In conversations with our customers, a recurring theme emerges when discussing their transition to digital processes: the largest cost and burden often lies in the time and effort required to digitize existing paper-based materials.

Is your manufacturing operation still clinging to outdated paper-based processes? It’s time to face the facts: paper is holding you back. The effort spent managing paper trails, outdated Standard Operating Procedures (SOPs), and inconsistent training materials isn’t just inconvenient—it’s a direct drain on your productivity, efficiency, and bottom line.

Generative AI (GenAI) offers a transformative way to digitize content, automating the conversion of paper-based materials like SOPs, work instructions, and checklists into structured, editable digital formats. It can enhance content by improving clarity, integrating visuals, translating languages, and customizing workflows. This significantly reduces manual effort and accelerates transitions to cost-effective digital systems.

Read below to learn more about the challenges of content digitization, the potential benefits of going paperless, and how Augie, a Generative AI solution from Augmentir, is empowering manufacturing companies to accelerate their digital transformation.

- The Benefits of a Paperless Shop Floor

- Challenges

- Your Paperless Shop Floor with Augie

- Drive Manufacturing Efficiency with a Paperless Shop Floor

The Benefits of a Paperless Shop Floor

A paperless shop floor in manufacturing offers numerous benefits, including enhanced efficiency by eliminating time-consuming manual paperwork and reducing errors. It provides real-time access to digital work instructions, improving accuracy and productivity for frontline workers. Digitization supports better compliance with safety and quality standards while enabling faster updates to workflows.

Additionally, going paperless reduces environmental impact by minimizing waste, aligns with sustainability goals, and fosters a connected, data-driven environment where insights from real-time data can drive continuous improvement and innovation.

Here are the top benefits of going paperless:

- Accelerate employee onboarding: By digitizing onboarding and moving training into the flow of work, manufacturers can reduce new hire onboarding time by 82%.

- Increase productivity: Digitizing manufacturing operations means no more manual, paper-based data collection or record-keeping. Workers have more time to run their equipment, execute shop floor tasks, and find solutions to problems.

- Boost data accuracy: Humans are prone to making mistakes, but digital data capture and validation can help offset human error and improve accuracy.

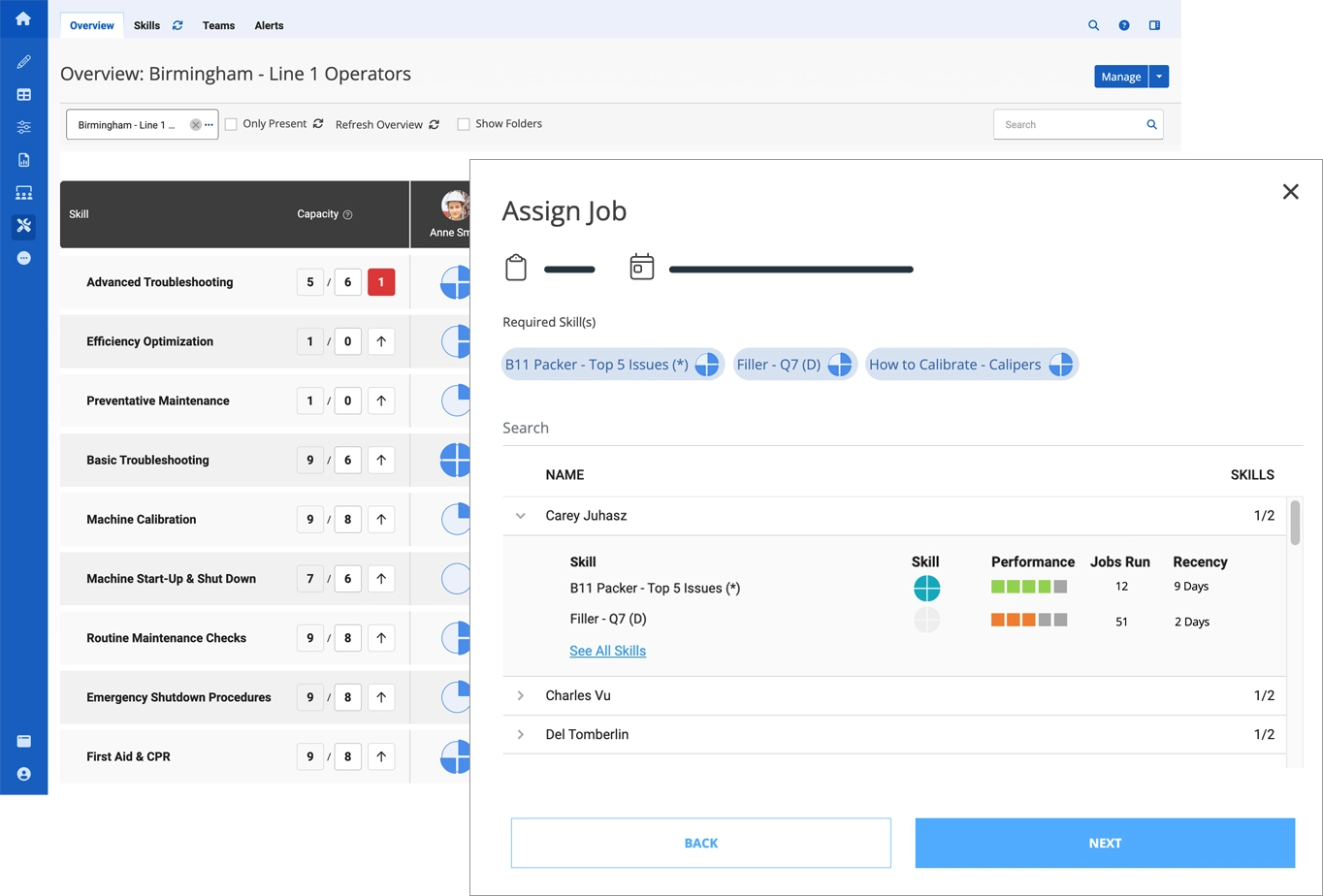

- Improved workforce management: Digital skills tracking and AI-based workforce analytics can help optimize production operations and maximize worker output.

- Manage real-time operations: Human-machine interface systems eliminate the need for paper, files, and job tickets. This means that workers can analyze inventory and other data in real-time.

- Save money, minimize waste: Although going paperless means that the cost of paper is eliminated, the savings extend beyond that. With greater productivity, operations in real-time, and improved production optimization, costs and waste can be reduced in many areas, aligning with corporate sustainability goals.

Challenges

Going paperless in manufacturing isn’t without challenges, and ignoring them can stall your progress.

Standard Operating Procedures (SOPs), work instructions, and checklists are typically built over years, representing a significant repository of organizational knowledge. Converting these into digital formats while maintaining accuracy and accessibility can be daunting. Digitizing years’ worth of SOPs, work instructions, and checklists can feel overwhelming, but staying stuck in outdated systems costs more in the long run. Resistance from workers who are comfortable with paper-based processes can slow adoption, and if your digital tools aren’t intuitive, you risk alienating your team. Integration with existing systems is no small task, and if you’re not prioritizing data security, you’re leaving your operation vulnerable. Overcoming these hurdles is essential to stay competitive.

This is where Generative AI and Augie can provide transformational value.

Generative AI has transformative potential for digitizing content by automating the conversion of paper-based materials into structured, digital formats. It can analyze and extract information from documents like SOPs, work instructions, or checklists, quickly translating them into editable, standardized templates. GenAI also enables content enhancement, such as rewriting for clarity, integrating visuals, language translation, or adapting content for specific workflows. By accelerating the digitization process and reducing manual effort, GenAI empowers organizations to transition to digital systems more efficiently and cost-effectively.

Your Paperless Shop Floor with Augie

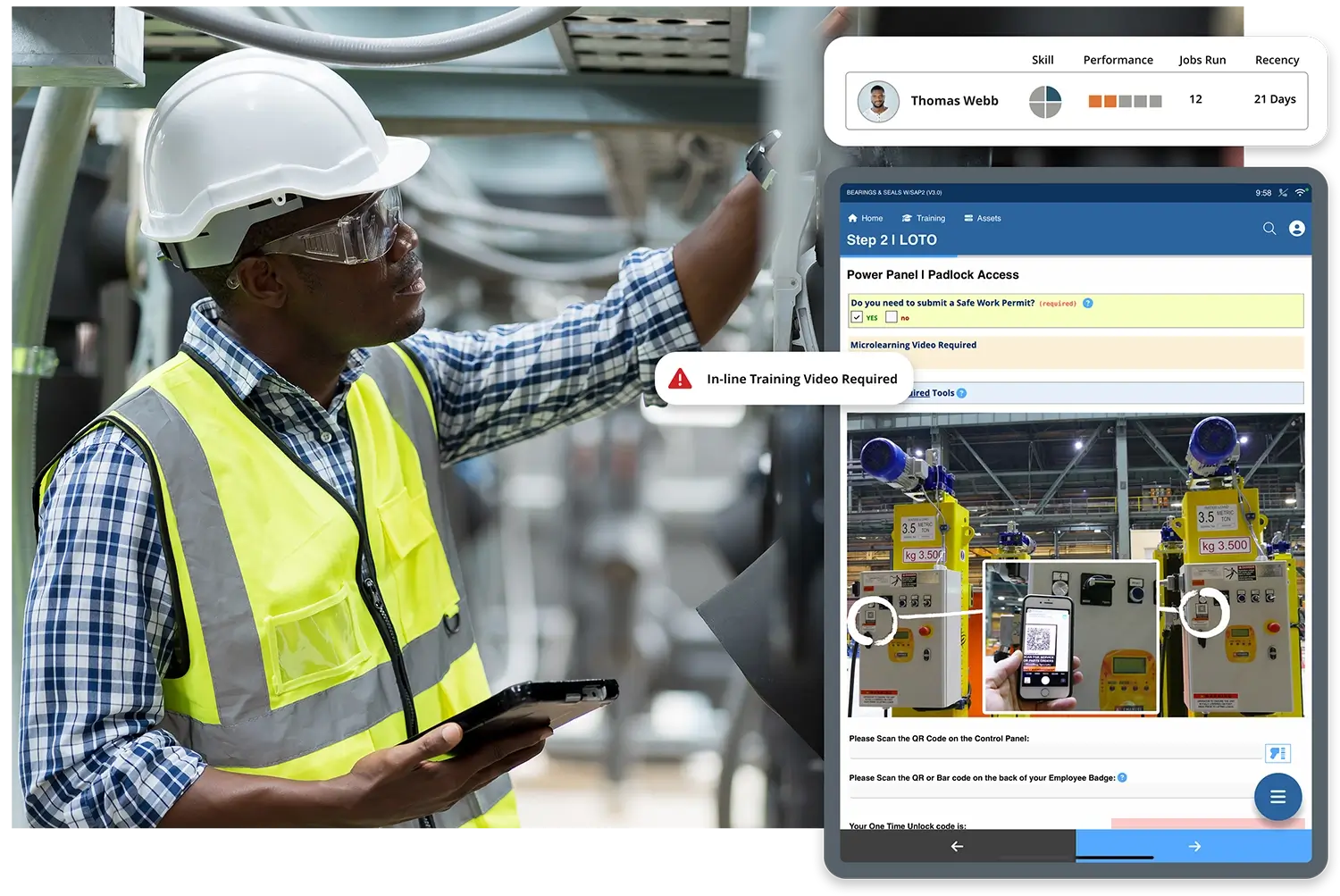

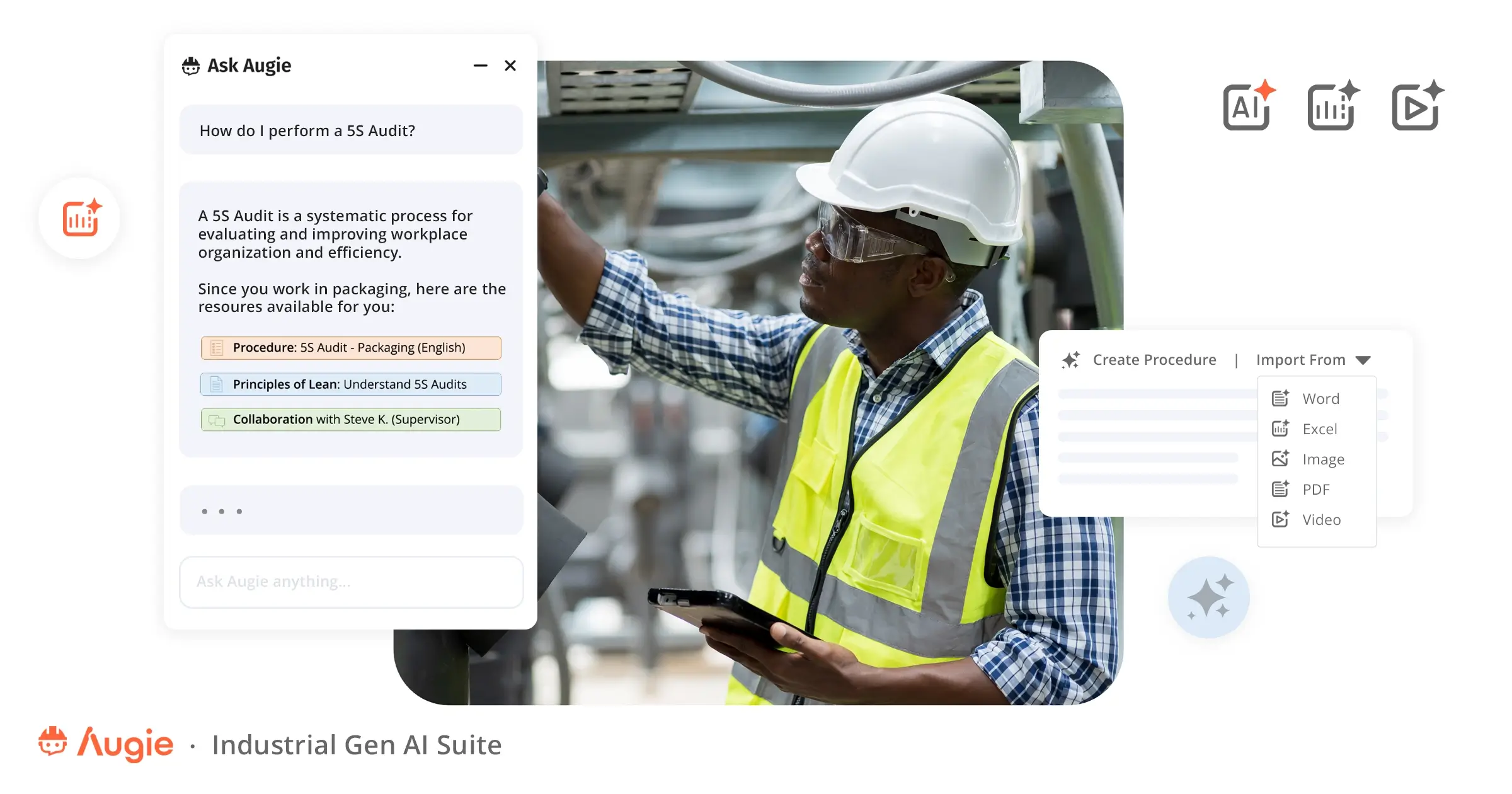

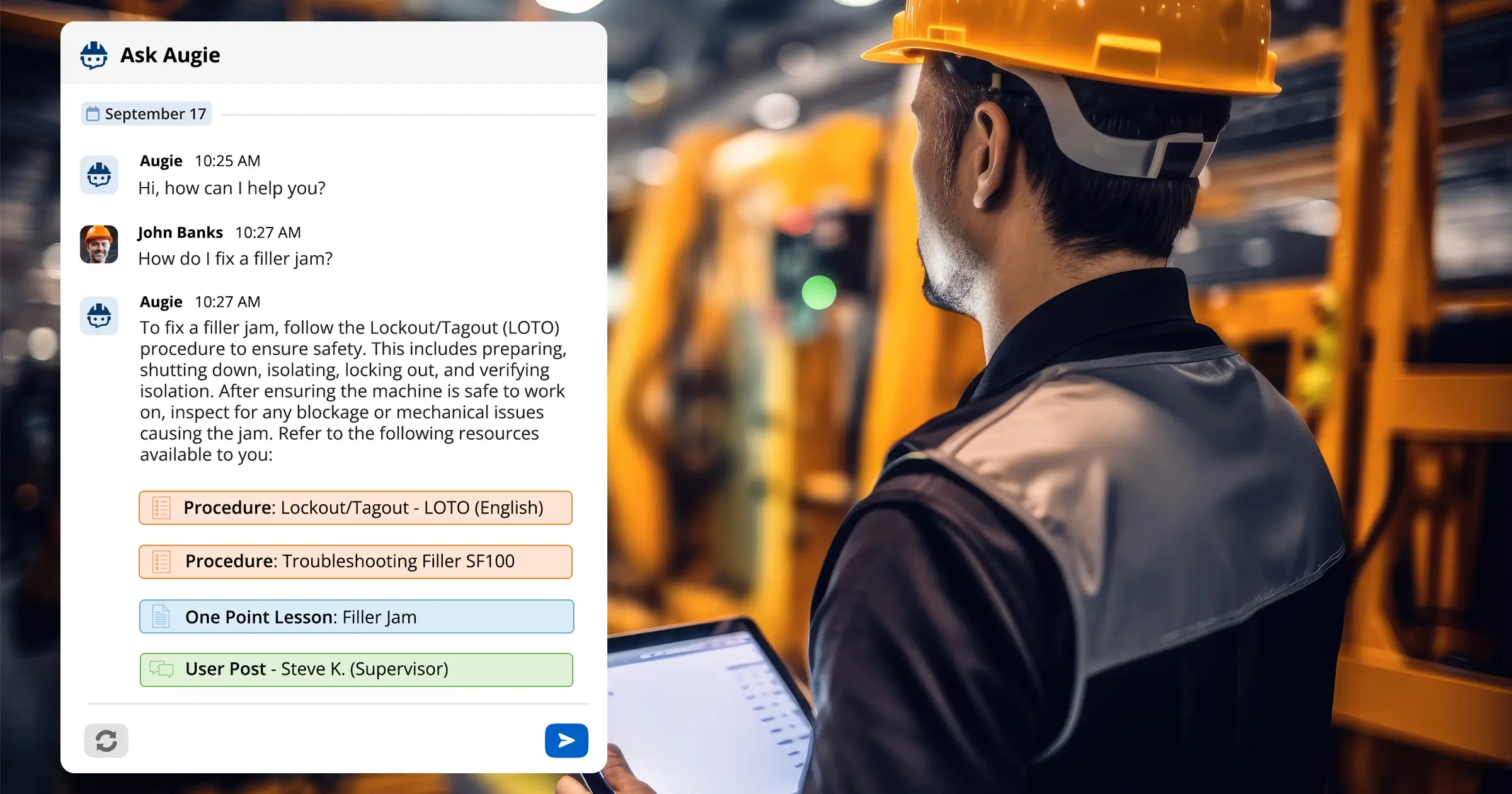

Augie, a suite of Industrial Generative AI tools from Augmentir, revolutionizes industrial digital transformation by combining advanced AI capabilities with practical, human-centric applications. Augie uses generative AI and the power of advanced Large Language Models (LLMs) to transform digital content creation, create adaptive workflows, provide real-time worker guidance, and analyze data to deliver actionable insights.

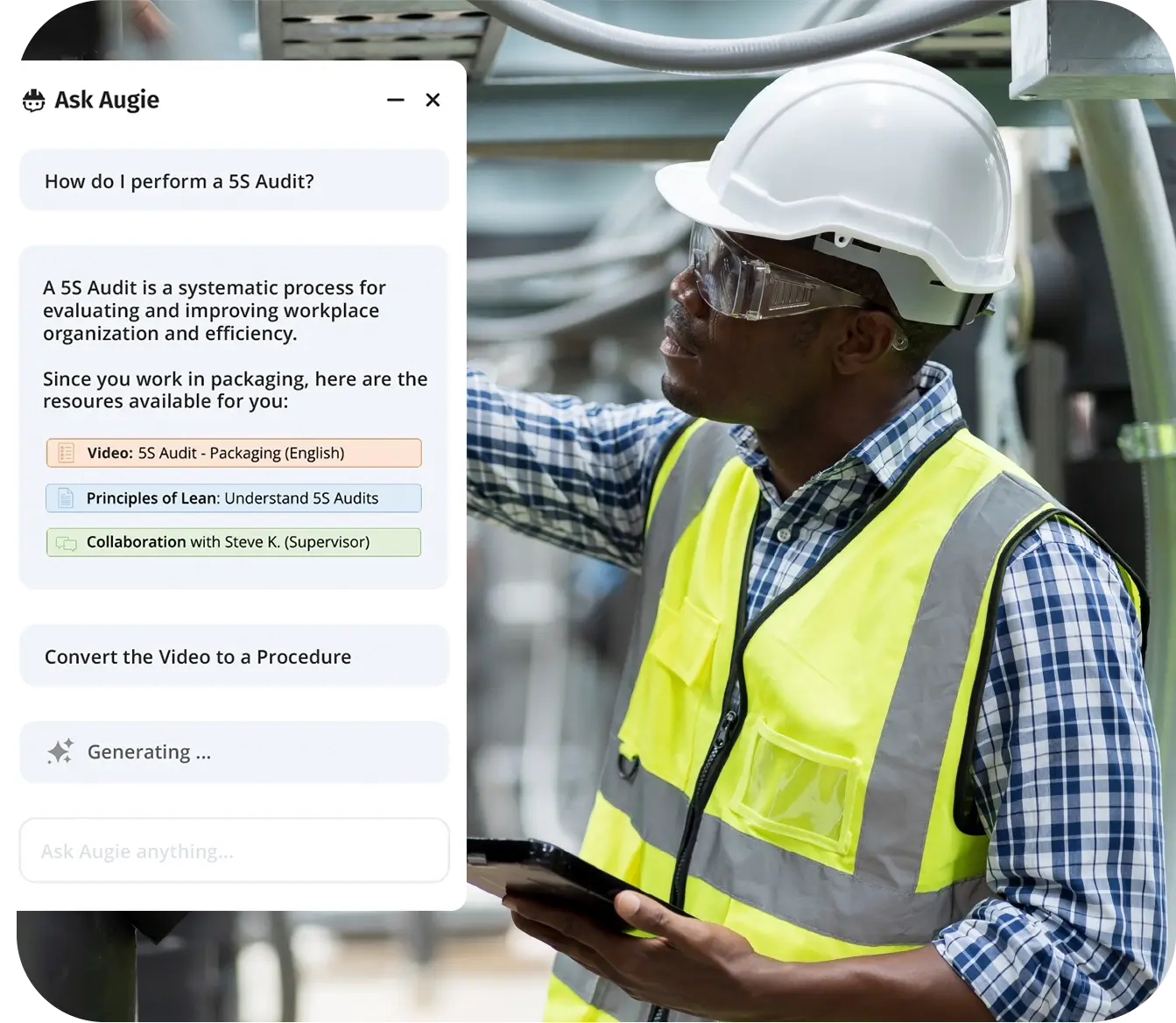

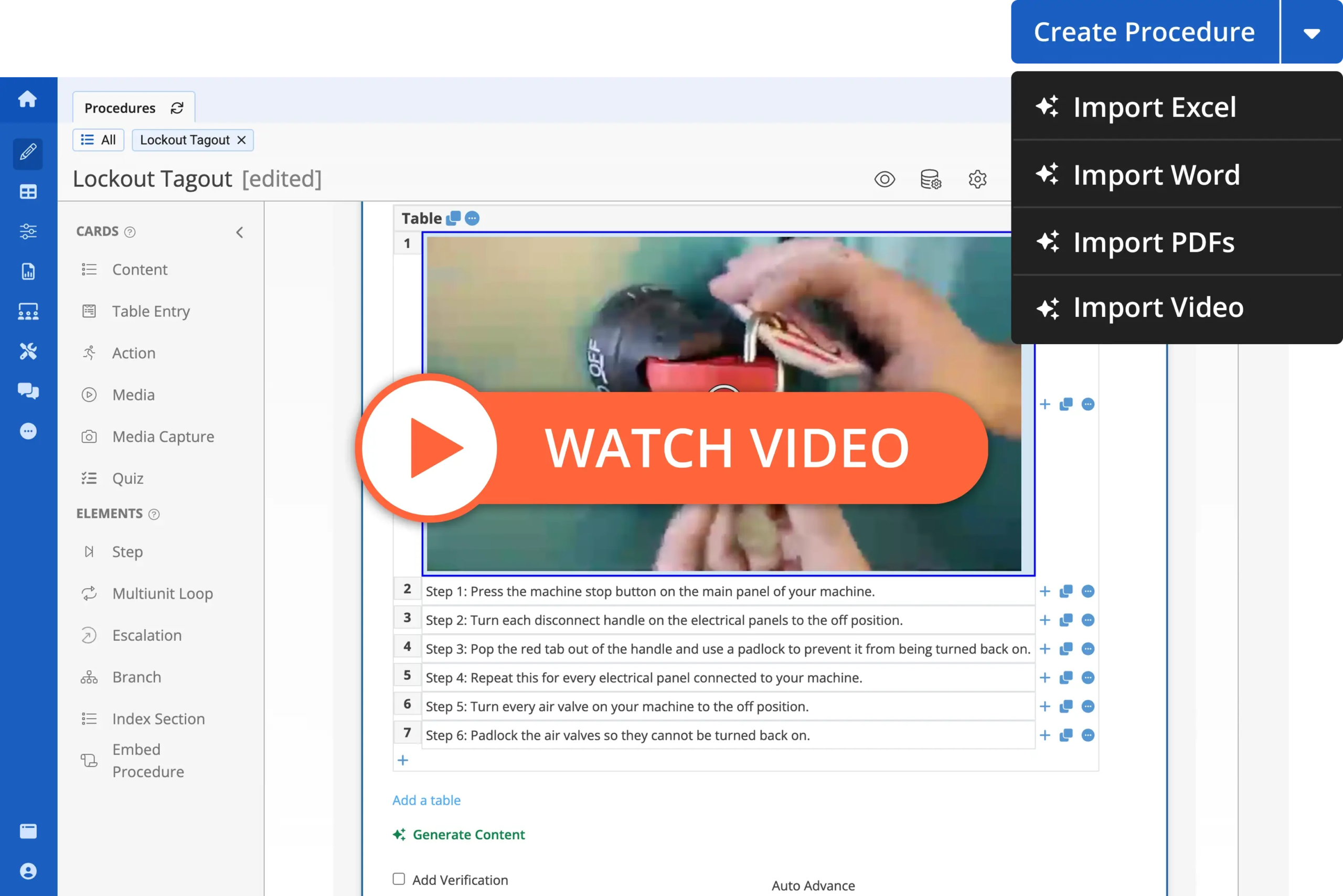

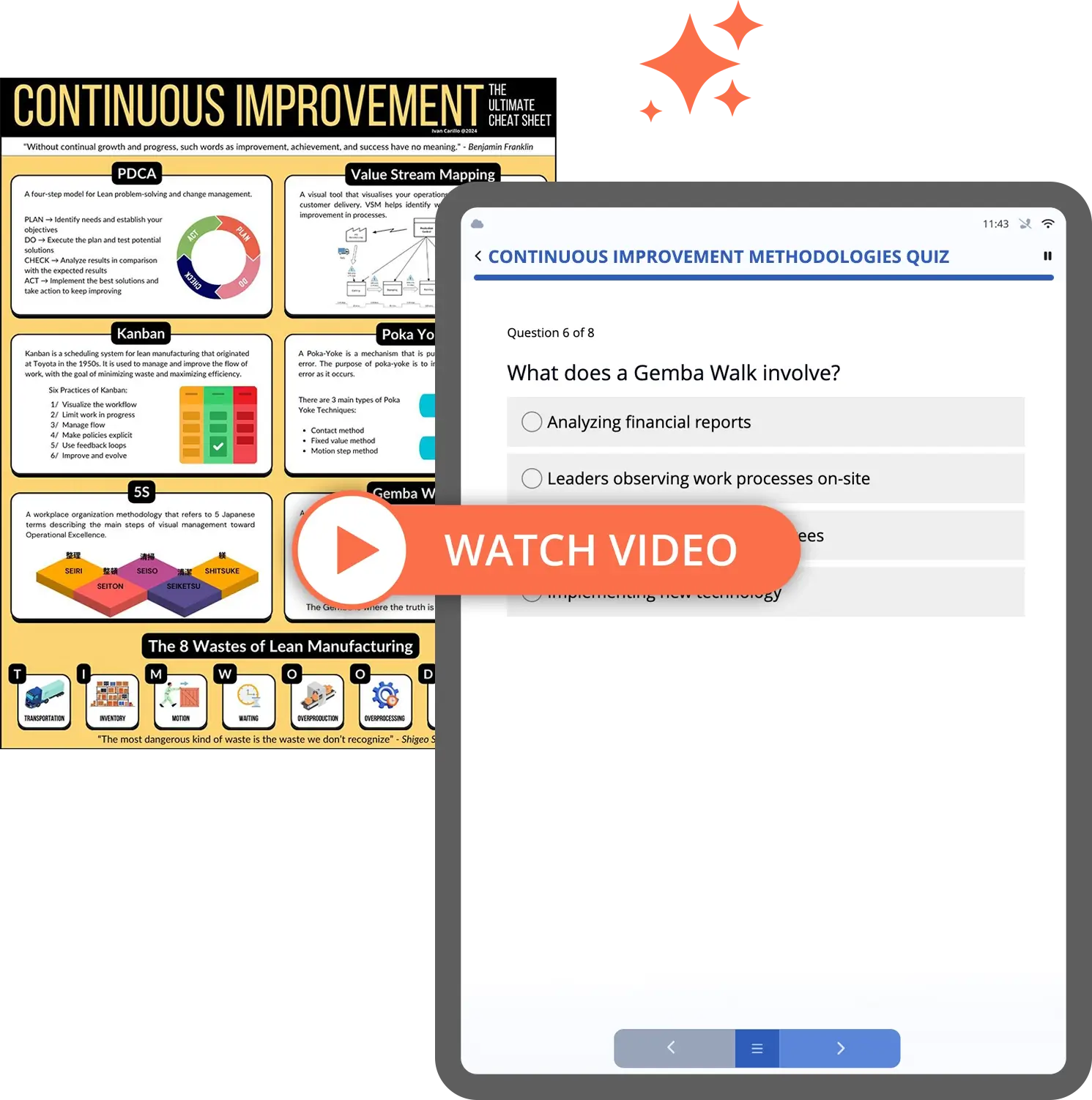

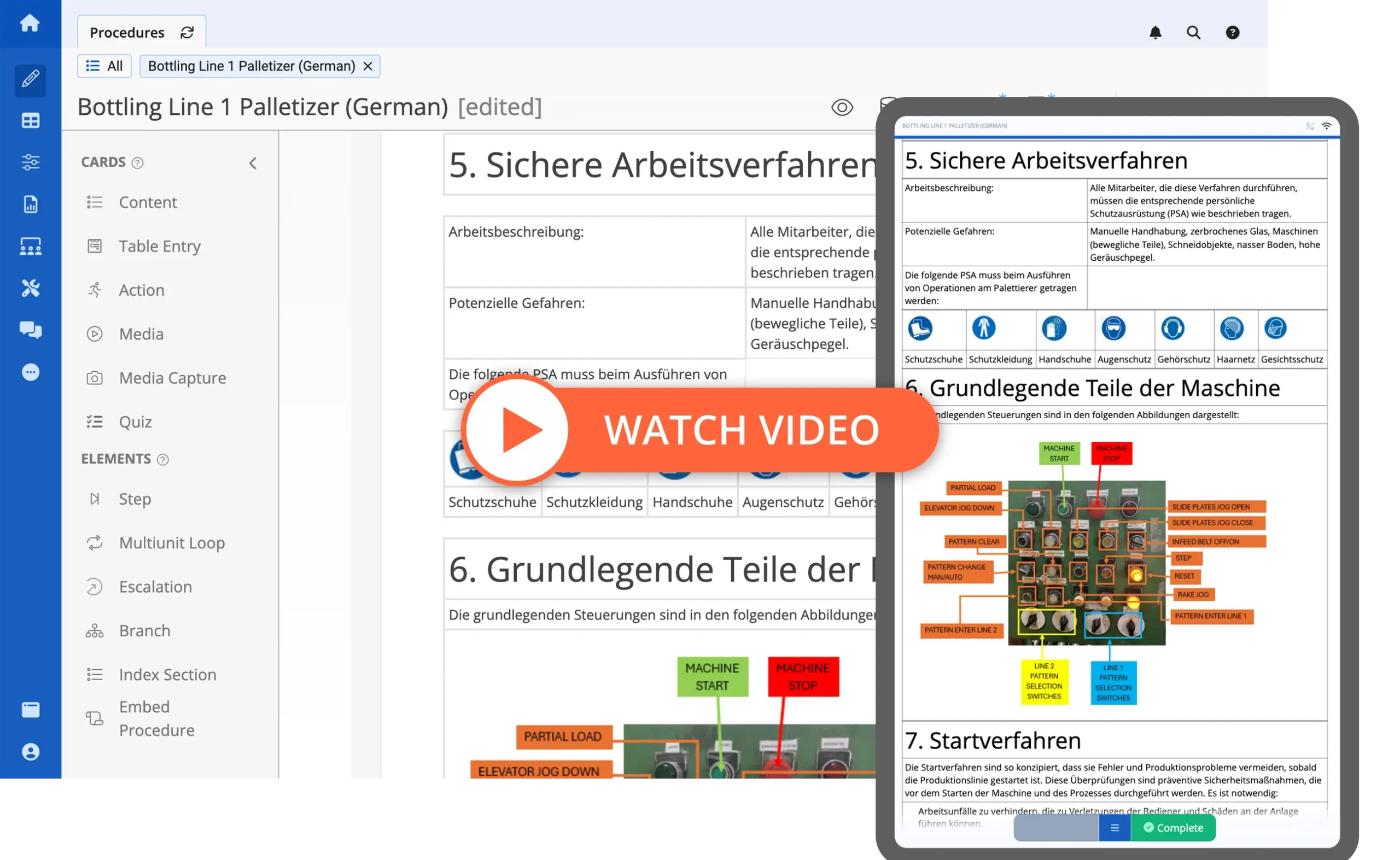

Augie is a powerful tool for accelerating the transition from paper-based to digital operations in manufacturing and industrial settings. Quickly generate standard work procedures from Excel, Word, PDFs, images, or videos. The Augie Content Assistant takes your existing content and generates digital smart forms, checklists, and digital work instructions. Augie automatically analyzes SOPs, work instructions, and other documents to create clear, simplified training modules. It generates interactive quizzes to reinforce key concepts and adapts learning materials to individual skill levels, ensuring workers engage with relevant content.

With Augie, you can move past the inefficiencies of paper-based frontline work. Augie transforms your paper-based workflows into dynamic digital tools in just days, streamlining processes, reducing errors, and equipping your workforce to excel in today’s fast-paced environment.

“

Augie has been instrumental in helping us quickly transform our existing paper-based SOPs and training documents into interactive digital work instructions and learning tools. We’ve reduced our digitization effort from months down to days. This has streamlined our processes, reduced errors, and accelerated the upskilling of our workforce.

Digital Transformation Lead

Fortune 100 Food & Beverage Manufacturer

Digitizing isn’t just an upgrade—it’s a step toward smarter, more competitive operations. Augie optimizes content for frontline workers, provides real-time feedback, and eliminates barriers like language gaps or compliance issues. Paper simply can’t keep up with the actionable insights and adaptability that Augie offers.

Drive Manufacturing Efficiency with a Paperless Shop Floor

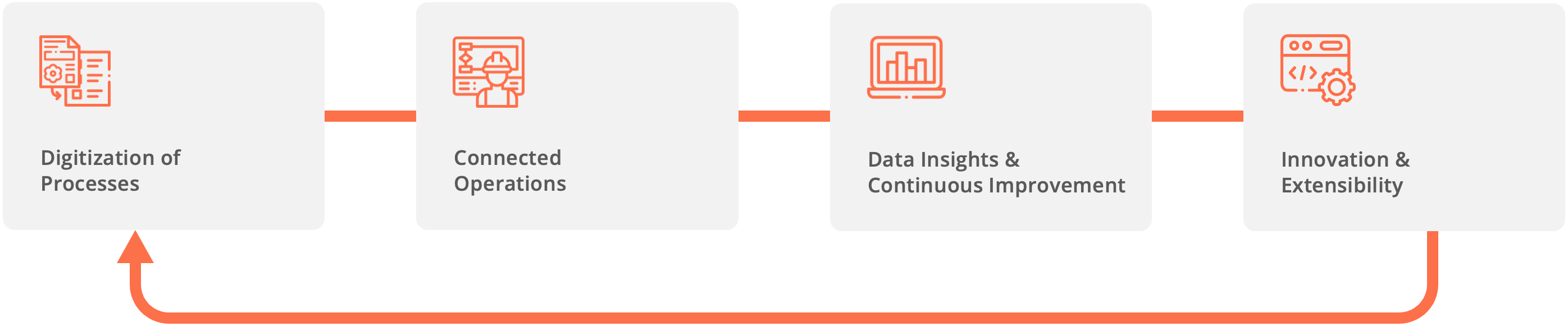

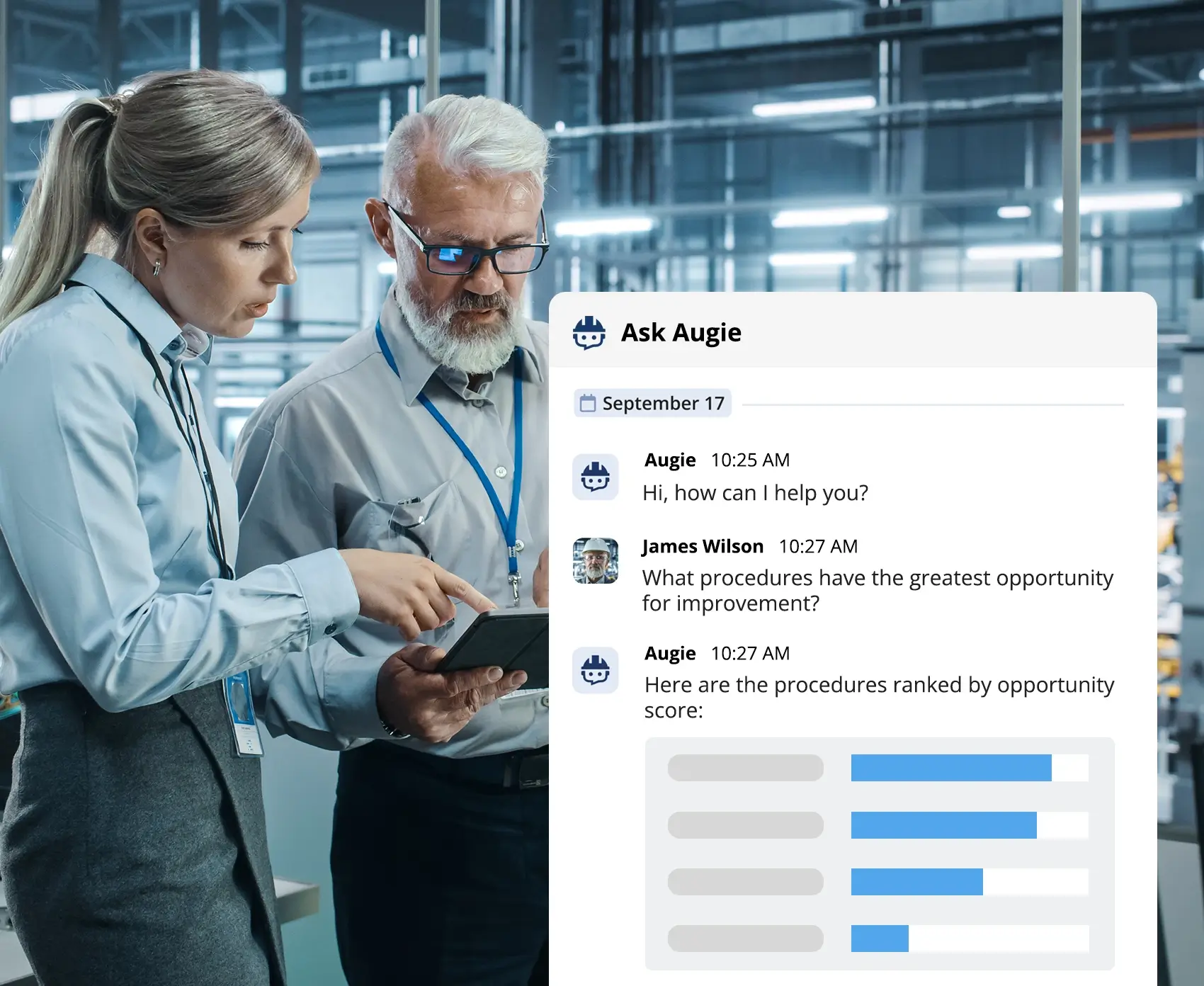

Augie revolutionizes the connected worker journey by offering a robust suite of AI tools that grow alongside organizational needs. It begins by transforming static, paper-based processes into dynamic, interactive workflows, enhancing accessibility and efficiency for frontline workers. As operations become digitally connected, Augie uses real-time data to identify inefficiencies, optimize workflows, and drive continuous improvement.

The Augie Industrial Gen AI Suite transforms every stage of the Connected Worker Journey.

With its seamless integration capabilities, Augie creates a scalable ecosystem, enabling innovation and adaptability. This comprehensive approach empowers organizations to modernize operations and build a foundation for sustained success and growth.

Ready to Learn More?

If you’re ready to modernize and future-proof your operations, Augie is here to help you take the leap into a truly paperless shop floor. If you’re serious about building a resilient, efficient operation, it’s time to stop making excuses and start taking action. Augie isn’t just a tool—it’s the future of manufacturing. Step into a paperless shop floor and see the difference for yourself.