In conversations with our customers, a recurring theme emerges when discussing their transition to digital processes: the largest cost and burden often lies in the time and effort required to digitize existing paper-based materials.

In conversations we have with manufacturing companies, a recurring theme emerges when discussing their transition to a paperless operation: the largest cost and burden often lies in the time and effort required to digitize existing paper-based materials.

Standard Operating Procedures (SOPs), work instructions, and checklists are typically built over years, representing a significant repository of organizational knowledge. Converting these into digital formats while maintaining accuracy and accessibility can be daunting.

Customers frequently express concerns about the resource-intensive nature of this transformation. It’s not just about scanning documents; it’s about rethinking and structuring them for digital workflows. Many find themselves needing to allocate substantial time to review, update, and adapt content to ensure it aligns with current operational realities and integrates seamlessly into new platforms.

This challenge is real for any industrial company undergoing a transformation to digital manufacturing. It also represents an opportunity … and this is exactly why we created Augie.

The Power of GenAI in Digitizing Content

Generative AI (GenAI) has transformative potential for digitizing content by automating the conversion of paper-based materials into structured, digital formats. It can analyze and extract information from documents like SOPs, work instructions, or checklists, quickly translating them into editable, standardized templates. GenAI also enables content enhancement, such as rewriting for clarity, integrating visuals, language translation, or adapting content for specific workflows. By accelerating the digitization process and reducing manual effort, GenAI empowers organizations to transition to digital systems more efficiently and cost-effectively.

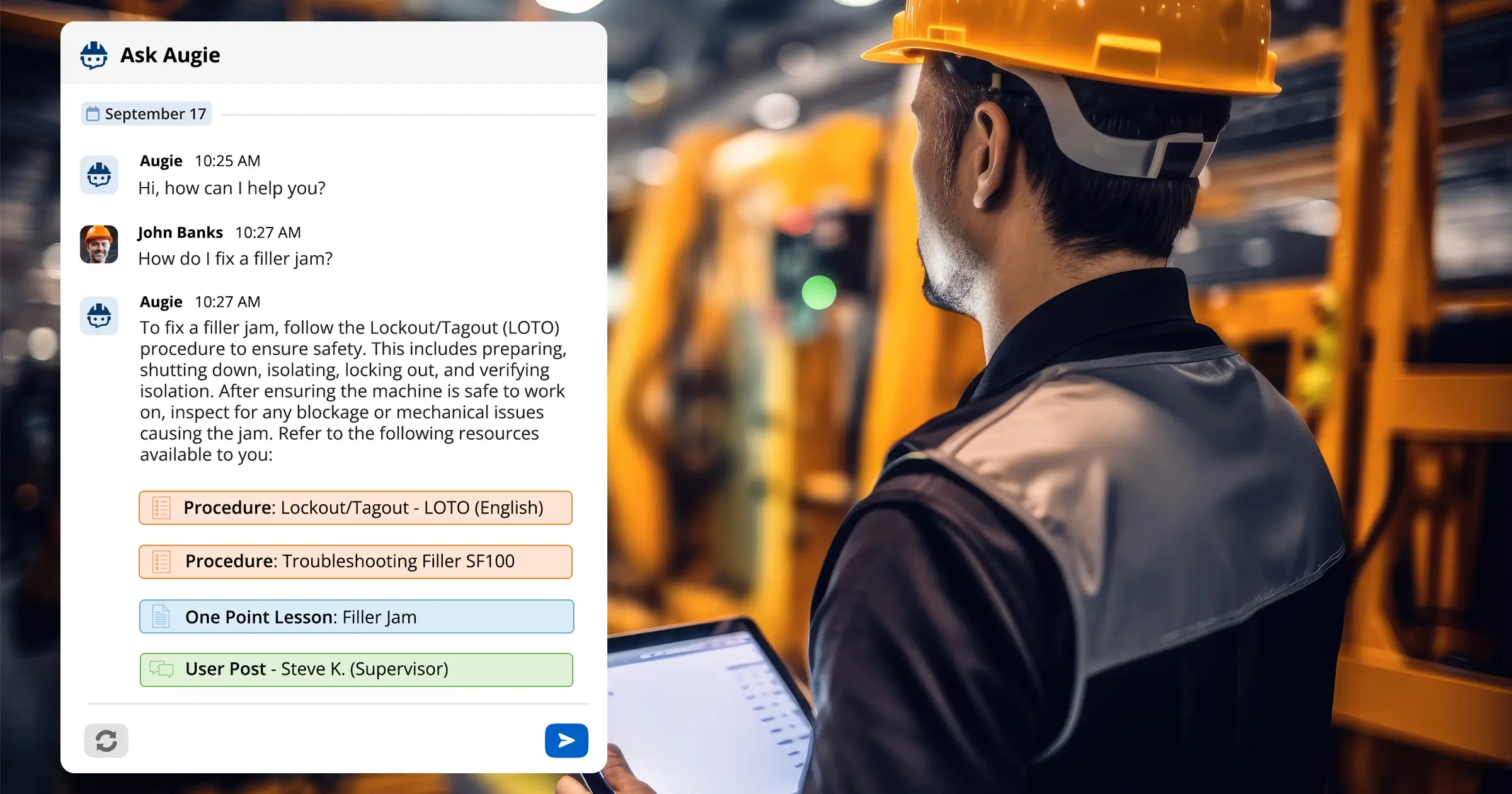

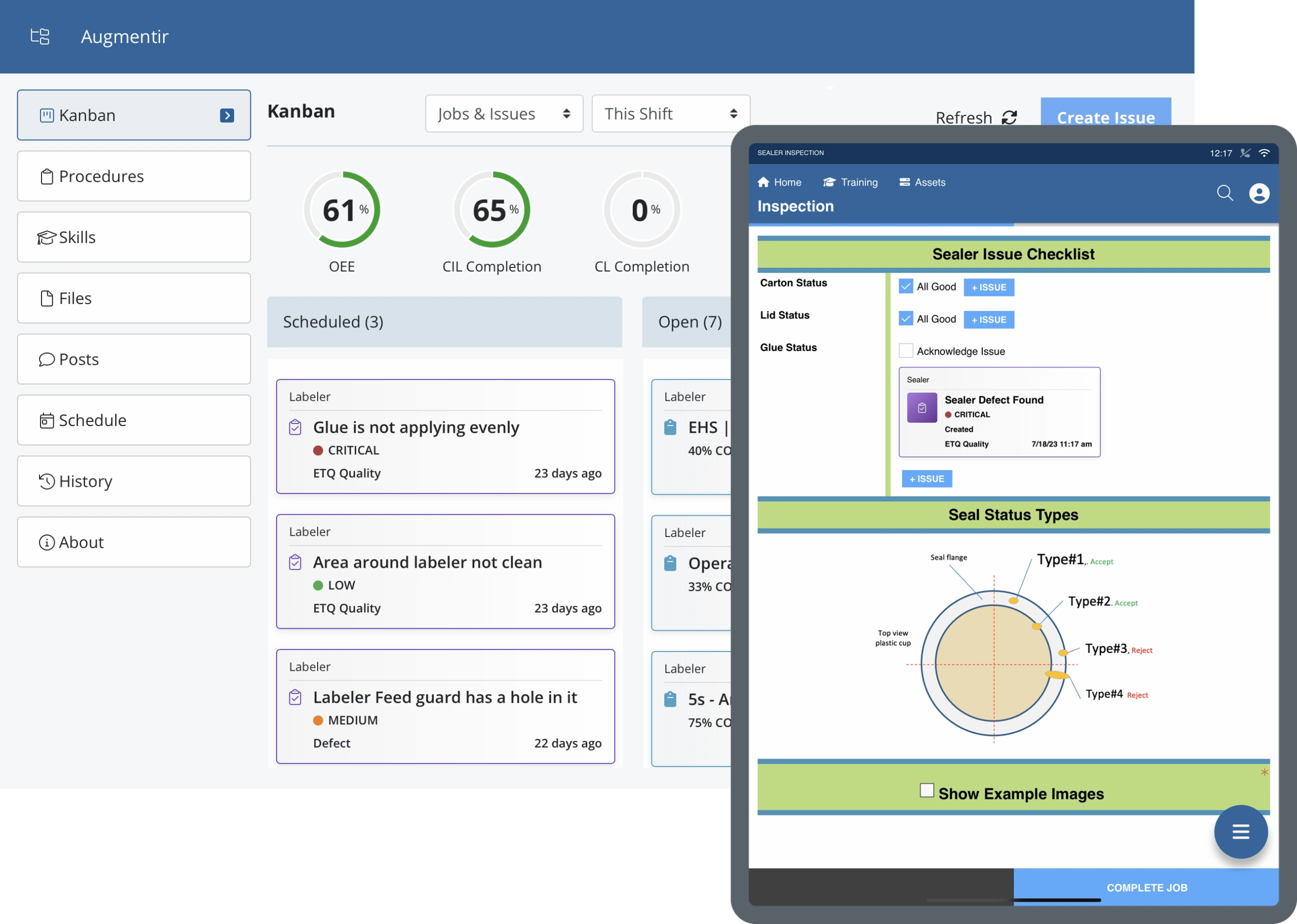

Augie, a suite of Industrial Generative AI tools from Augmentir, revolutionizes industrial digital transformation by combining advanced AI capabilities with practical, human-centric applications. Augie uses generative AI and the power of advanced Large Language Models (LLMs) to transform digital content creation, create adaptive workflows, provide real-time worker guidance, and analyze data to deliver actionable insights.

“

Augie has been instrumental in helping us quickly transform our existing paper-based SOPs and training documents into interactive digital work instructions and learning tools. We’ve reduced our digitization effort from months down to days. This has streamlined our processes, reduced errors, and accelerated the upskilling of our workforce.

Digital Transformation Lead

Fortune 100 Food & Beverage Manufacturer

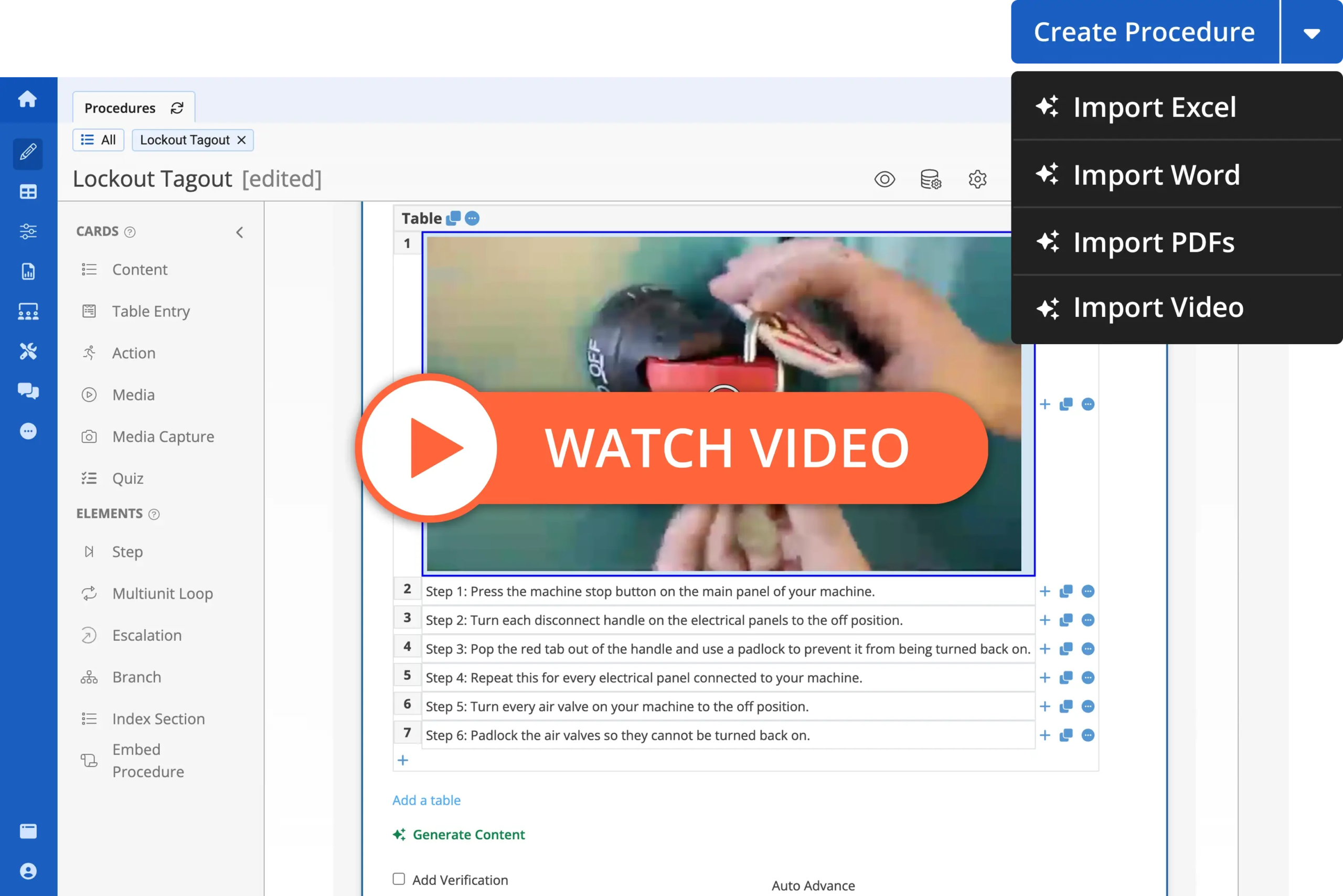

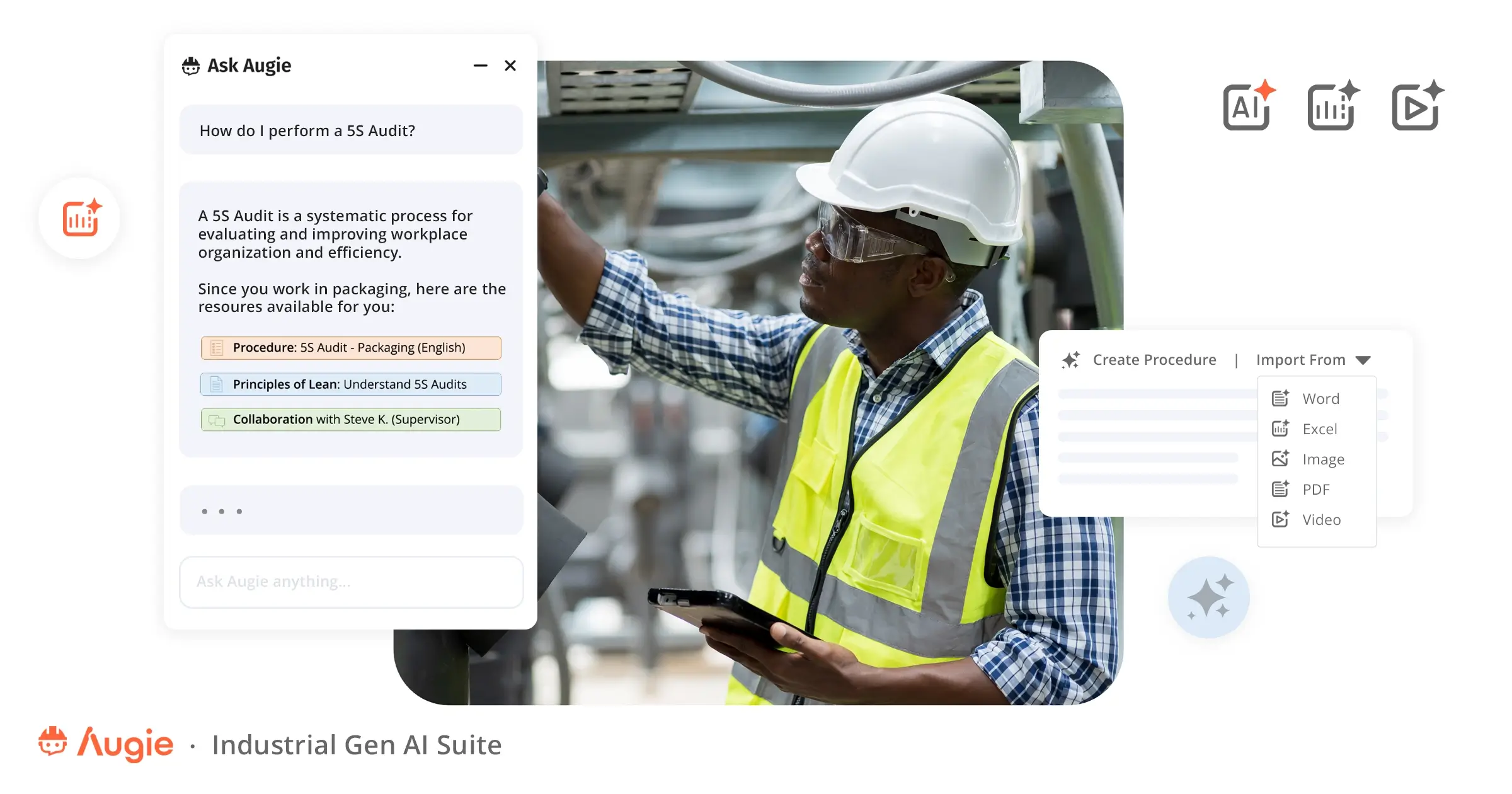

Augie for Procedure Creation

Augie is a powerful tool for accelerating the transition from paper-based to digital operations in manufacturing and industrial settings.

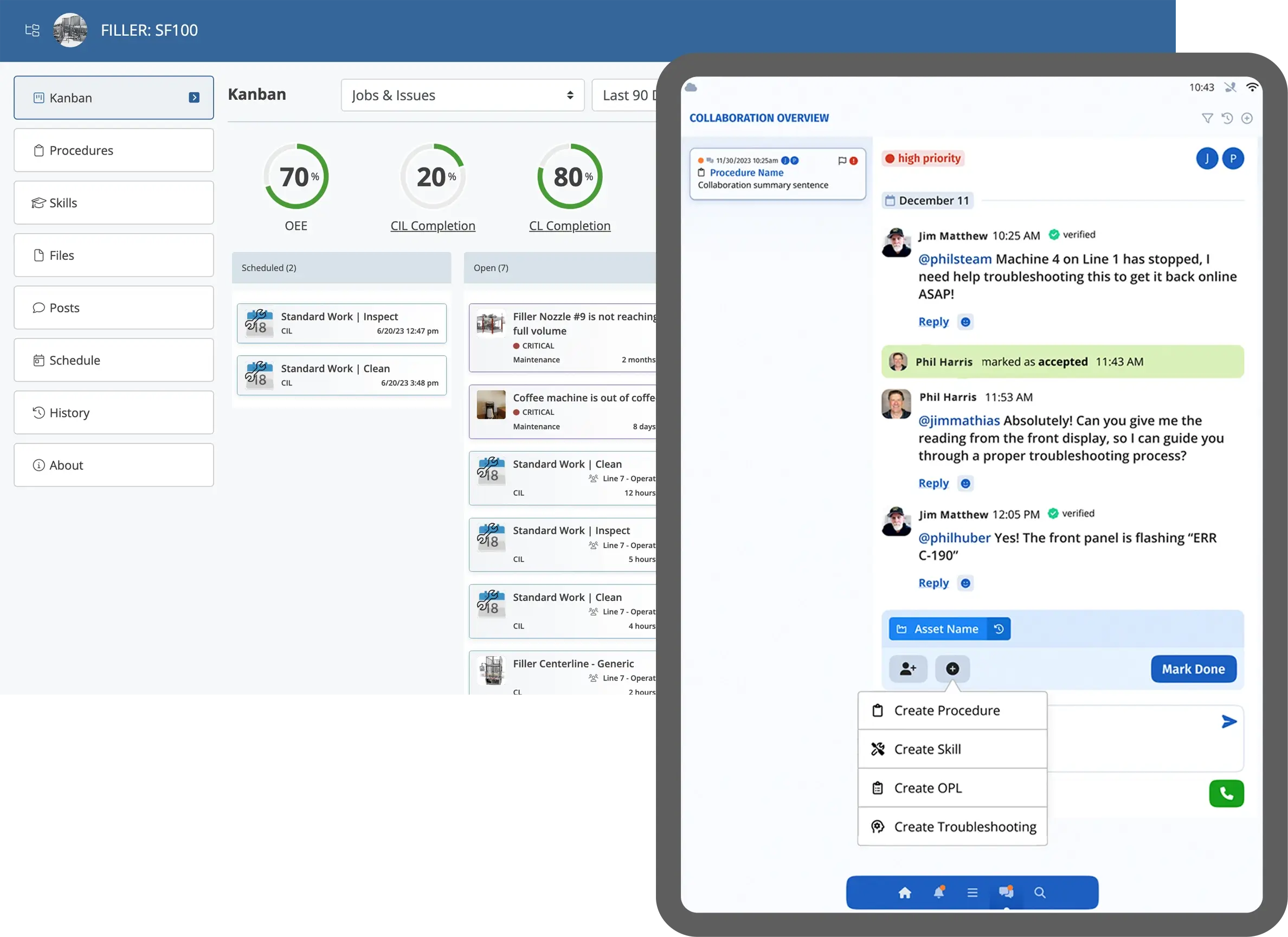

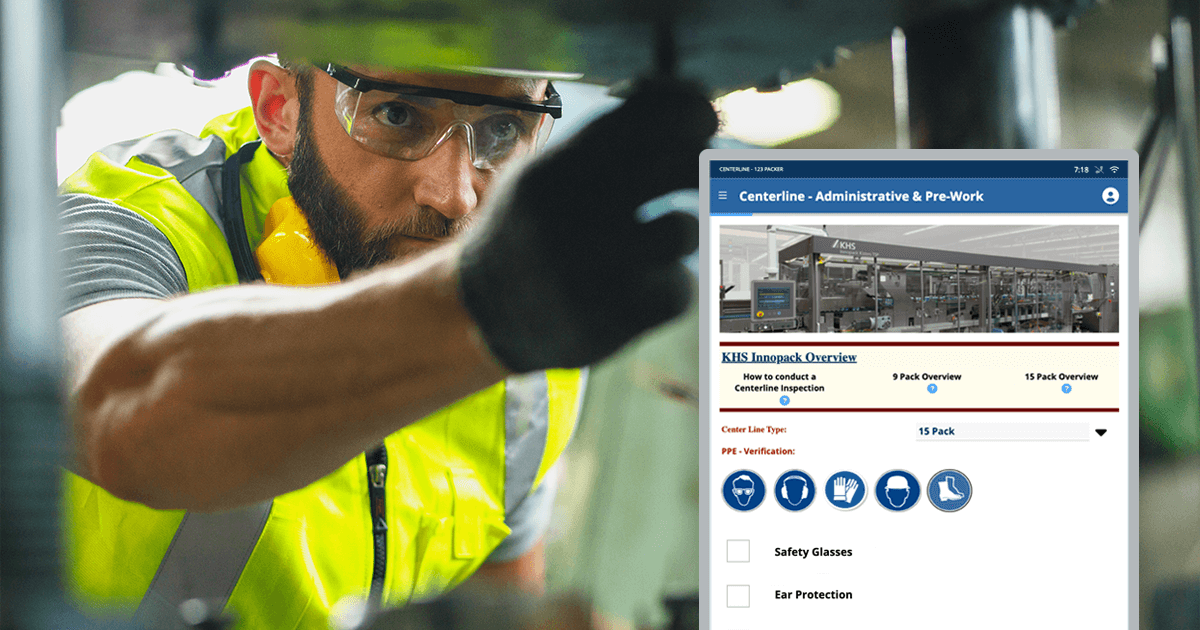

Quickly generate standard work procedures from Excel, Word, PDFs, images, or videos. The Augie Content Assistant takes your existing content and generates digital smart forms, checklists, and digital work instructions. Augie can summarize the exchange of tribal knowledge via collaboration and convert these to scalable, curated digital assets that can be shared instantly across your organization.

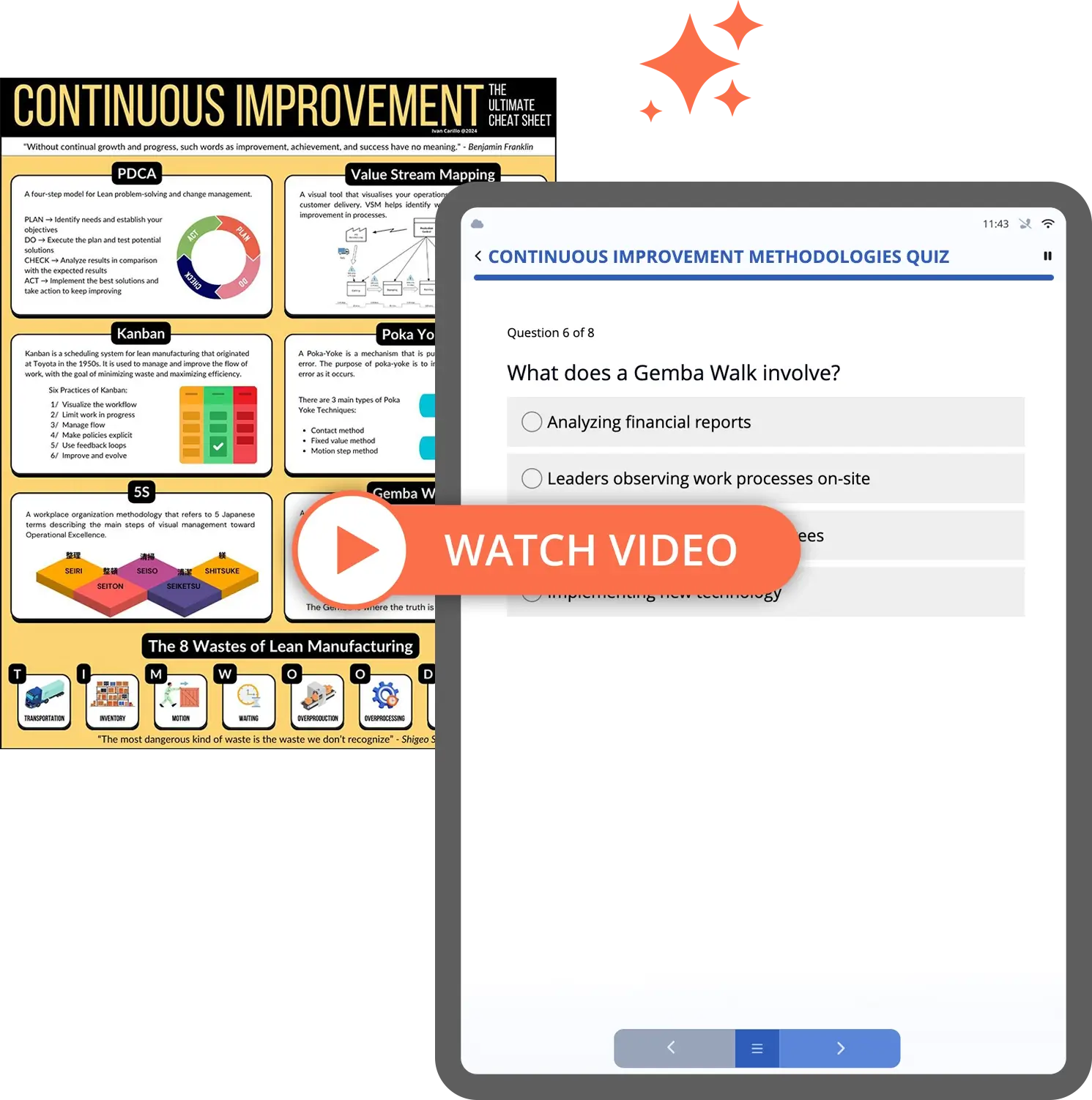

Augie for Training Content

Augie, Augmentir’s GenAI assistant, makes it easier to convert paper-based information into tailored training content and quizzes for today’s less experienced frontline workforce. Augie automatically analyzes SOPs, work instructions, and other documents to create clear, simplified training modules. It generates interactive quizzes to reinforce key concepts and adapts learning materials to individual skill levels, ensuring workers engage with relevant content.

By streamlining this process, Augie reduces the effort and time required to create effective, hands-on training tools for workforce development.

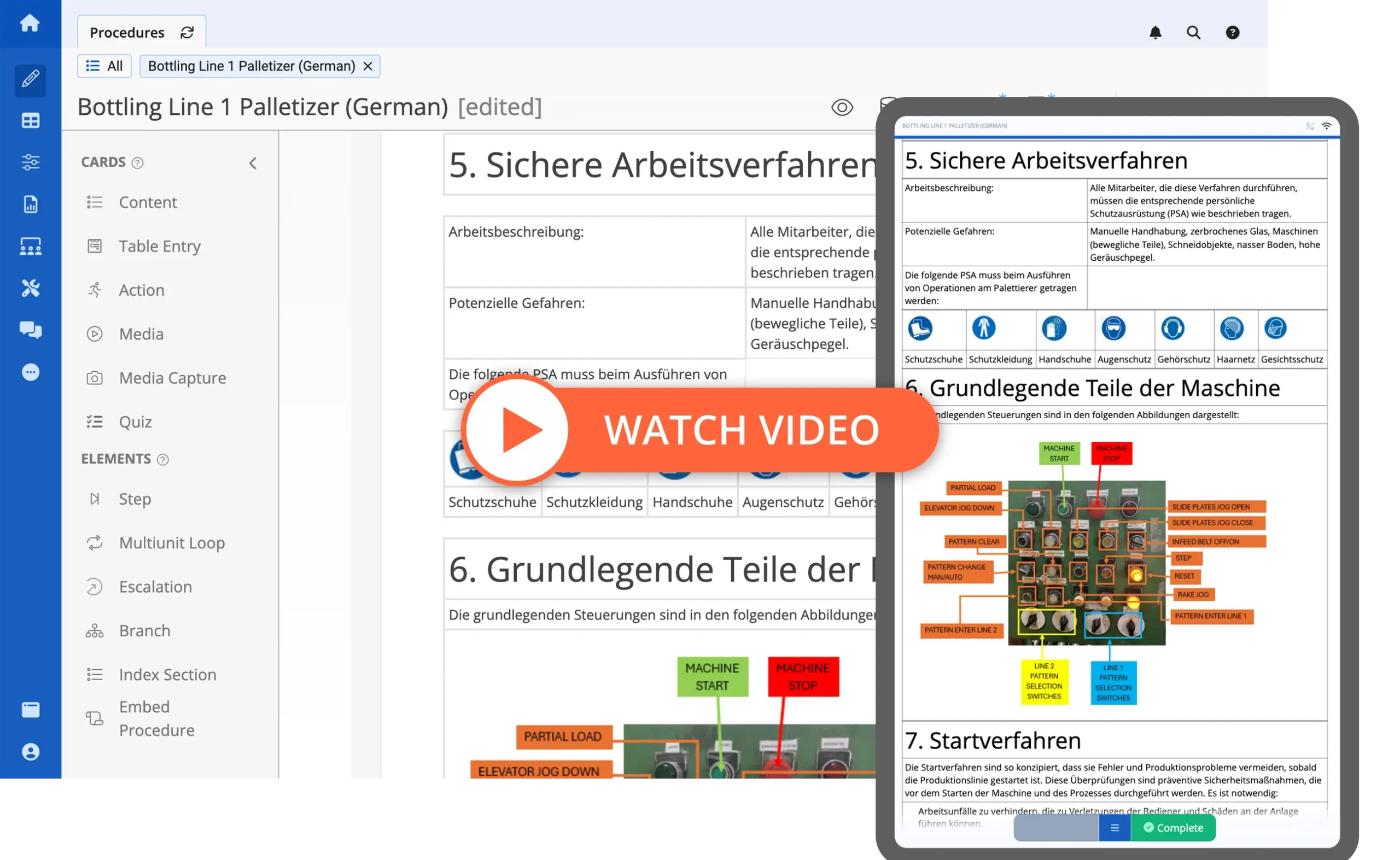

Augie for Content Localization

Language translation and localization are crucial for ensuring work instructions and training materials are effective and accessible for frontline workers in manufacturing and any industrial setting. Providing materials in a worker’s native language increases comprehension, reduces errors, and enhances safety.

With Augie, content localization is easy. Augie’s content localization tools make work instructions and training materials more relatable and actionable. This investment fosters better workforce performance, inclusivity, and compliance with global standards.

The Next Phase of AI in Manufacturing is Here

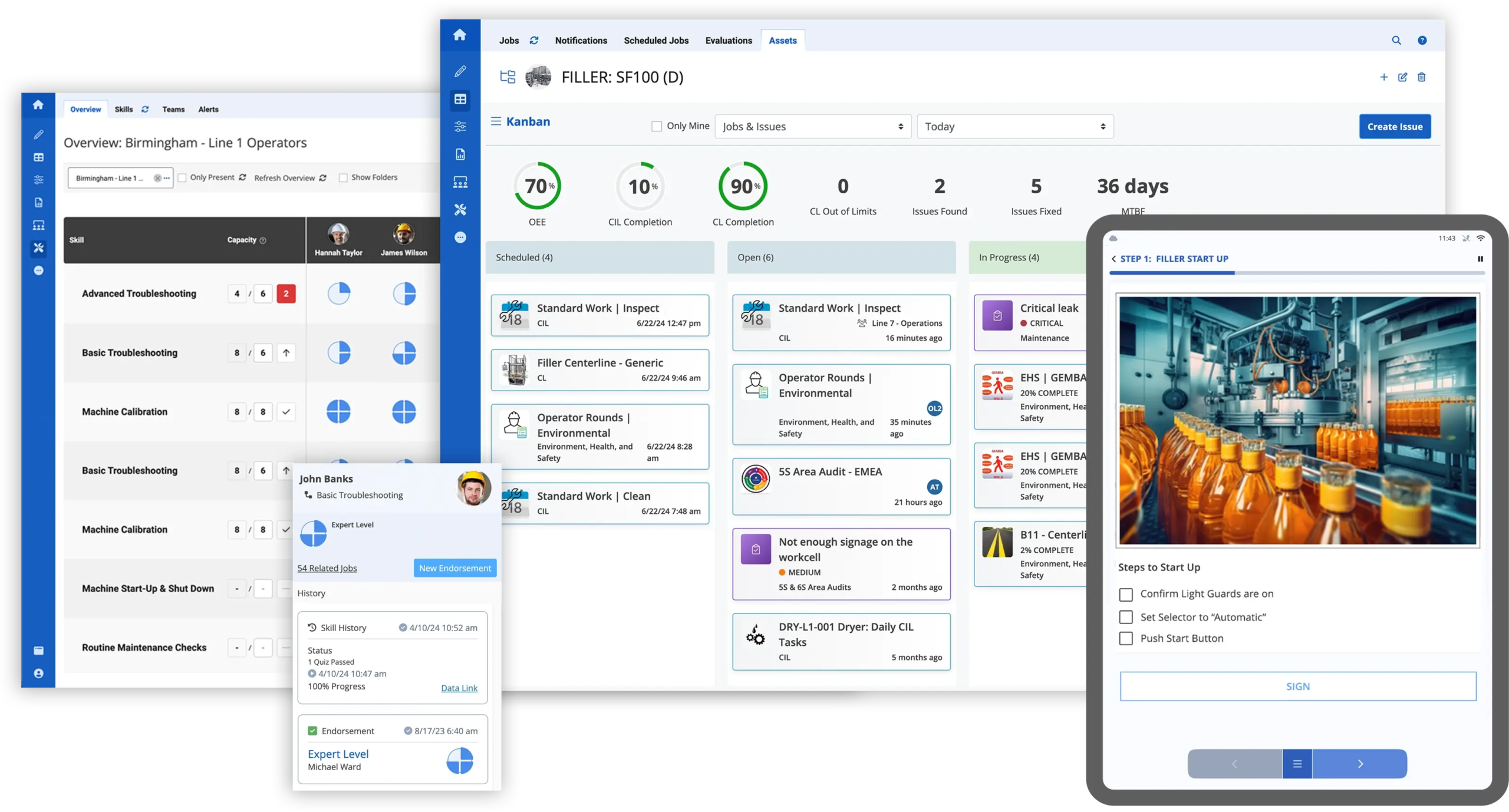

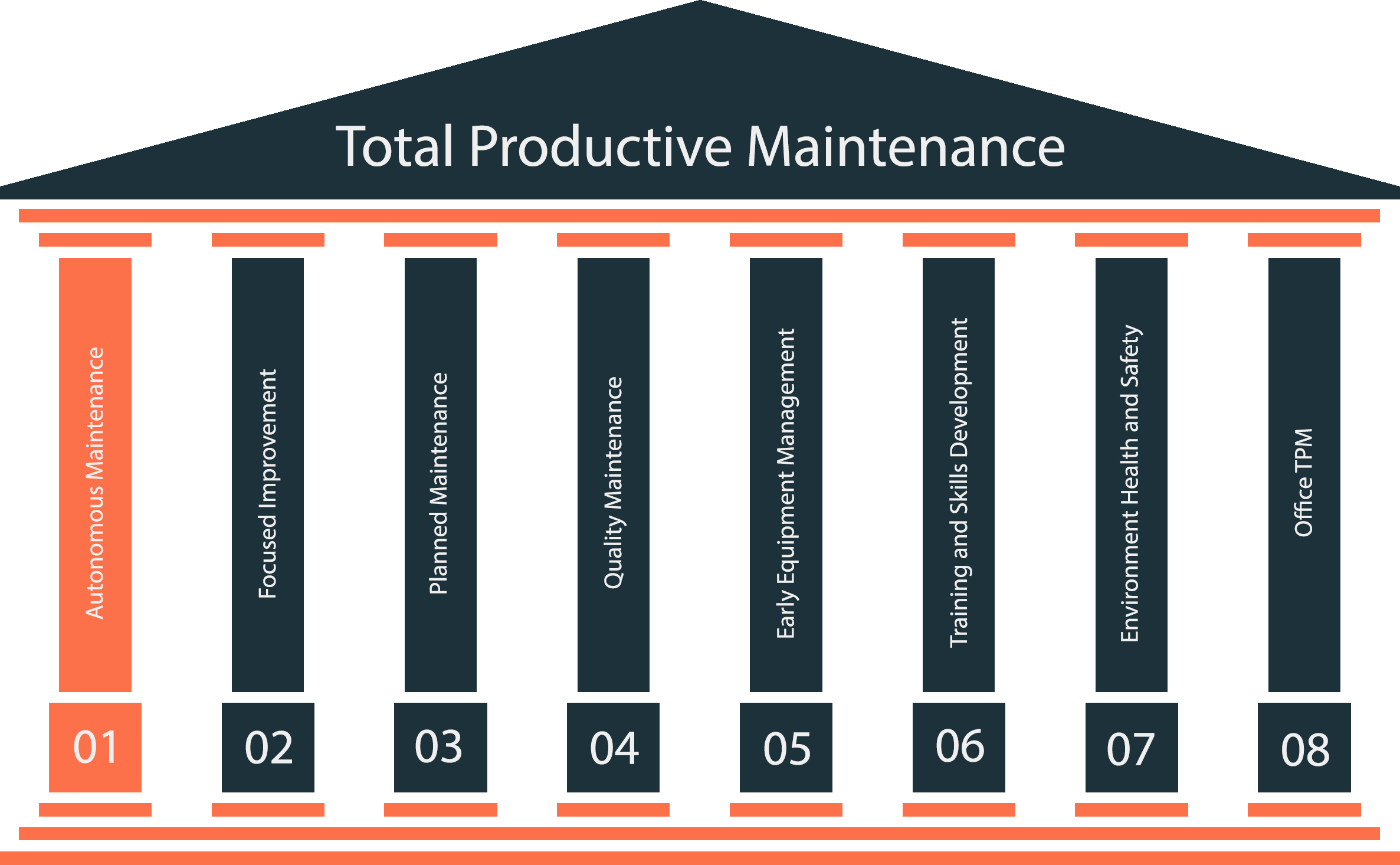

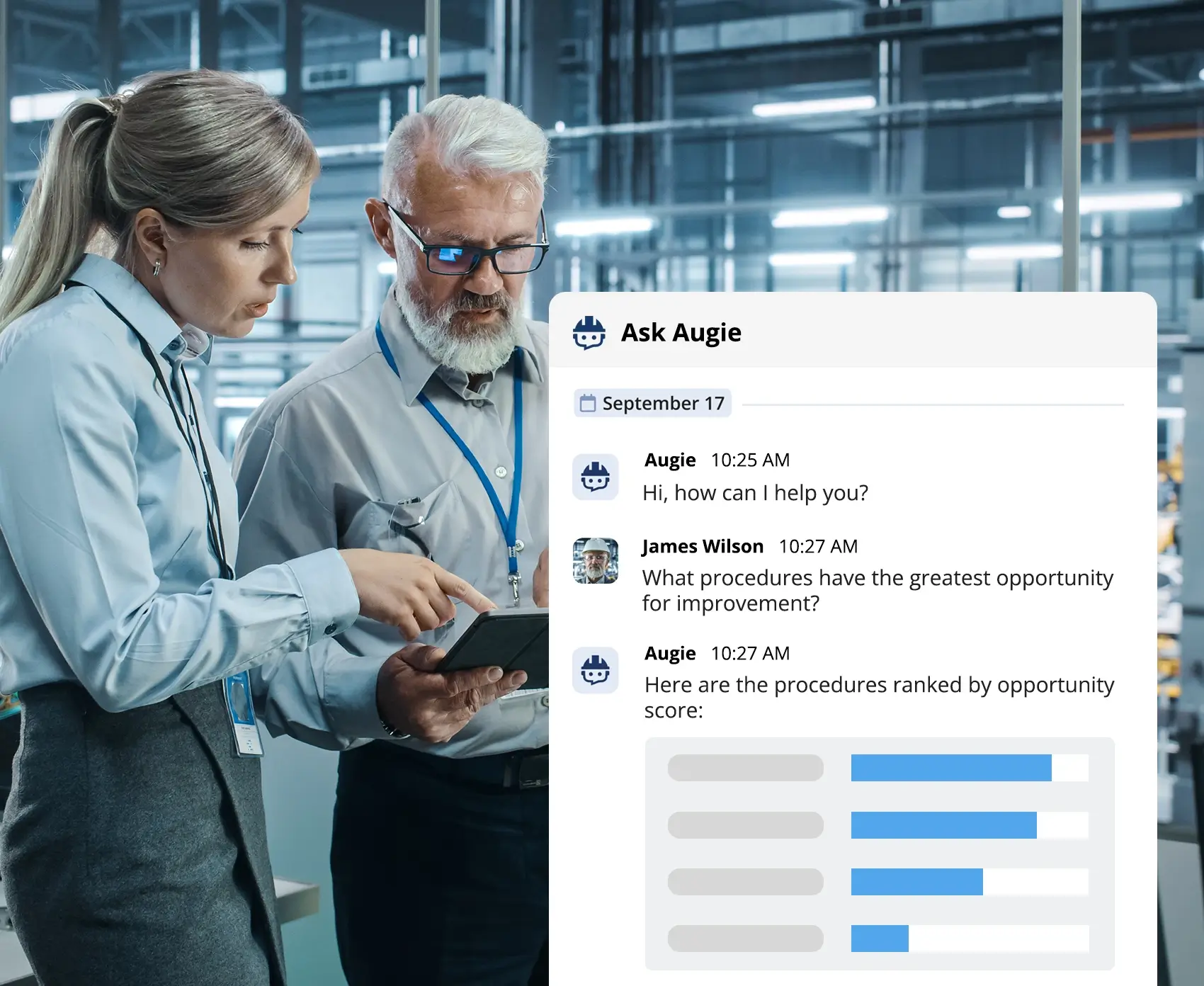

Augie redefines the next phase of AI in manufacturing by seamlessly integrating generative AI into frontline operations to accelerate digitization, as well as enhance productivity and worker empowerment. Augie includes a complete suite of AI-powered assistants and AI services that help bridge the skills gap, accelerate onboarding, and ensure frontline workers are equipped with the knowledge they need to succeed.

The Augie Industrial Gen AI Suite transforms every stage of the Connected Worker Journey.

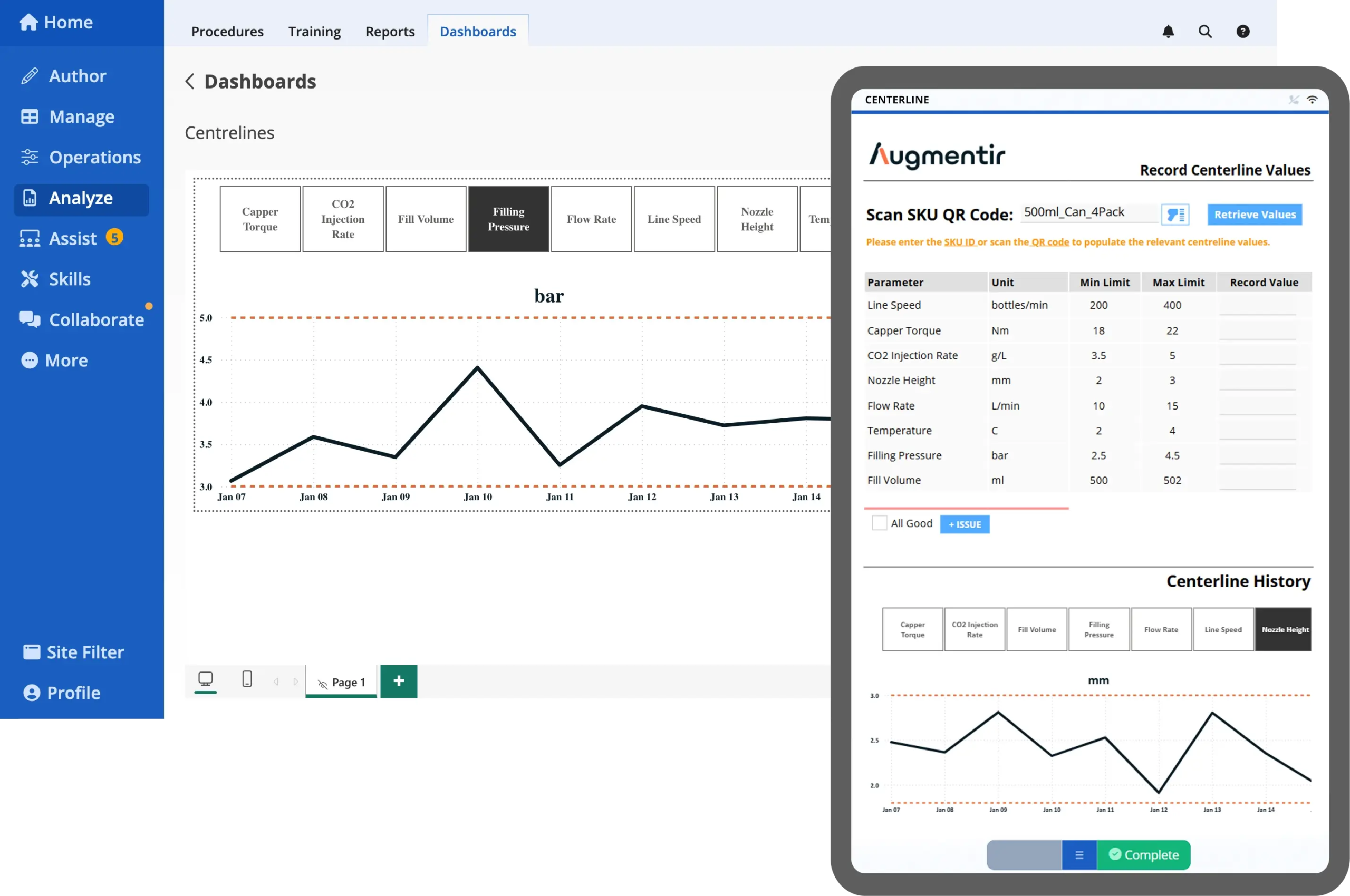

Augie transforms every stage of the connected worker journey by providing a complete suite of AI tools that evolves alongside an organization’s needs. It begins with the digitization of processes and the conversion of static, paper-based content into dynamic, interactive digital workflows, making operations more accessible and efficient for frontline workers. As operations become connected, Augie leverages real-time data to deliver actionable insights, enabling companies to identify inefficiencies, improve workflows, and drive continuous improvement.

Beyond operational enhancements, Augie fosters continuous innovation through its extensibility and seamless integrations with other enterprise systems, creating a unified, scalable ecosystem that adapts to new challenges and opportunities. By addressing every phase of the connected worker journey, Augie empowers organizations to not only modernize their operations but also build a foundation for long-term success and innovation.

Now is the time to embrace the future of manufacturing—don’t miss out on the opportunity to empower your workforce and elevate your operations with Augie. Take the first step toward a smarter, more efficient manufacturing environment today.