Augmentir’s AI-powered connected worker solution highlighted as Most Complete Product in new report from LNS Research.

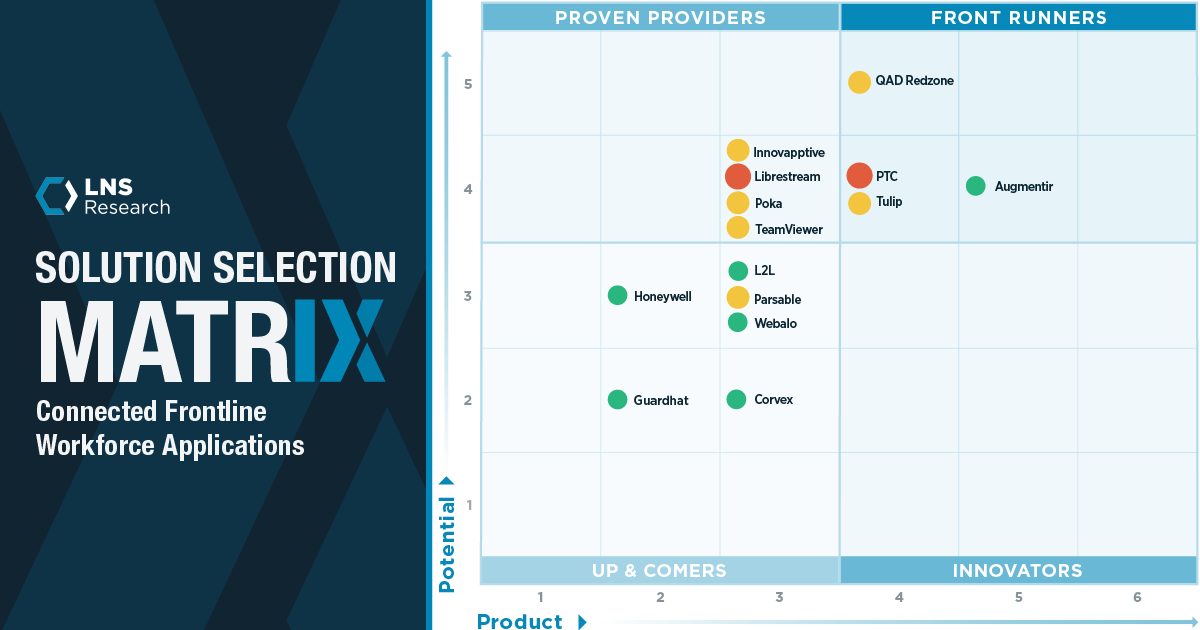

August 22, 2023 – Augmentir, provider of the world’s leading connected worker solution, announced today that it has been named a Front Runner within the 2023 LNS Research Connected Frontline Workforce Applications Solution Selection Matrix (SSM).

LNS Research, a leading research and advisory firm focused on empowering industrial organizations, evaluated 14 key vendors within the ever-important and rapidly evolving Connected Frontline Workforce (CFW) environment. LNS Research’s data shows that 72% of industrial organizations are reporting that frontline workforce hiring, onboarding, and retention issues have negatively impacted operational performance.

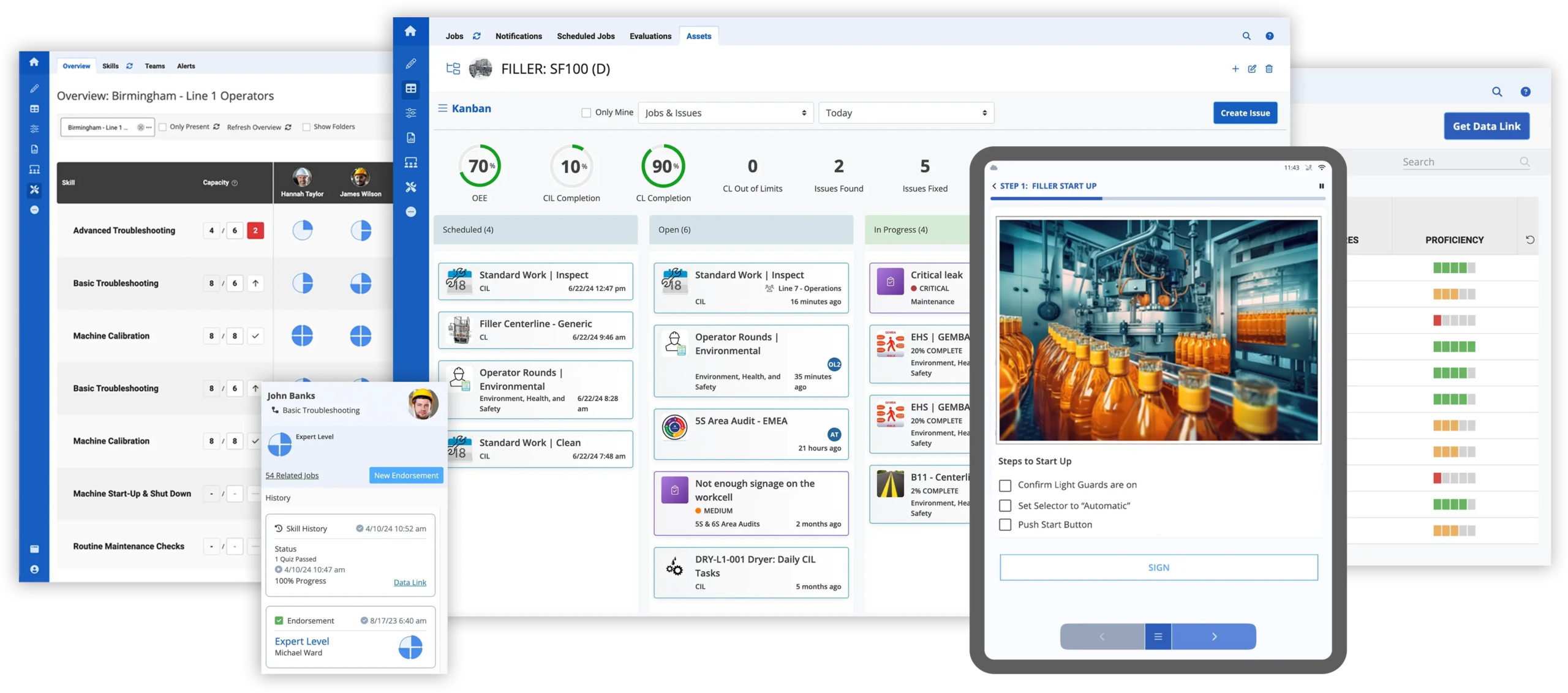

According to LNS Research, “Augmentir offers a CFW application suite with among the most comprehensive capabilities among the vendors included in this research. Its innovative incorporation of AI-based advanced analytics enables data-driven improvement of work processes, individual and team performance and learning, and overall operational performance.” Augmentir was recognized by LNS Research as a market leader for its category-leading product innovation and comprehensive product capabilities.

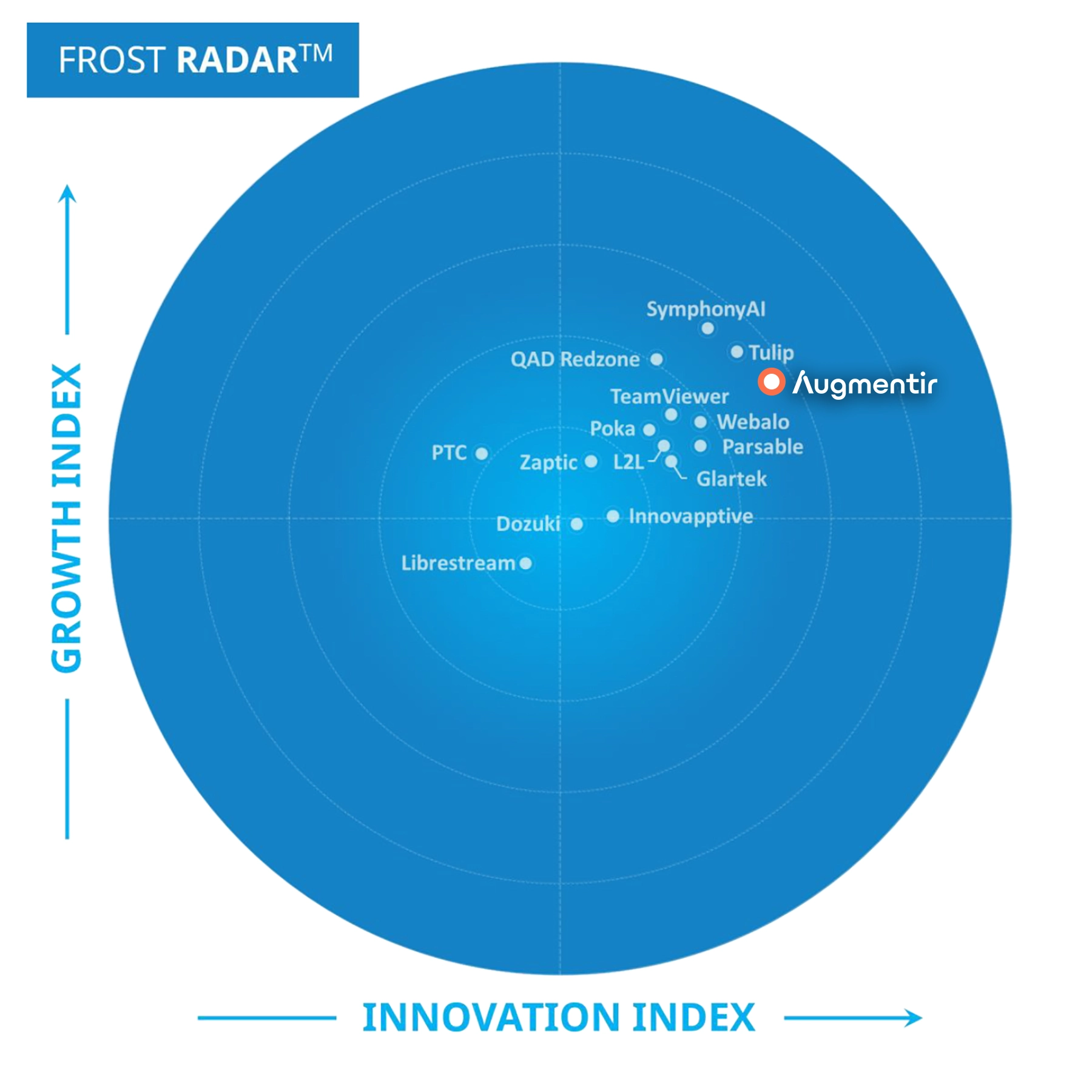

This announcement adds to a growing set of accolades highlighting Augmentir as the market-leading solution in the connected worker space, the company was recently named 2023 “Connected Worker Company of the Year” by Frost & Sullivan, as well as previously being named “Cool Vendor” for Manufacturing Operations by Gartner.

LNS Research further states that: “Augmentir is well-positioned for future growth, with a trajectory that gives it the potential to be among a small set of likely market leaders in the CFW Applications space. This assessment is based on the strength of differentiated capabilities of its AI-enabled solution suite to enable proactive, data-driven performance improvement, personalization of work execution support and training, and the integration of individual and team skills and qualifications to guide workforce development and shift-specific work assignment.”

“The manufacturing industry continues to suffer from a growing labor shortage and overall workforce crisis,” said Russ Fadel, CEO of Augmentir. “This is creating a growing need for more efficient onboarding and worker training, as well as on-the-job guidance so manufacturers can meet production targets with a smaller, less experienced workforce. This latest study from LNS Research highlights this need and how connected worker solutions are central to the solution. We are proud to be at the forefront of this paradigmatic transformation and for this recognition of our innovative, industry-leading solution.”

Download a complimentary copy of LNS Research’s SSM Vendor Profile of Augmentir’s Smart Connected Worker solution to learn why the company is deemed a Front Runner in this critical space.

Important Note: All entries in the Connected Frontline Workforce Applications Solution Selection Matrix represent the opinions of the authors based on their industry experience and their view of the information collected using the methods described in the LNS Research Integrity Policy. LNS Research and the Solution Selection Matrix are trademarks of LNS Research.

About Augmentir

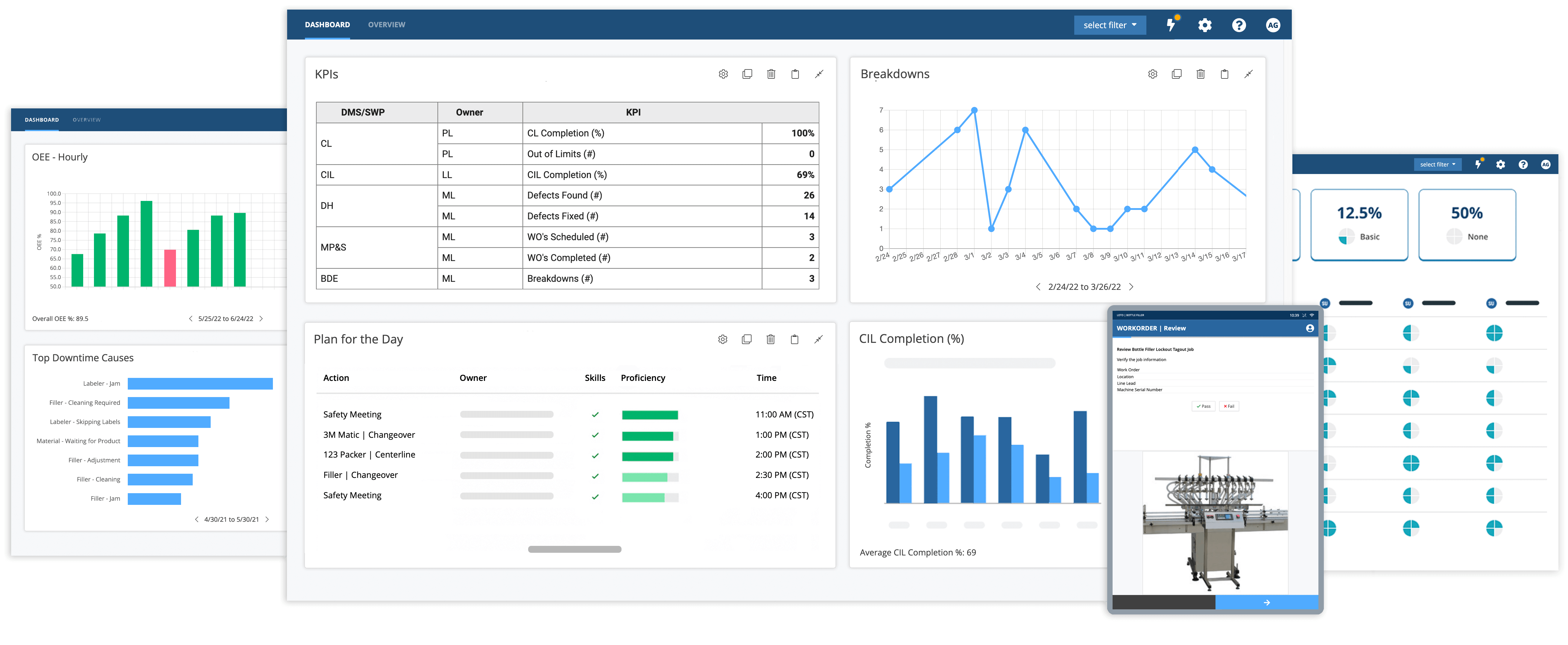

Augmentir™ is the world’s only Smart Connected Worker solution. Augmentir’s software includes a complete suite of connected worker capabilities, connectors to business systems, and broad extensibility that enable manufacturers to digitize their frontline operations, reduce onboarding time, and increase workforce productivity. Companies in manufacturing, service, energy, and construction leverage Augmentir’s suite of tools to deliver effective skills management, training, digital workflow, and collaboration for today’s more dynamic industrial workforce. For more information, please visit www.augmentir.com.