Learn how connected worker technology can help you standardize and digitize layered process audits for improved accuracy and better quality results.

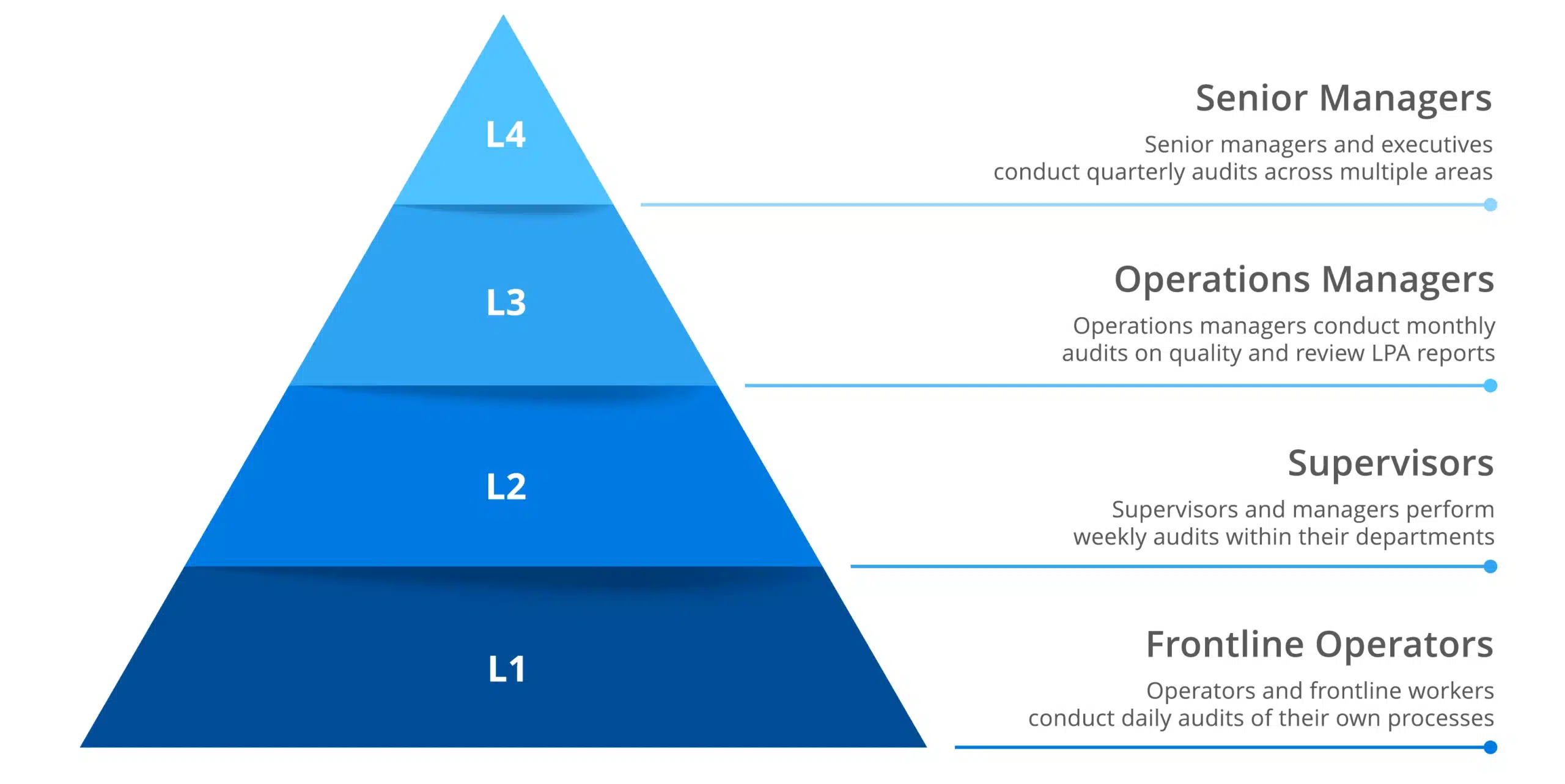

Digitized Layered Process Audits (LPAs) are important in manufacturing for establishing and enhancing process standardization, quality management, multi-level workforce engagement, risk mitigation, and quality standards compliance. The primary function of a Layered Process Audit is to focus on observing and validating how products are made to ensure process and product quality. This effectively protects manufacturers and frontline manufacturing personnel from defects and process issues before they can do any damage.

Many crucial manufacturing processes are still carried out using outdated pen-and-paper methods; and as the industry continues to evolve, digitization is essential to remain competitive and maintain proper quality and safety standards. Layered Process Audits are no exception, with digitized layered process audits now a necessity, rather than a luxury, for organizations looking to keep pace, elevate their audit processes, and meet the demands of the evolving industry.

Learn more about how to streamline LPAs with connected worker technology, implement digital LPAs, and the benefits of AI-powered analytics for digitized LPAs and overall quality management excellence in manufacturing below.

- Benefits of a Digitized Layered Process Audit

- Implementing Digital Layered Process Audits

- Driving Continuous Quality Improvement with Digitized LPAs

Benefits of a Digitized Layered Process Audit

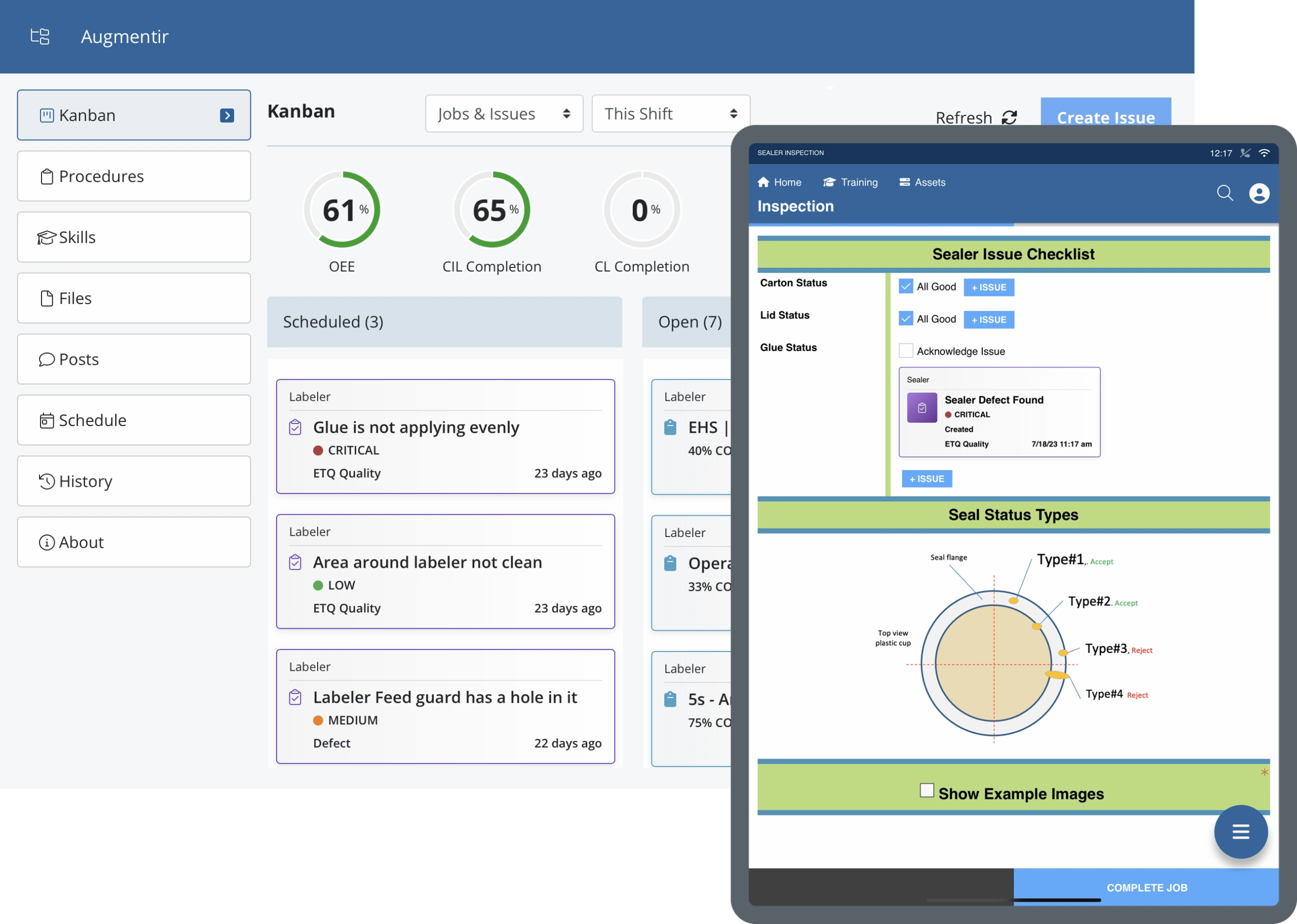

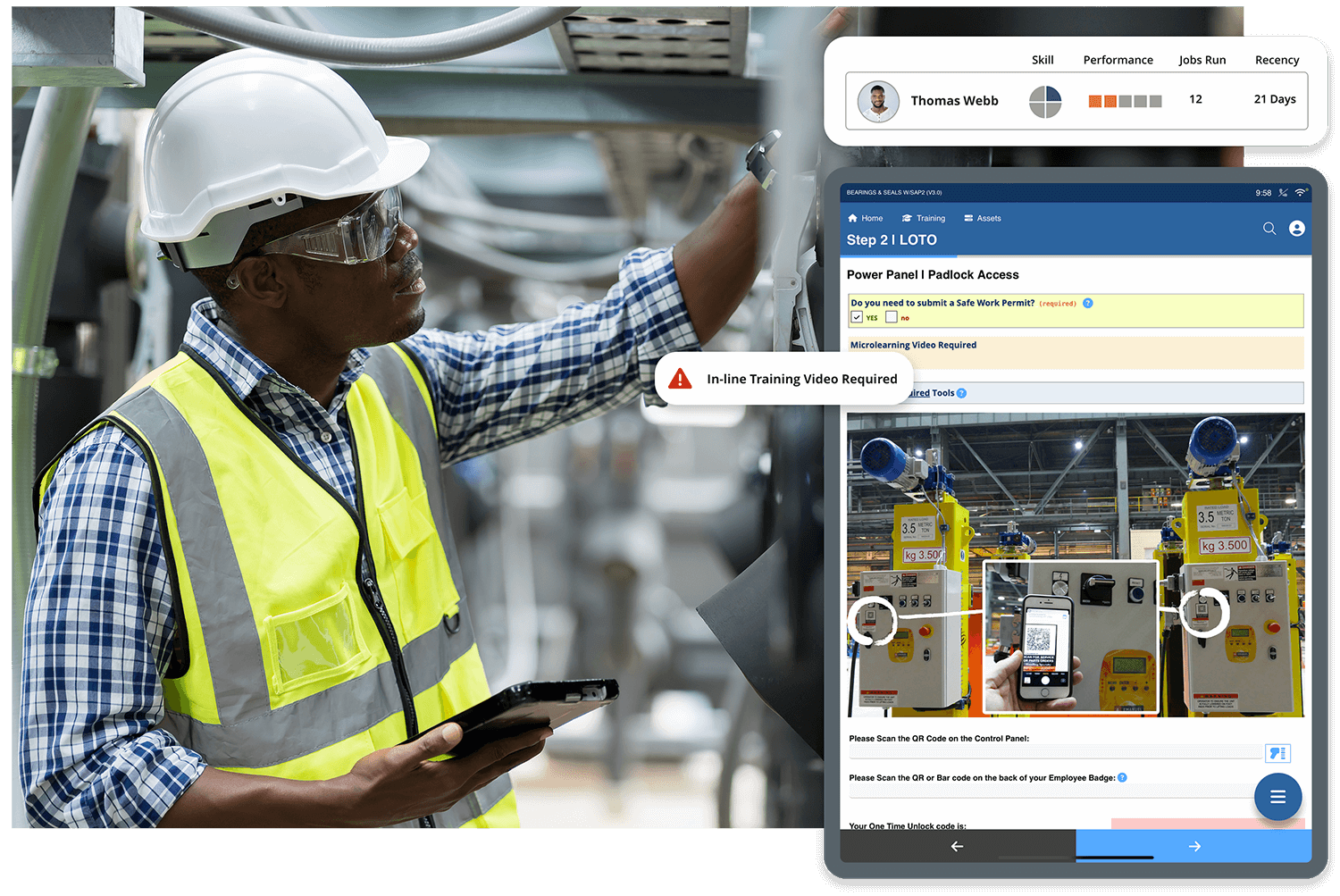

Connected worker platforms allow manufacturers to replace paper-based audit forms (like a layered process audit) with digital checklists that can be accessed and completed on mobile devices, allowing for:

- Standardized audit formats and best practices across audit layers

- Real-time data collection and improved audit tracking

- Mobile access to information and knowledge including relevant documents, procedures, and historical data

- Automated audit scheduling and notifications for consistent audit frequency across layers and reduced administrative burden

- Real-time issue reporting and escalation for faster response and issue resolution

- Improved data analytics and reporting to generate and apply insights as well as identify recurring issues and root causes

- Overall system integrations with things like ERP, MES, and CMMS

These abilities offer a significant boost to manufacturers in terms of operational efficiency, risk mitigation, workforce development, and cost reduction.

Implementing Digital Layered Process Audits

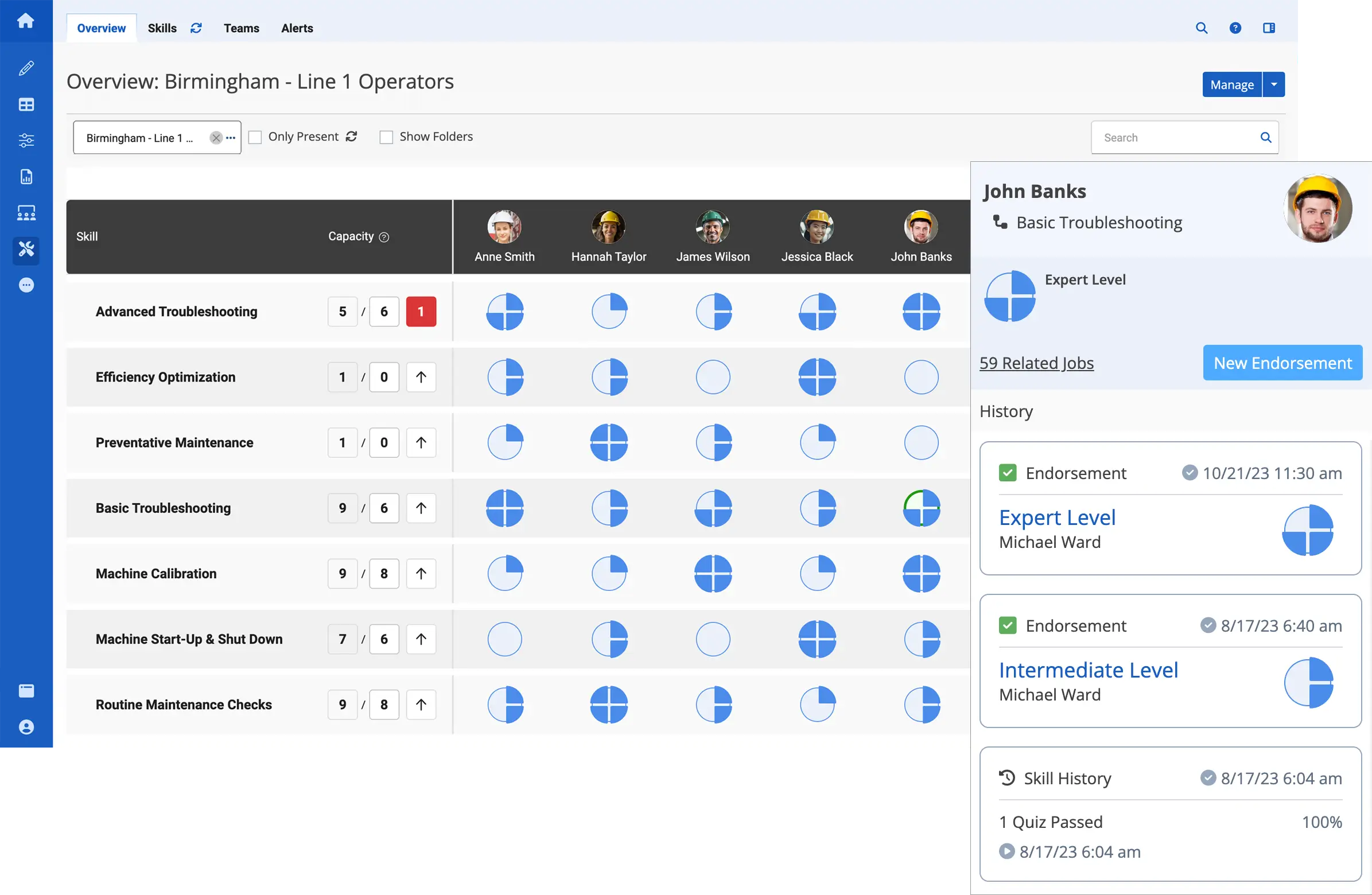

Manufacturers can digitize LPAs and streamline their quality management processes through AI-powered connected worker technologies, improving data quality and driving faster, more effective quality improvements across the organization.

Implementing digital Layered Process Audits (LPAs) involves several steps, from selecting the right platform to engaging the team and ensuring proper integration with existing systems. Below is a step-by-step guide to implementing digital LPAs effectively:

1. Choose the right Digital LPA Platform

Research and select a digital LPA platform that meets your organization’s needs. Consider factors like:

- Ease of use (especially for mobile devices)

- Customizability (to fit your audit checklist and process requirements)

- Integration with existing systems (e.g., ERP, quality management systems)

- Reporting and analytics capabilities

- Scalability for future needs

2. Develop and Digitize Audit Checklists

- Standardize Audit Checklists: Create or review the audit checklists for each layer of the audit process. Ensure they are aligned with your goals, operational requirements, and industry standards (e.g., ISO, IATF).

- Digitize the Checklists: Input these checklists into the digital platform. Ensure that they are tailored to different levels of the audit process, from shop floor employees to higher-level management.

- Customize Alerts and Criteria: Set up criteria for success/failure and alerts for non-conformance. This can include conditional triggers where a failed audit automatically prompts corrective actions.

3. Integrate with Other Systems

- Link to Quality Management Systems (QMS): Integrate the LPA platform with your existing QMS, ERP, or other relevant systems to streamline data sharing and analysis.

- Automate Corrective Action Processes: Ensure that non-conformance findings in the audit automatically trigger corrective action workflows, and link them to task management or follow-up procedures.

4. Monitor, Analyze, and Improve

- Track Real-time Results: Use the platform’s dashboards and analytics features to monitor performance metrics, such as audit completion rates, non-conformance trends, and the time taken to close corrective actions.

- Conduct Regular Reviews: Hold periodic review meetings with the audit team and management to discuss audit findings and trends. Use this information to drive continuous improvement in processes.

- Make Adjustments: Based on the insights from the audits, adjust the audit checklists, procedures, and corrective action plans as needed.

5. Foster a Culture of Continuous Improvement

- Encourage Engagement: Foster a culture where employees see the value in LPAs and actively participate in the process. Offer incentives or recognition for high levels of engagement or process improvements resulting from audits.

- Regularly Update the System: Keep the digital platform and audit processes updated to reflect changes in standards, regulations, or internal processes.

- Leverage Advanced Analytics: Over time, use advanced analytics and machine learning (if available) to predict potential non-conformance areas and further streamline corrective actions.

By following these steps, you can effectively implement a digital Layered Process Audit system that enhances visibility, accountability, and process control across your organization.

Driving Continuous Quality Improvement with Digitized LPAs

Excellence in quality management drives success in manufacturing. Digitizing and updating old processes with AI, connected worker platforms, and even simple digital layered process audit software allows manufacturing organizations to better identify and prevent defects at their source and protect against rework, customer complaints, costly product recalls, and reputational damage.

Recent innovations in AI technology and applications caused an explosion of growth all across the world and in various industries. Manufacturing is uniquely situated to adopt these technologies for massive growth. One valuable use case is the use of AI to optimize quality management, specifically to optimize audit processes like LPAs for drastically improved results and insights that simply weren’t possible previously.

AI analytics combined with connected worker technologies digitize and streamline layered process audits allowing manufacturers to capitalize on data capture for:

- Trend analysis across different audit layers, departments, and locations

- Automated population of audit forms with relevant data

- Seamless creation of digital work instructions from audit findings

- Application of cobots, generative AI assistants, or AI copilot technologies to support auditors and workers alike.

But this does not stop there, according to a study by McKinsey & Company, companies that prioritize quality management achieve higher levels of employee engagement. Engaged employees are more likely to be committed to producing high-quality products, resulting in increased productivity and customer satisfaction. The addition of AI to capitalize on connected worker data and feedback to generate insights, support enhanced decision-making, and create better processes offers manufacturers a path forward into the future with a better-equipped and supported frontline workforce.

Interested in learning more?

If you’d like to learn more about how Augmentir streamlines and optimizes quality management processes like digital layered process audits and more, schedule a demo with one of our produce experts.