What is Centerlining?

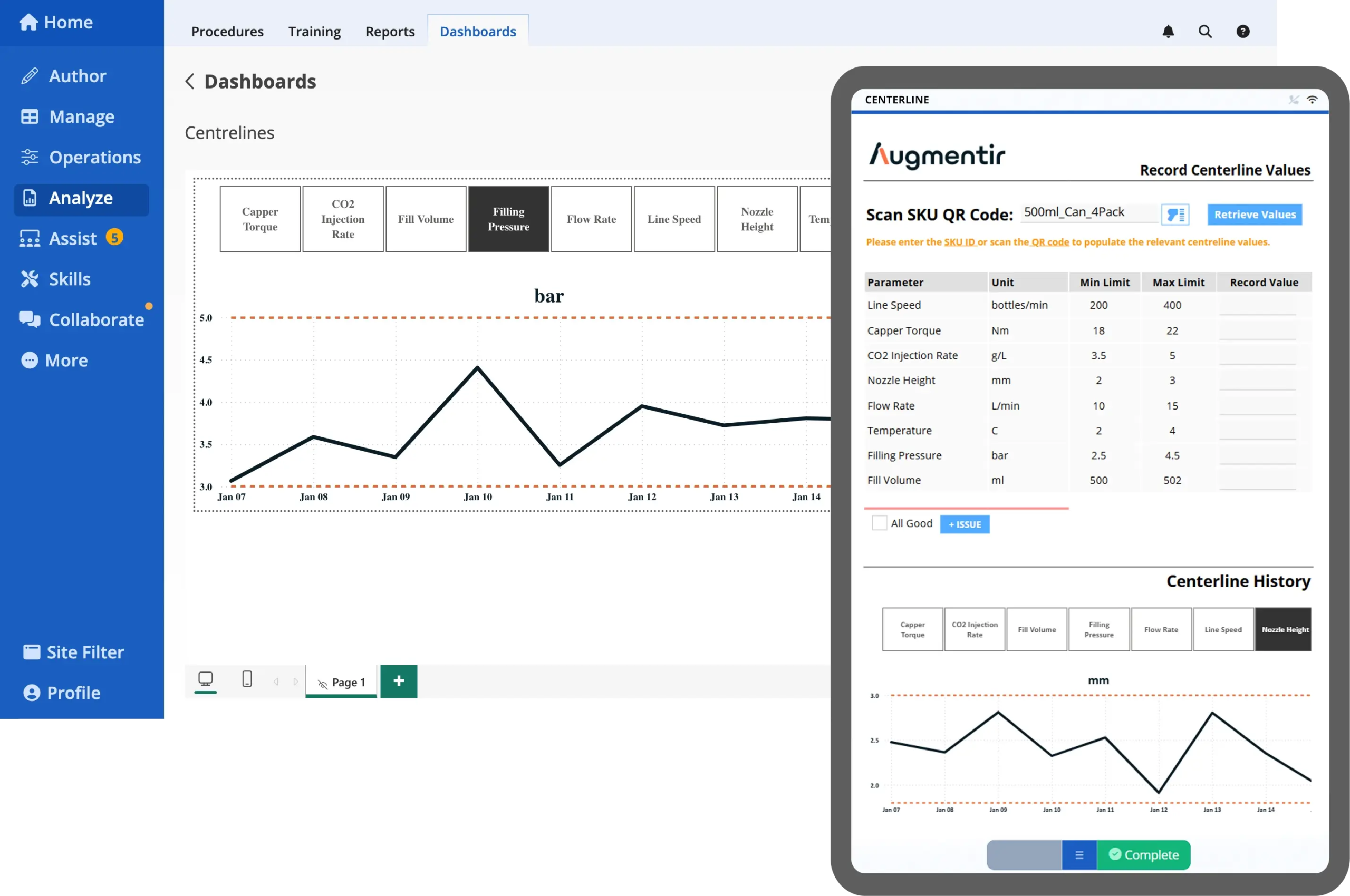

Centerlining is a methodology that focuses on using established process settings to ensure consistent shop floor operations. In manufacturing, it works to decrease product and procedure inconsistencies by optimizing machine effectiveness.

Centerlining serves two primary purposes: 1) identifying which machine settings are needed to best perform a production process and 2) making sure operators implement those settings at all times to prevent product defects.

The type of machine settings that can be centerlined to develop high-quality goods range from speed, temperature, and humidity settings to guard rail alignment and accurate pressure points. Activating the correct equipment settings can help standardize procedures throughout all operations and reduce production waste.

Centerlining works in tandem with total productive maintenance (TPM), a widely used methodology for enabling workers, equipment, and supporting processes to preserve and enhance the safety, quality, and integrity of production in manufacturing.

Learn more about centerlining, its relationship with TPM, and its benefits by exploring the following questions: