AI-powered technology may be the missing puzzle piece for today’s workforce crisis.

It wouldn’t be fair to attribute all of manufacturing’s current labor shortage woes to the pandemic–there are a lot of factors contributing to this frustrating situation, and many of them were looming long before we ever heard of COVID-19. Did it make things worse? Probably. And the forecast doesn’t look very sunny if you believe what analysts have to say about it. However, despite the current crisis, there is hope yet for manufacturing, specifically in the form of AI and Connected Worker Technology.

Sure, the face of the workforce has changed dramatically. The pool of potential laborers has shrunk. Businesses are being forced to hire people traditionally considered under-qualified. And that leads to a whole host of other complications, including a drop in operational efficiency, a rise in safety issues, and more. The pessimists out there would only see the threat to the global market these challenges pose–the manufacturing industry makes between 11 and 12 percent of the US economy after all.

Good thing we’re optimists at heart! Behind every challenge is an opportunity, as far as we’re concerned. And when it comes to this challenging labor market in particular, we see a huge opportunity for businesses to work with what they’ve got, and still reach operational goals. We have the potential to assess how every worker performs on the job, regardless of the experience and skill set they bring on day one, and use that information to improve individual and enterprise-wide performance. Puts a new light on the labor shortage, doesn’t it?

You can’t fix what you can’t see.

We know using data is important to directing and improving operations–that’s business best practices 101. But insights drawn are only as good as the data itself. And even though there can’t be many businesses out there who haven’t yet jumped on the digital transformation bandwagon, we suspect a lot still rely on outdated data collecting and reporting mechanisms. Those digital spreadsheets had their moment, but we’ve got better options now. Maybe you opted for a Bluetooth software program or distributing a digital survey for your workers. But even with those innovations, what do these data indicators really tell you? Is this reliable and usable information? We didn’t think so either.

Imagine what you could do with real-time data, rather than a summary of operational KPIs at the end of set periods? Even better–imagine capturing the performance metrics of each individual worker rather than their self-generated assessments and observations and having the potential to use that knowledge to improve their skill set and operational proficiency. That’s when data becomes intelligence. And that intelligence has the potential to become so valuable to your enterprise that you’ll wonder how you ever operated without it.

Not convinced you could benefit from data at that level of individual performance? Let us draw an analogy we think you’ll appreciate.

Think of each worker as a newly licensed driver; what happens after passing the road test?

Remember the day you got your driver’s license? We spent hours, if not days and weeks practicing behind the wheel, eagerly waiting to be evaluated by a driving instructor. And let’s be honest, plenty of us winged it, too. Either way, once you show them you can do a three-point-turn and know to stop at the flashing pedestrian crossing sign, everyone walks away with the proof of their proficiency–a driver’s license.

Then what happened? Nothing. Maybe a celebratory high-five and then eventually years of driving. In one, five, or ten years, what do we know about each person’s capabilities? Unless they’ve wracked up a stack of tickets for traffic violations, we don’t know anything. For all we know, they haven’t sat behind the steering wheel since passing. There is no mechanism to re-assess whether drivers are highly skilled or at-risk of creating an accident in operations.

Now what if we looked at our frontline workers through that lens? You know when they were hired that they could perform X, Y and Z. Some could do even more. But what about after that? What if you could assign an AI-based driver instructor to follow each new driver around for ongoing assessment and intervention in the moment of need?

Put smart connected worker technology in the passenger seat

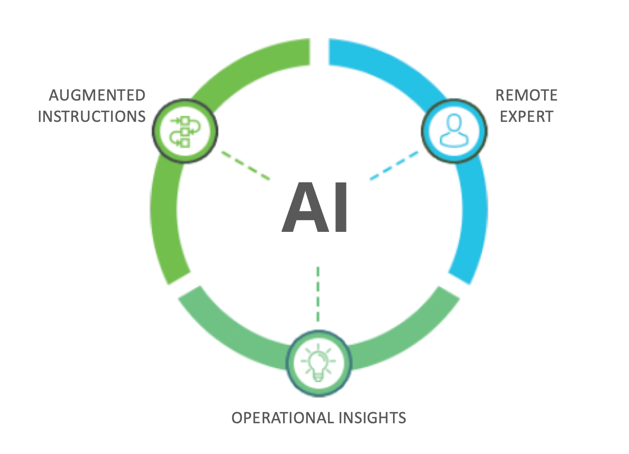

Adopting connected worker technology powered by artificial intelligence (AI) increases the reliability and credibility of data by analyzing employee performance in ‘real-time.’ That individualized data can be used to connect workers with a company’s digital library of training tools and resources, having an immediate impact on operational proficiency and cultivating a healthy learning environment for workers.

Connected worker technology that leverages AI offers self-guided learning processes when opportunities are identified, reduces human error and improves safety, provides updates on pressing issues and equipment failures and access to a variety of applications. Who wouldn’t want to work for an organization like this? One that offers a high probability of job satisfaction and encourages personal skill development? A culture like that can help the operation on many levels, from reducing operational costs to attracting new employees.

What now? There is only one connected worker solution that can provide this level of intelligence on your workforce–contact us to learn more about how Augmentir can benefit your business and ask for a demo!