Learn how manufacturers combat the manufacturing skilled labor shortage and close skills gaps with an Augmented Connected Workforce (ACWF).

An Augmented Connected Workforce (ACWF) offers manufacturing and other industrial organizations a powerful solution to combat the ever-worsening skilled labor shortage and skills gap. According to a report by Deloitte and the Manufacturing Institute, an estimated 2.1 million manufacturing jobs could go unfilled by 2030 and the cost of those missing jobs could potentially total $1 trillion in 2030 alone.

By integrating advanced technologies like artificial intelligence (AI), connected worker platforms, and other emerging solutions manufacturers can enhance the capabilities of their existing workforce and bridge skill gaps. Connected worker tools offer real-time monitoring of your frontline workforce, ensuring seamless operations. Moreover, connectivity enables remote collaboration, allowing experts to assist frontline workers from anywhere in the world. This interconnected ecosystem empowers workers with the tools they need to succeed and attracts new talent by showcasing a commitment to innovation and technology-driven growth.

Through an ACWF, manufacturers can effectively combat the manufacturing skilled labor shortage and close the skills gap while driving productivity, innovation, and remaining competitive. Read more about ACWF in manufacturing below:

- Implementing an ACWF in Manufacturing

- Supporting Learning in the Flow of Work

- Future-proofing manufacturing Operations with an ACWF

Implementing an ACWF in Manufacturing

A critical element of transitioning from a traditional workforce to an Augmented Connected Workforce (ACWF) is implementing and adopting new technologies and processes. Here are a few steps that can help with the adoption of ACWF technologies and smooth transitions in industrial settings:

- Step 1: Assess Current Processes – Organizations must understand existing workflows and identify areas where AI, connected worker platforms, and other ACWF technology can replace paper-based and manual processes to enhance efficiency and productivity.

- Step 2: Invest in Technology – Procure AI-driven analytics platforms, mobile technology, and wearable technology to enable real-time data collection and remote collaboration.

- Step 3: Training and Onboarding – Provide comprehensive training programs to familiarize workers with new technologies and workflows. Emphasize the importance of safety protocols and data privacy.

- Step 4: Pilot Programs – Start with small-scale pilot programs to test the effectiveness of the implemented technologies in real-world manufacturing environments. Target high-value use cases that can benefit from a transition from paper to digital.

- Step 5: Continuous Improvement – Gather feedback from workers and supervisors during pilot programs and adapt implementation initiatives based on their input. Continuously optimize processes and technologies for maximum effectiveness.

By following these steps, manufacturers can smooth the transition from a traditional manufacturing workforce to an ACWF, empowering their frontline workers with improved capabilities, skills, and overall operational excellence.

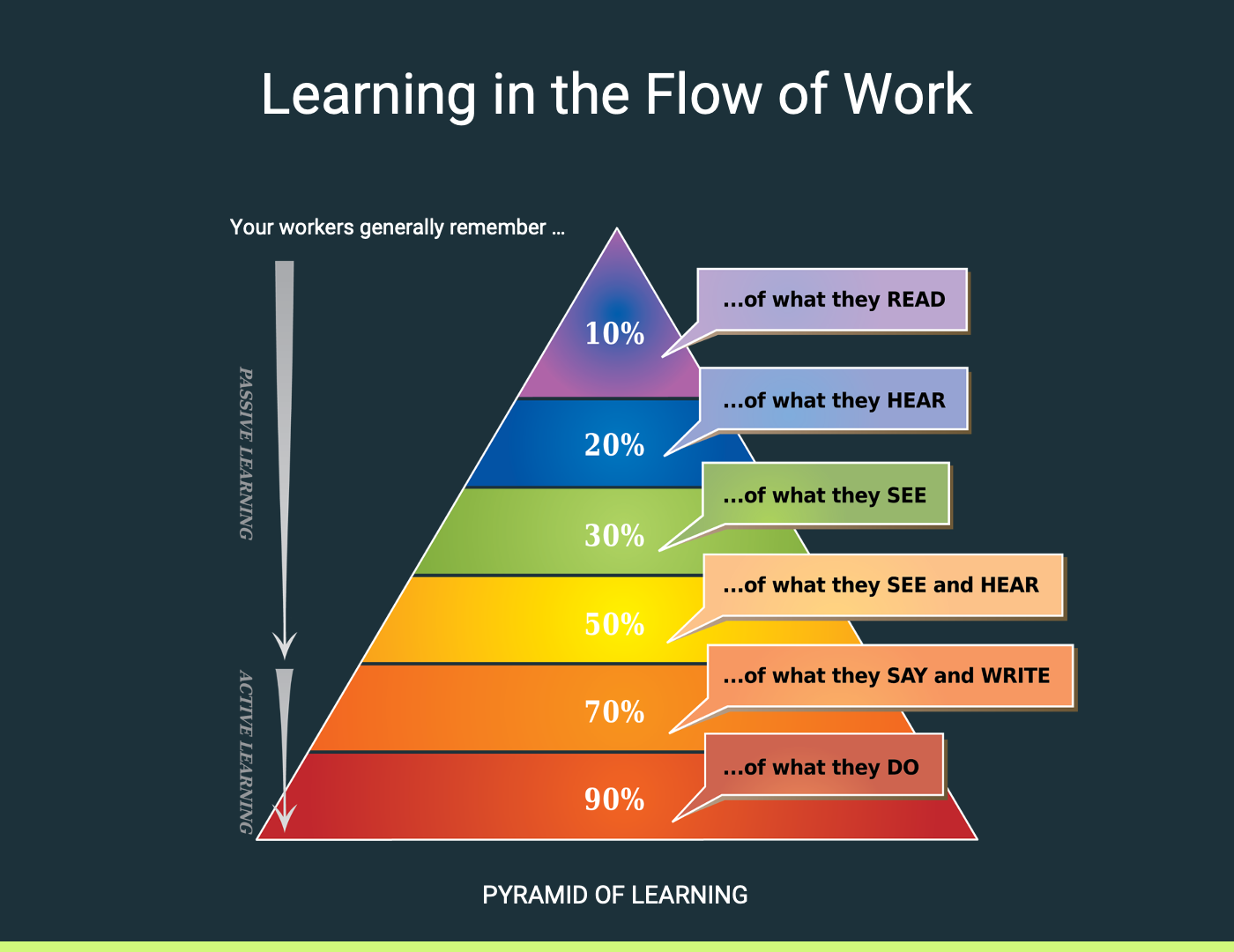

Supporting Learning in the Flow of Work

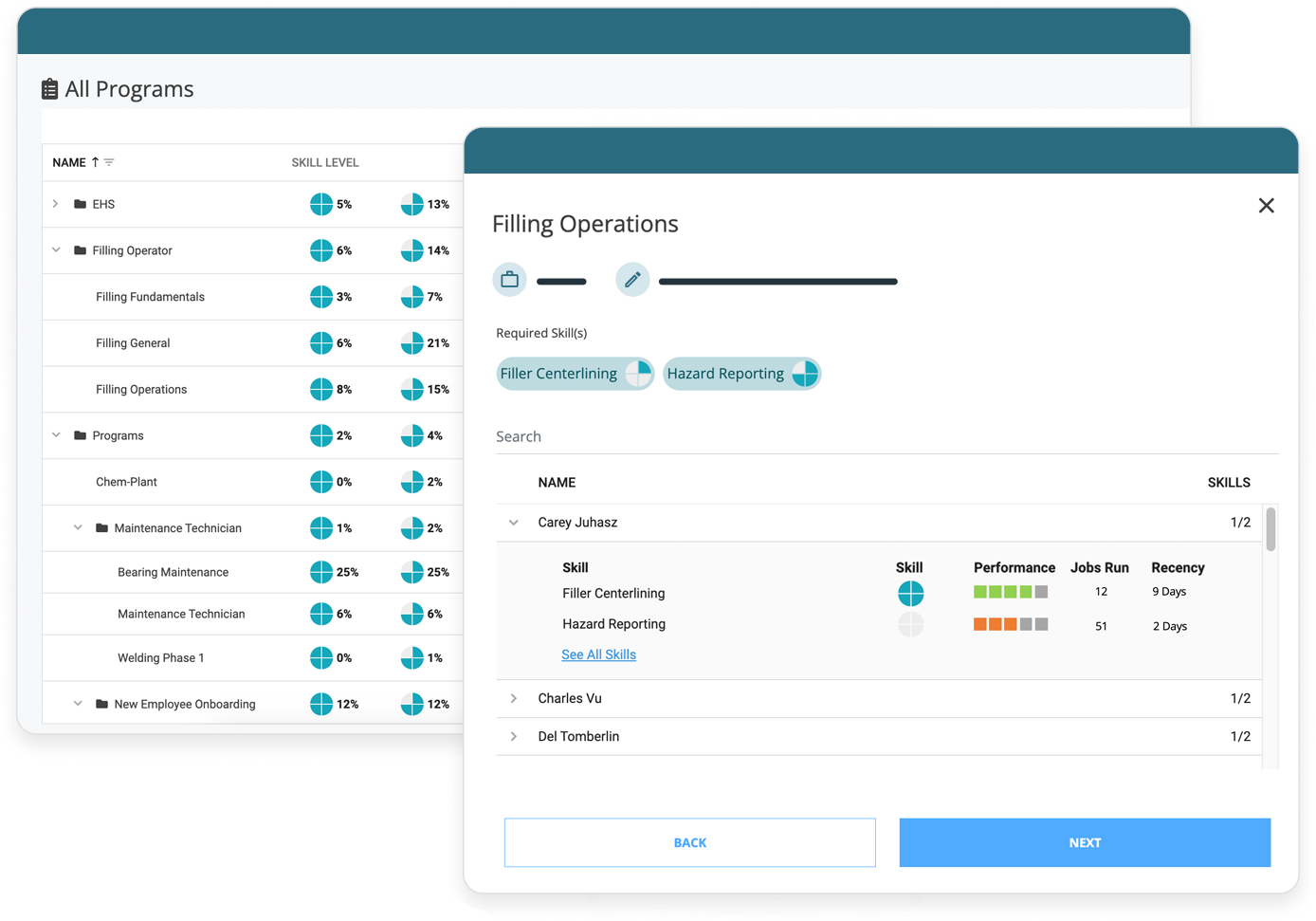

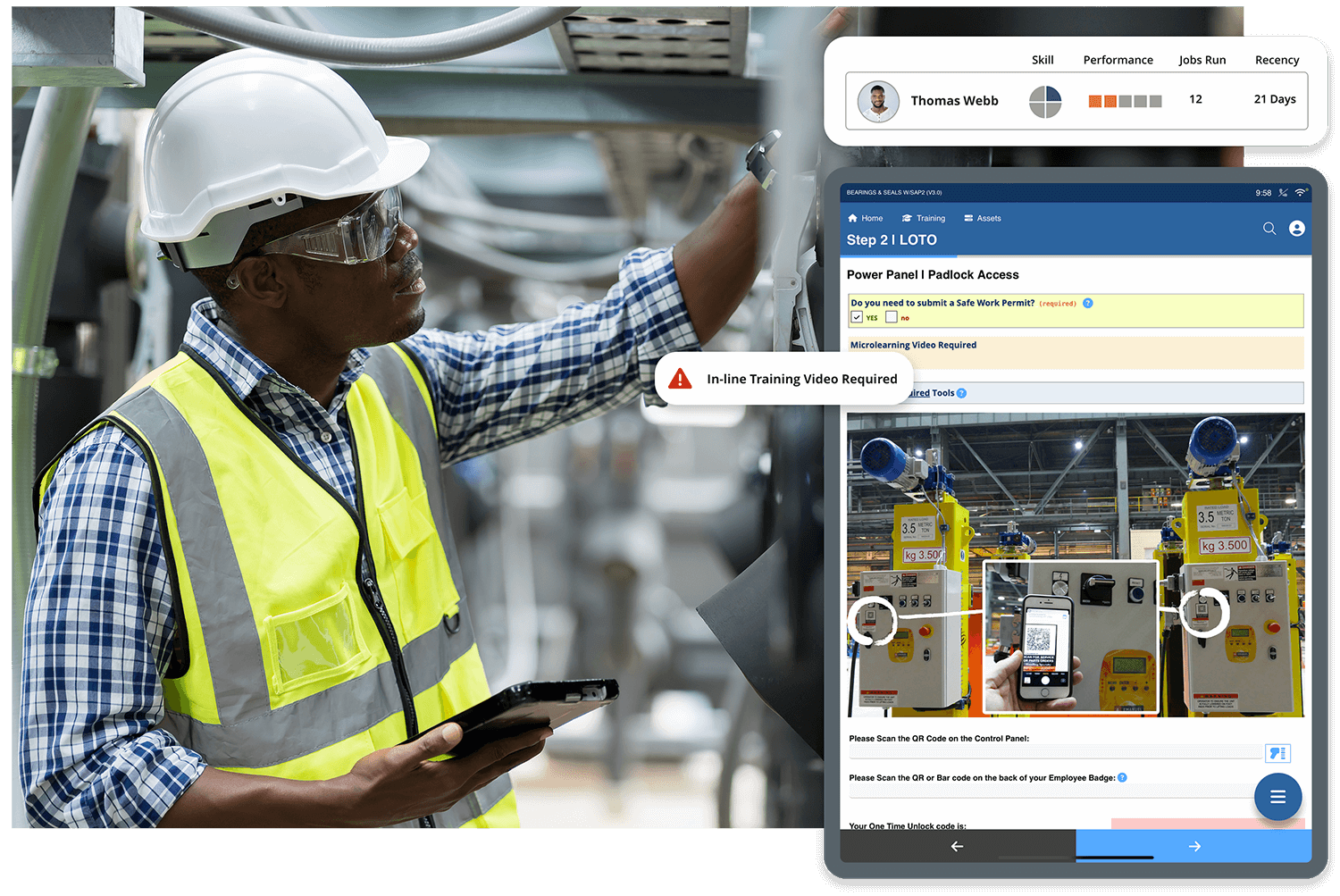

Augmented Connected Workforce (ACWF) technologies allow for increased frontline support and for new processes around learning and training to strategically upskill and reskill, reduce time to competency for new workers, and to combat the skilled labor shortage in manufacturing and more. Connected worker tools, such as wearable devices and IoT sensors, enable real-time monitoring of worker performance and environmental conditions, ensuring safety and efficiency on the factory floor.

An ACWF also allows for improved workflow learning capabilities giving frontline workers access to expert guidance, remote assistance and collaboration, microlearning, and other learning in the flow of work options regardless of the worker’s location.

ACWF tools further enhance frontline activities through:

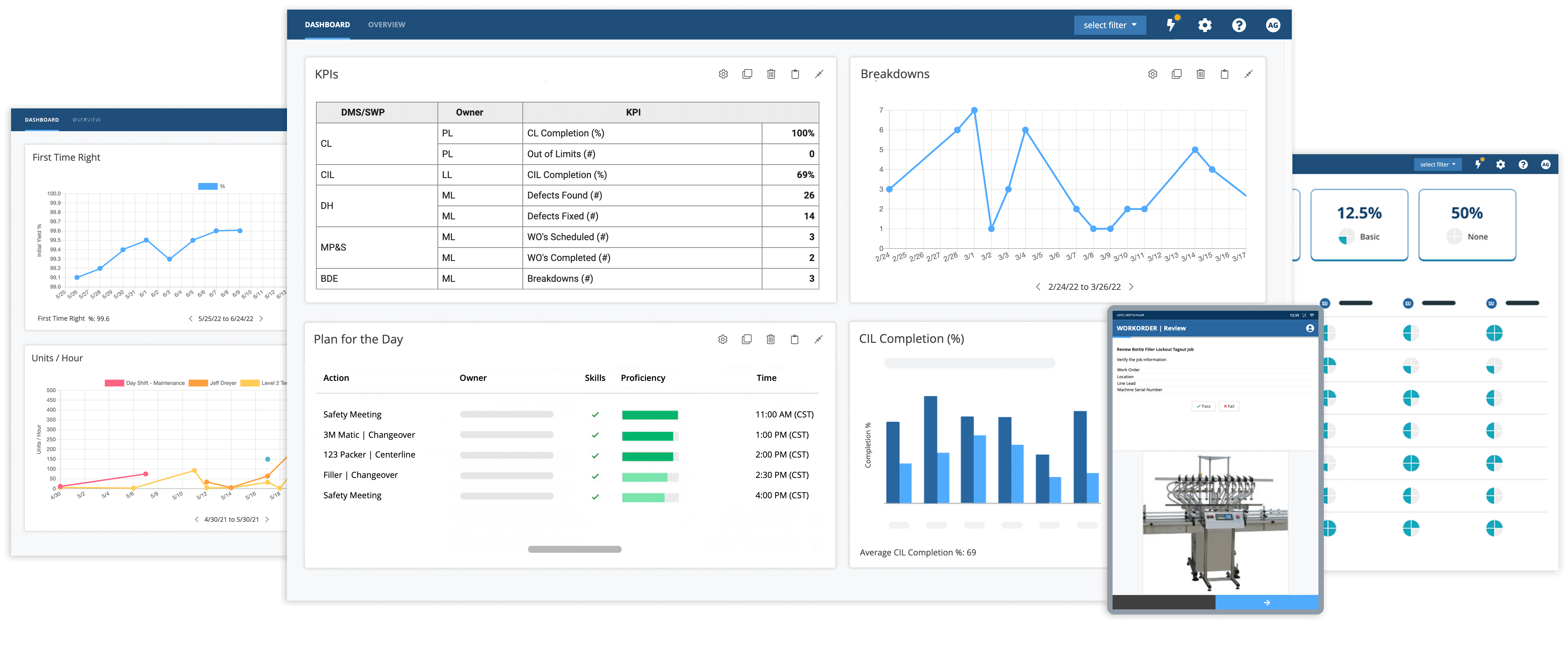

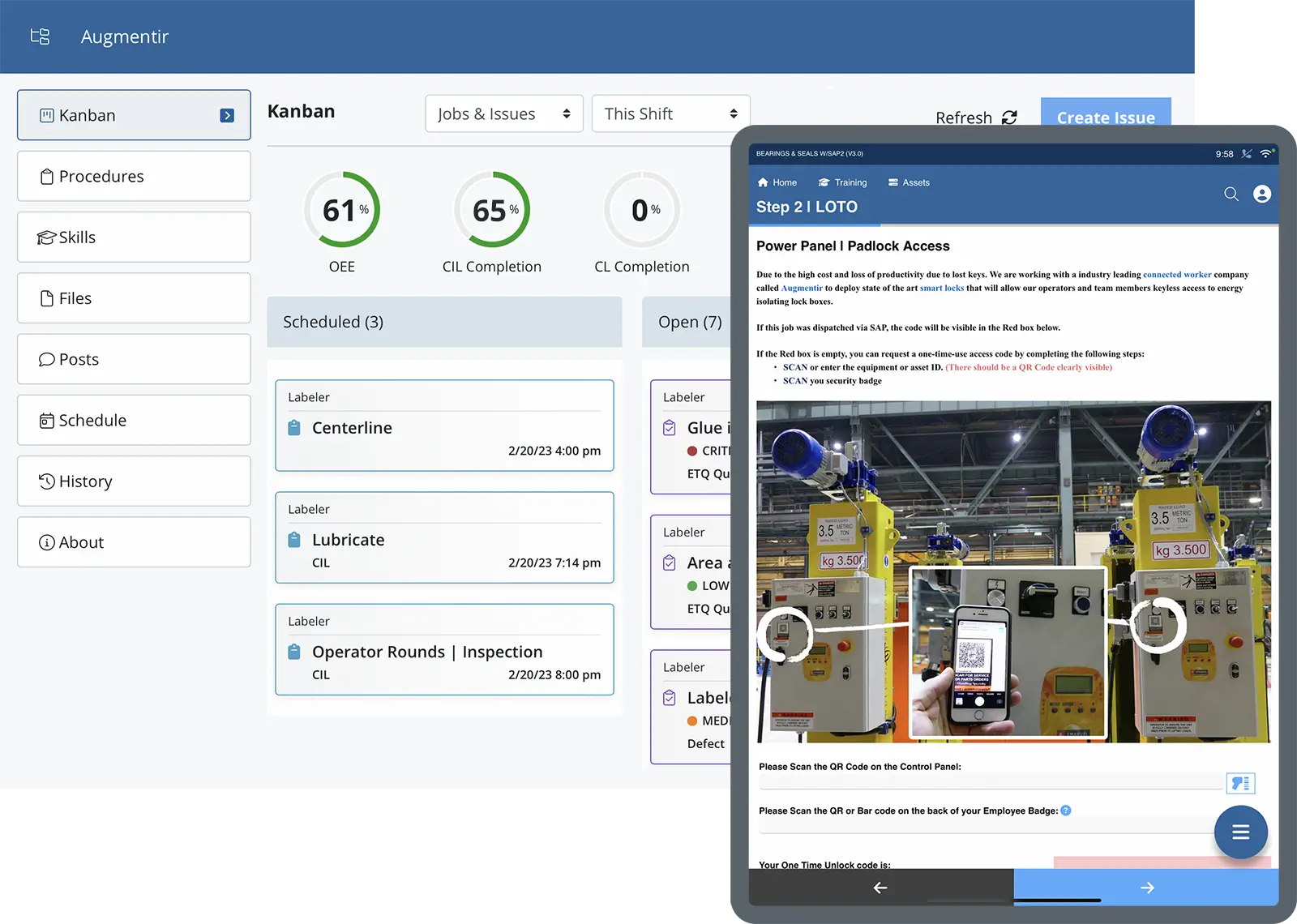

- Digital work instructions and guidance: Smart, connected worker platforms provide digital work instructions, procedures, and visual guidance easily accessible to workers on mobile devices.

- Digital mentors and training: Some ACWFs incorporate “digital mentors” – GenAI-powered industrial assistants that can provide step-by-step guidance to workers, especially new hires.

- Knowledge capture and sharing: Connected frontline worker applications capture data and insights from frontline workers, which can then be analyzed by AI software and used to improve processes, update work instructions, and share knowledge across the organization

- Performance monitoring and feedback: ACWF solutions provide visibility into worker performance, allowing managers to identify areas where additional training or support is needed.

In summary, ACWF initiatives empower frontline workers with the digital tools, knowledge, and support they need to learn and improve their skills directly within their daily workflows, rather than relying solely on formal training programs. This helps close skills gaps and drive continuous improvement.

Future-proofing Manufacturing Operations with an ACWF

Adopting an Augmented Connected Workforce (ACWF) approach centered around augmenting frontline workers with mobile technology, immersive training, collaborative decision-making, and continuous improvement, allows manufacturers to future-proof their operations and gain a sustainable competitive advantage. This concept empowers employees with powerful tools that augment and enhance their capabilities, productivity, and overall business processes by accessing critical information and fostering collaboration

AI-powered software can analyze vast amounts of data to optimize production processes and predict workforce development needs. At the same time, connected frontline worker solutions enable the integration of mobile and wearable technologies and provide real-time data insights, aiding in optimizing factory operations and adapting to evolving industry trends.

For an Augmented Connected Workforce, integrating AI and connected worker technologies serves as a vital strategy for manufacturers navigating the skilled labor crisis. Augmentir encourages organizations to embrace ACWF transformations and expedites adoption through a comprehensive connected worker platform leveraging the combined benefits of connected worker and AI technologies.

With Augmentir, frontline workers can access critical information, real-time data and insights, and expert advice and guidance all in the flow of work preventing lost time and improving both efficiency and productivity. Schedule a live demo to learn more about how an Augmented Connected Workforce future-proofs manufacturing operations and enhances frontline activities.