Today’s dynamic and changing manufacturing workforce needs continuous learning and performance support to effectively sustain and deliver effective on-the-job performance.

Every day we hear about the growing manufacturing “Skills Gap” associated with the industrial frontline workforce. The story is that 30% of workers are retiring in the near future and they are taking their 30+ years of tribal knowledge with them, creating the need to quickly upskill their more junior replacements. In an attempt to solve the knowledge gap issues, an entire generation of companies set out to build “Connected Worker” software applications, however, they all relied on the existing training, guidance, and support processes – the only true difference with this approach has been the creation of technology that takes your paper procedures and puts them on glass.

Along with tribal knowledge and tacit knowledge leaving, today’s workforce is also more dynamic and diverse than previous generations. The 30-year dedicated employees are no longer the norm. The average manufacturing worker tenure is down 17% in the last 5 years and the transient nature of the industrial worker is quickly accelerating. An outgrowth of the COVID pandemic brings forth the Great Resignation, where workers are quitting in record numbers, and worker engagement is down almost 20% in the last 2 years.

This new manufacturing workforce is changing in real-time – who shows up, what their skills are, and what jobs they need to do is a constantly moving target. The traditional “one size fits all” approach to training, guidance, and performance support is fundamentally incapable of enabling today’s workers to function at their individual peak of safety, quality and productivity.

Digitizing work instructions is a great start to helping close the manufacturing skills gap, but alone, it won’t help completely solve the problem. We must go a step further to overcome the lack of a skilled and qualified manufacturing workforce.

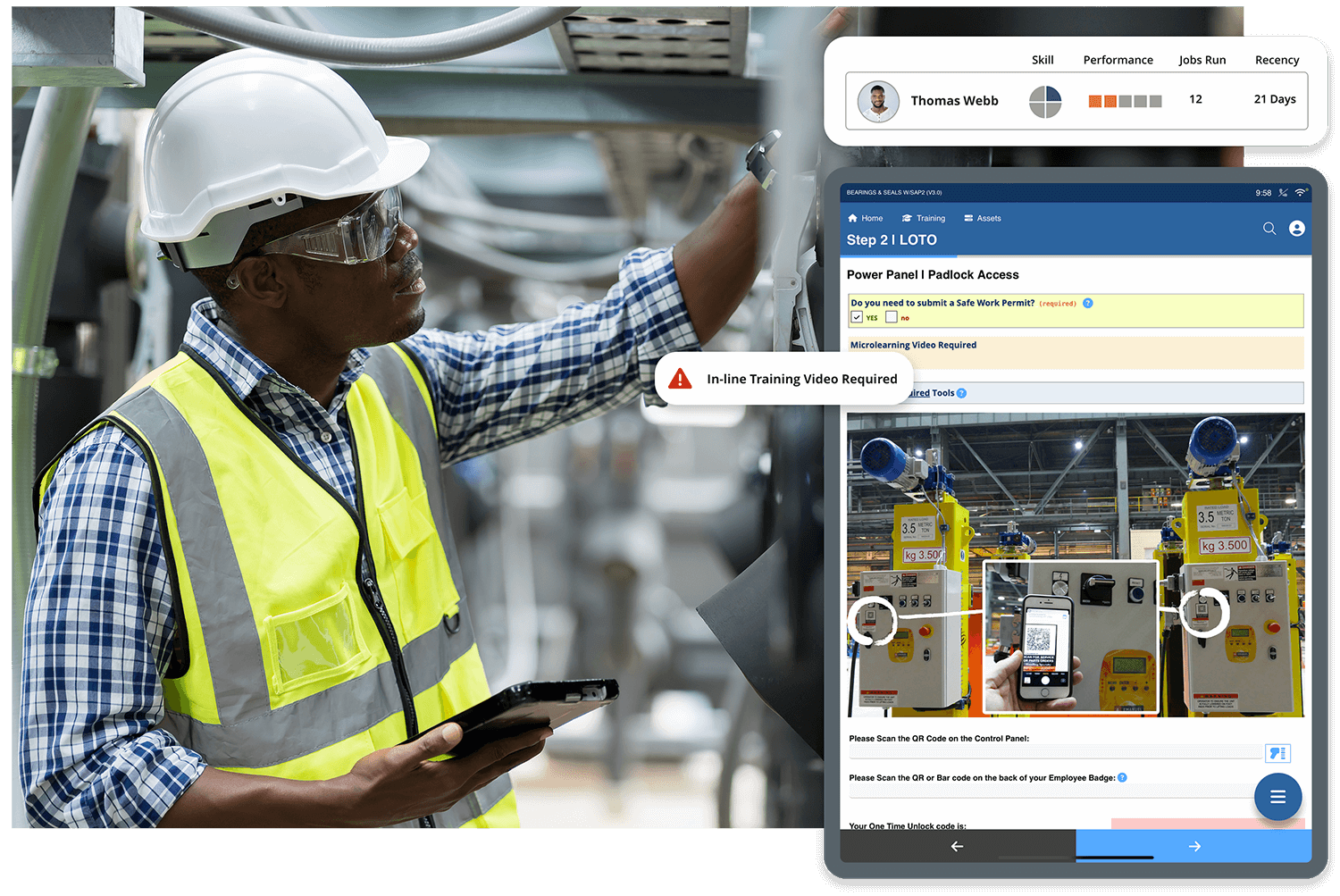

Enter the 2nd generation of Connected Worker software, one based on a data-driven, AI-supported approach that helps train, guide, and support today’s dynamic workforces by combining digital work instructions, remote collaboration, and advanced on-the-job training capabilities.

These 2nd generation connected worker solutions are designed to capture highly granular data streaming from connected frontline workers. These platforms are built from the ground up on an artificial intelligence (AI) foundation. AI algorithms are ideal for analyzing large amounts of data collected from a connected workforce. AI can detect patterns, find outliers, cleanse data and find correlations and patterns that can be used to identify opportunities for improvement and creates a data-driven environment that supports continuous learning and performance support.

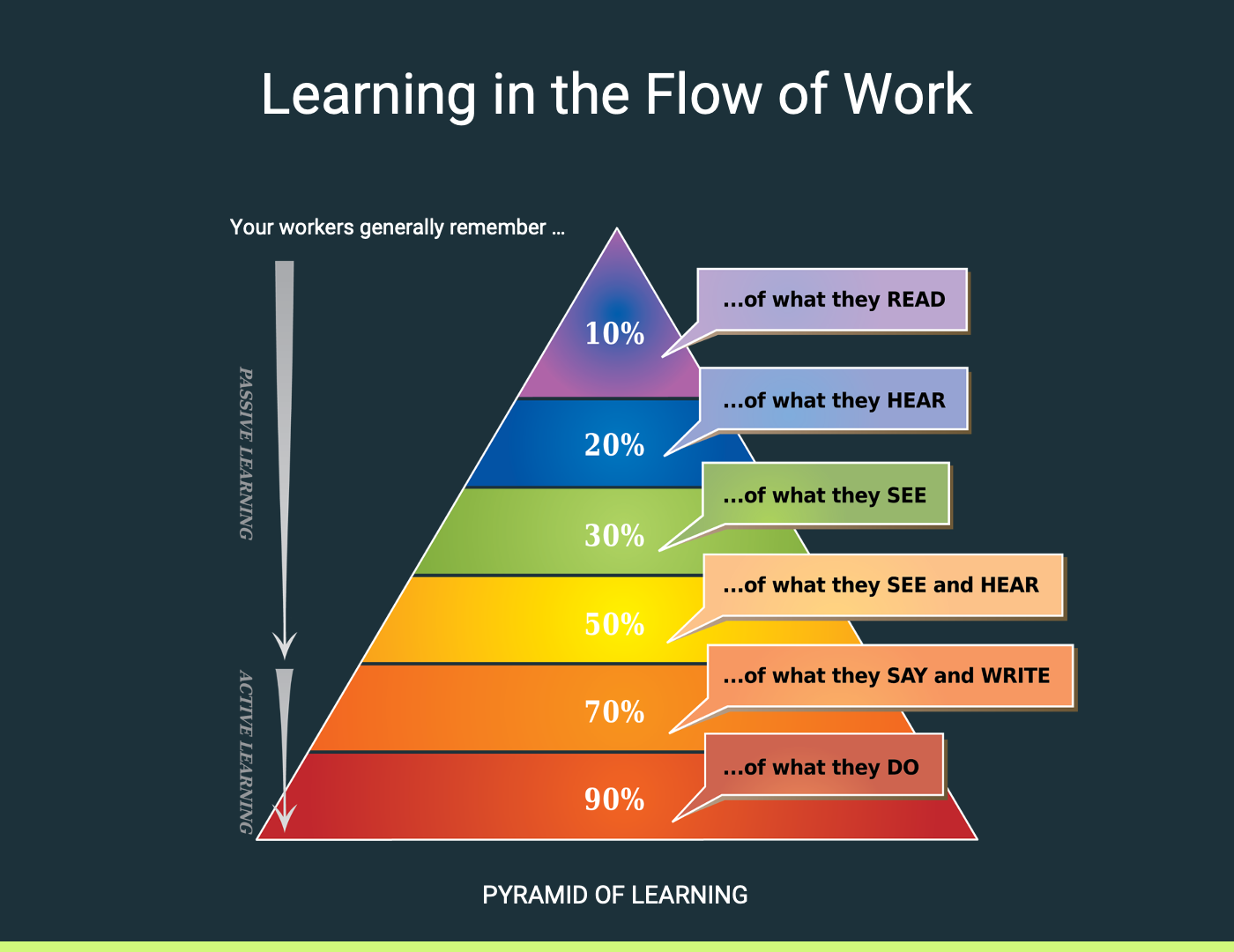

This approach aligns perfectly with the dynamic, changing nature of today’s workforce, and is ideally suited to support their 5 Moments of Need, a framework for gaining and sustaining effective on-the-job performance.

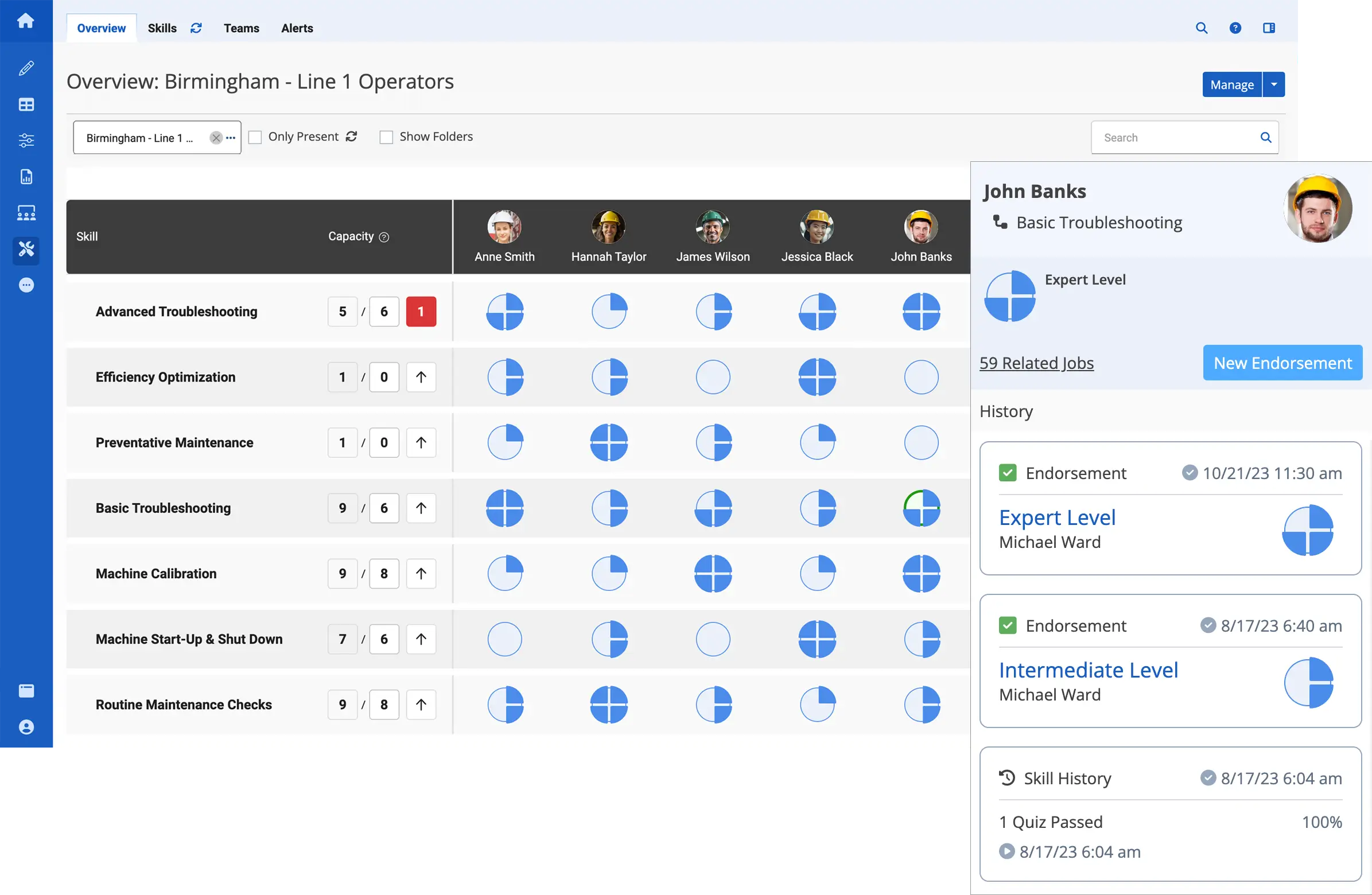

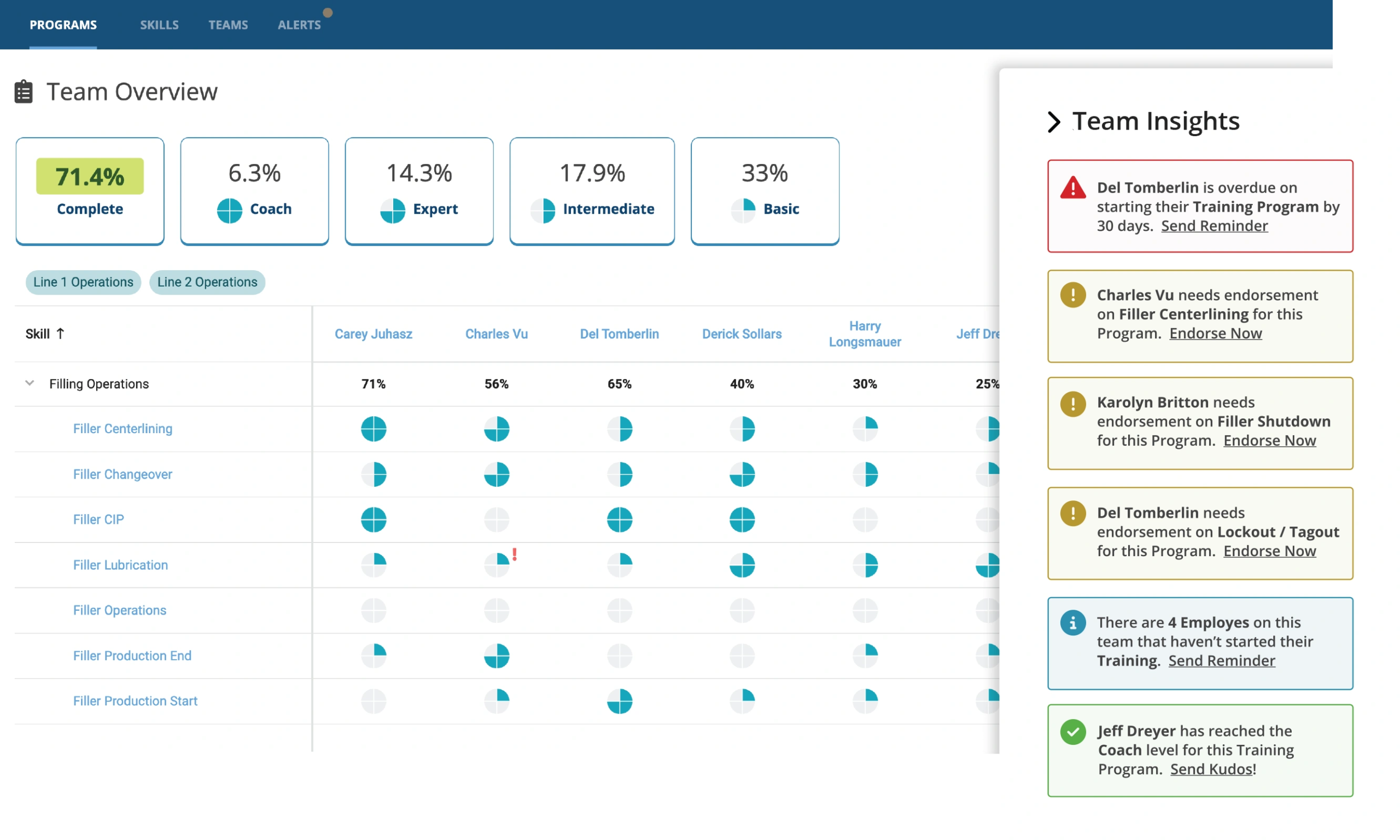

For example, Augmentir’s AI-powered connected worker platform leverages anonymized data from millions of job executions to significantly improve and expand its ability to automatically deliver in-app AI insights in the areas of productivity, safety, and workforce development. These insights are central to Augmentir’s True Proficiency™ scoring, which helps to objectively baseline each of your team members for their level of proficiency at every task so organizations can optimize productivity and throughput, intelligently schedule based on proficiency and skill-levels, and personalize the level of guidance and support to meet the needs of each member of the workforce.

This provides significant benefits to Augmentir customers, who leverage Augmentir’s AI in conjunction with the platform’s digital workflow and remote collaboration capabilities, allowing them to deliver continuous improvement initiatives centered on workforce development. These customers are able to utilize the insights generated from Augmentir’s AI to deliver objective performance reviews, automatically identify where productivity is lagging (or has the potential to lag), increase worker engagement, and deliver highly personalized job instructions based on worker proficiency.

Traditionally, there was a clear separation between training and work execution, requiring onboarding training to encompass everything a worker could possibly do, extending training time and leading to inefficiencies. Today, with the ability to deliver training at the moment of need, onboarding can focus on everything a worker will probably do, identifying and closing skills gap in real-time and significantly reducing manufacturing onboarding times. In one particular case, Bio-Chem Fluidics was able to reduce onboarding time for new employees by up to 80%, while simultaneously achieving a 21% improvement in job productivity across their manufacturing operation.

As workers become more connected, companies have access to a new rich source of activity, execution, and tribal data, and with proper AI tools can gain insights into areas where the largest improvement opportunities exist. Artificial Intelligence lays a data-driven foundation for continuous improvement in the areas of performance support, training, and workforce development, setting the stage to address the needs of today’s constantly changing workforce.