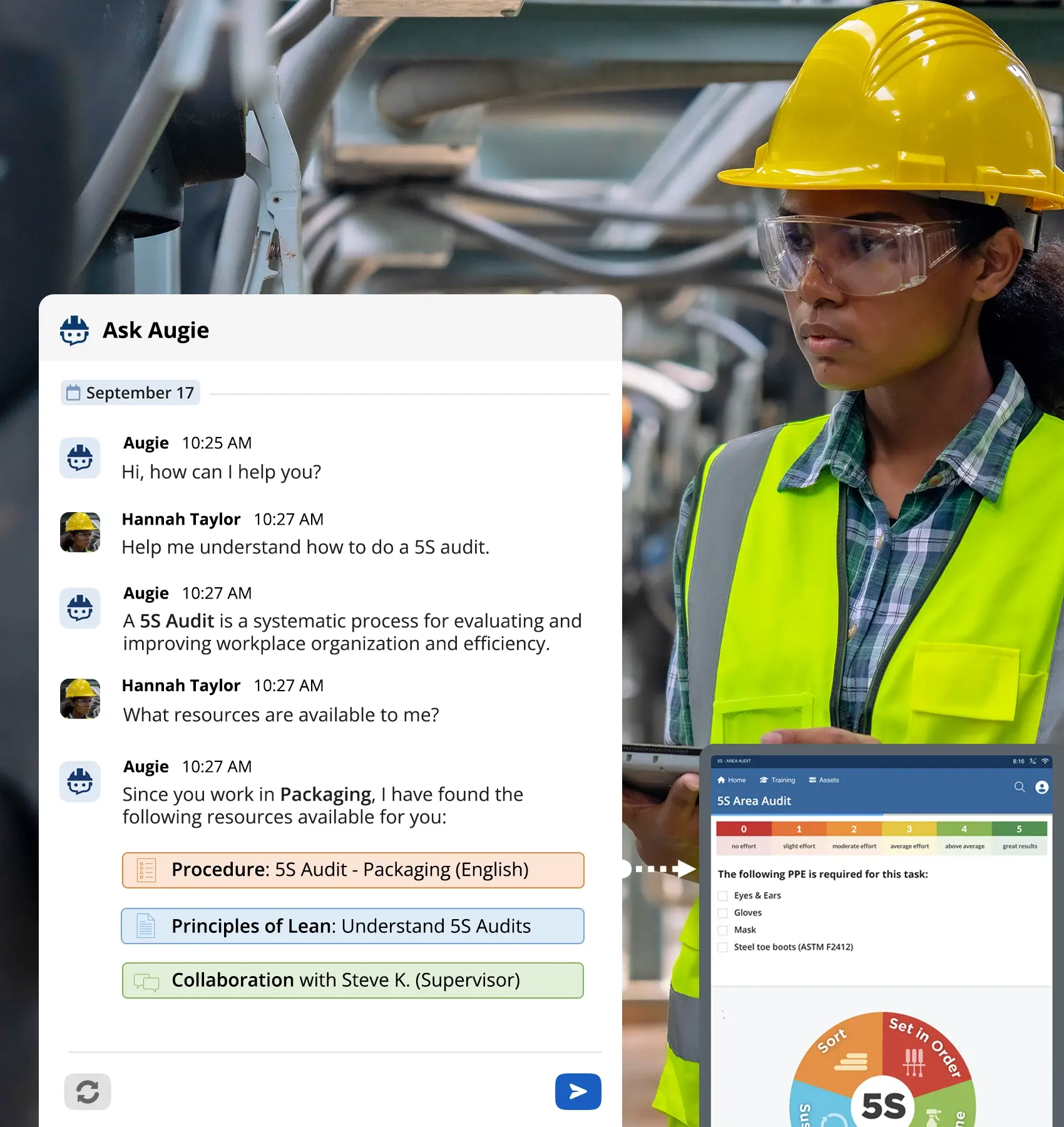

Our industrial Gen AI assistant, Augie, goes beyond just numbers. Yes, it forecasts workforce needs and optimizes staffing levels, ensuring that resources are allocated precisely where they’re needed. But it also does something more profound: it prioritizes people. By streamlining talent management and offering actionable workforce planning insights, Augie helps manufacturers foster environments where employees feel valued and empowered. A happy and engaged workforce is the backbone of any successful operation, and that’s why our solutions are designed to enhance satisfaction and retention alongside productivity.

Supply chain disruptions, another thorn in the industry’s side, are no match for Augie’s analytical prowess. By delivering real-time insights and actionable recommendations, Augmentir helps manufacturers proactively address potential bottlenecks and ensure operational resilience. With Augie, labor and value chain challenges transform from overwhelming obstacles into manageable opportunities.

Managing Rising Input Costs and Enhancing Efficiency

The pressure of rising costs—whether from raw materials or wages—is a constant battle for manufacturers. Every dollar saved can make a monumental difference, but achieving savings without sacrificing quality is a delicate balance. That’s where Augie excels.

Imagine having a personal advisor who’s always on the lookout for ways to optimize your operations. That’s Augie. By analyzing market trends and production data, Augie offers insights into cost-saving opportunities and ways to enhance efficiency. These aren’t generic, one-size-fits-all solutions—they’re tailored recommendations that align with your specific goals.

From optimizing supply chains to fine-tuning production processes, Augie empowers manufacturers to navigate the complexities of rising costs while staying competitive. The result? Greater operational efficiency, better resource allocation, and a clear pathway to long-term sustainability. In today’s fast-paced market, those aren’t just advantages; they’re necessities.

Embracing Smart Operations Through Digital Transformation

The future of manufacturing is undeniably digital, and Deloitte’s report emphasizes the transformative potential of technologies like AI and cloud computing. At Augmentir, we’re not just advocates for digital transformation—we’re enablers.

Augie seamlessly integrates with cutting-edge technologies, enabling manufacturers to unlock the full potential of smart operations. By embracing tools like generative AI and IoT, manufacturers can improve efficiency, foster innovation, and gain a competitive edge. But digital transformation isn’t just about adopting new tools; it’s about rethinking processes and strategies to drive meaningful change. That’s where Augie shines—bridging the gap between traditional manufacturing and the smart factories of tomorrow.

When manufacturers adopt a digital-first mindset, they’re not just investing in technology—they’re investing in growth, resilience, and innovation. And with Augie by their side, that transformation becomes not just achievable but inevitable.

Driving Strategic Innovation and Investment

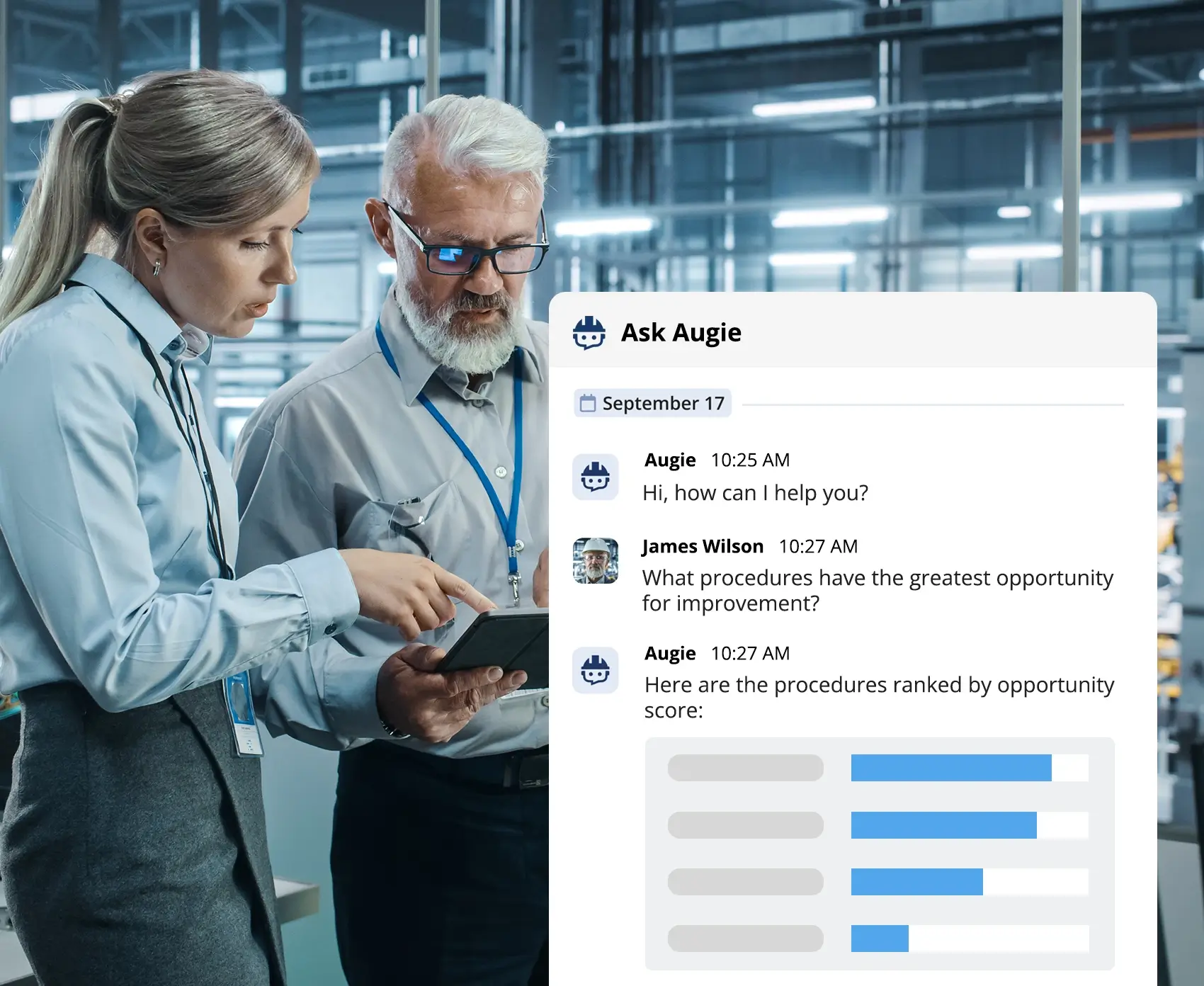

Innovation is the lifeblood of manufacturing, but with countless technologies vying for attention, choosing the right investments can feel overwhelming. Augie simplifies this process by offering data-driven insights into the areas with the highest potential return.

Whether it’s advanced AI, extended reality, or cutting-edge simulation tools, Augie helps manufacturers make informed decisions that align with their strategic goals. From optimizing production lines to enhancing workforce training, Augie ensures that technology investments deliver tangible, meaningful results.

This isn’t just about staying ahead of the competition—it’s about driving innovation that meets customer demands, supports sustainability, and creates lasting value. With Augie, manufacturers have the clarity and confidence they need to make investments that matter.

Looking Ahead

Deloitte’s 2025 Manufacturing Industry Outlook offers a vision of both challenge and opportunity, and we at Augmentir couldn’t be more excited about the road ahead. The future of manufacturing is one of resilience, efficiency, and innovation—and AI is the key to unlocking it.

With Augie, manufacturers can tackle their toughest challenges and turn them into opportunities for growth. From labor shortages to rising costs, from digital transformation to strategic innovation, Augie is more than just a tool—it’s a trusted partner in navigating the complexities of the modern manufacturing landscape.

Are you ready to transform your operations and embrace the future of manufacturing? Let’s connect. Together, we can build a smarter, stronger, and more sustainable industry that thrives in the face of change.