Learn how to digitize quality assurance, its benefits, and how digital inspection procedures reduce errors in manufacturing.

Quality assurance (QA) and inspection procedures work hand in hand to ensure customers receive quality products free of deficiencies. But what do the terms mean exactly?

QA is a systematic process that manufacturers use to ensure that a product or service meets the requirements for distribution. QA inspections are a subset of that process, checking products before they go off the line. Inspections are a crucial part in troubleshooting and fixing product defects, making improvements, and maintaining compliance.

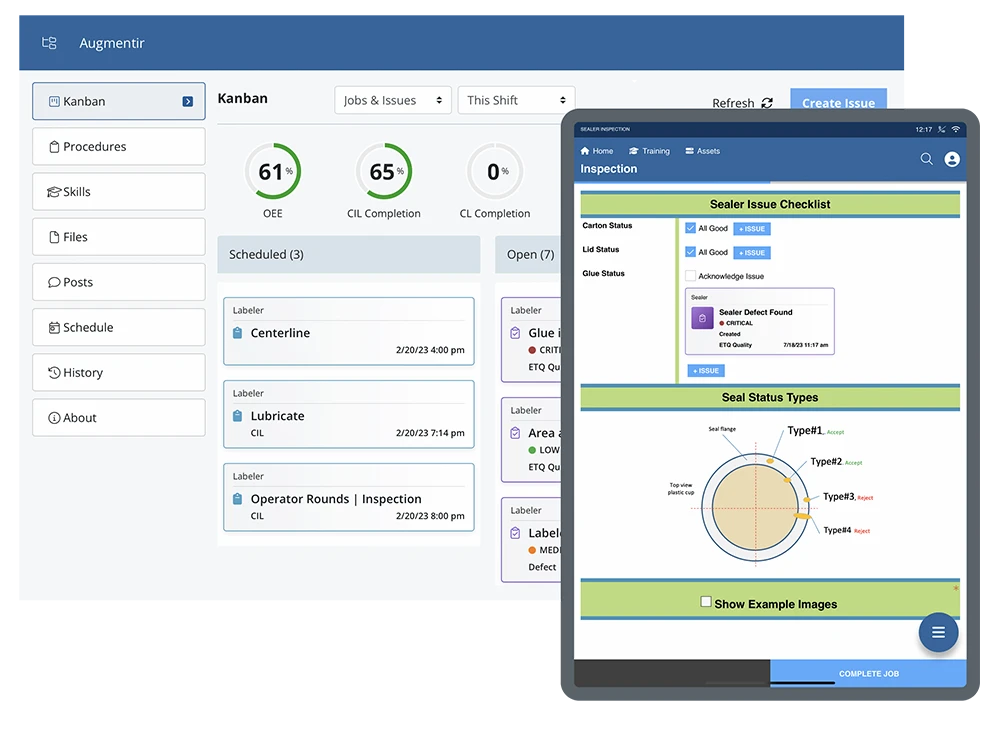

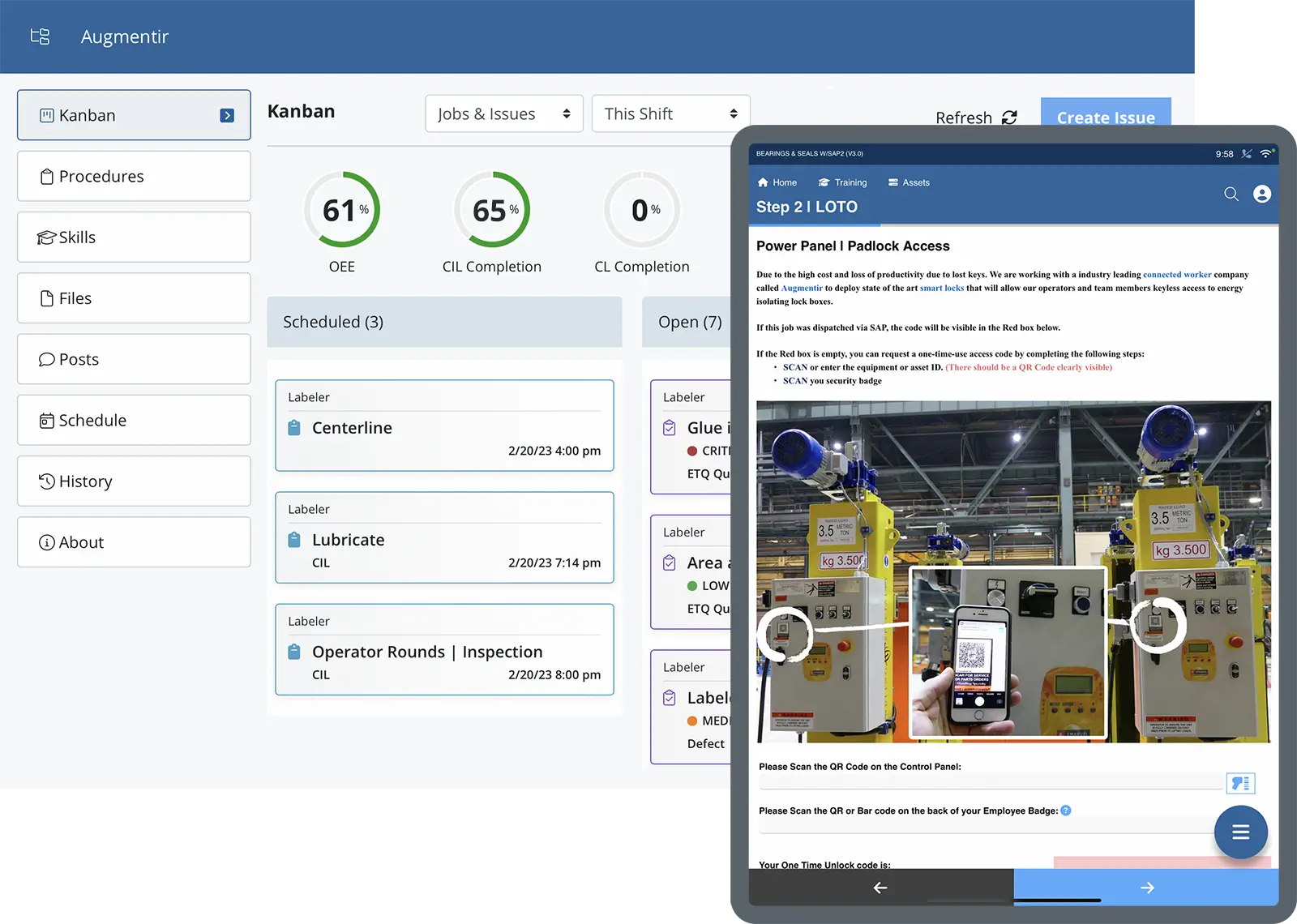

These inspection procedures should be standardized and digitized to create a quality assurance system that ensures workers have access to the correct procedures and that tasks are performed in a standard manner to avoid errors on the production floor. This results in reduced defects, optimizes quality data collection, and decreases the need for rework.

Explore the following topics to learn how to decrease mistakes on the shop floor when you digitize and standardize quality assurance procedures:

- Standardization and digitization explained

- How standardizing QA and inspection procedures reduces errors

- How digitizing quality assurance procedures minimizes mistakes

Standardization and digitization explained

Standardization and digitization work in tandem. Let’s break down the two concepts to get a better idea of how they work.

Standardizing means developing a set of rules for how tasks should be completed. It boils down to this: When you standardize tasks, you’re giving your employees an established, time-tested process to use.

When done right, standardization decreases ambiguity, enhances productivity, boosts quality, and increases worker morale.

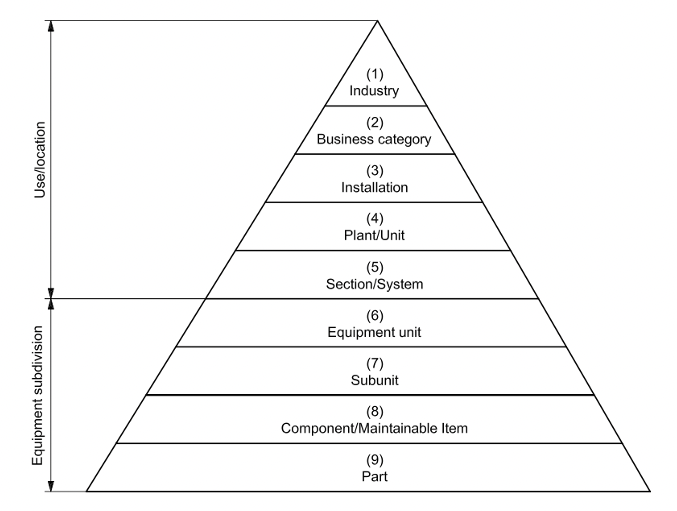

Digitization, on the other hand, involves converting information into a digital format. Keep in mind that it’s the information you are digitizing, not the processes or procedures. Automating your work processes using a single system, like a connected worker platform, makes everyday operations much faster and easier to accomplish. Enhancing this further with AI-driven analytics and process optimization empowers manufacturers and frontline personnel with the right tools for quality data collection and inspection procedures.

How standardizing QA and inspection procedures reduces errors

According to LNS Research, to digitize quality assurance processes, manufacturing leaders must leverage emerging technologies. This allows them to achieve step-change improvements across operations. When you standardize quality assurance procedures, you’re ensuring processes are completed using best practices and proven methods.

Think of it this way: When workers complete tasks using their own choice of tools, platforms, or reporting mechanisms, it’s harder to measure and evaluate which procedures are bringing value and which ones are not. It also leaves a lot of room for human error and inefficiency.

QA and inspection procedures should be standardized so that a worker’s way of doing things aligns with the company’s overarching objectives. If you don’t standardize inspection procedures, you’ll have a more difficult time pinpointing product deficiencies and worker errors.

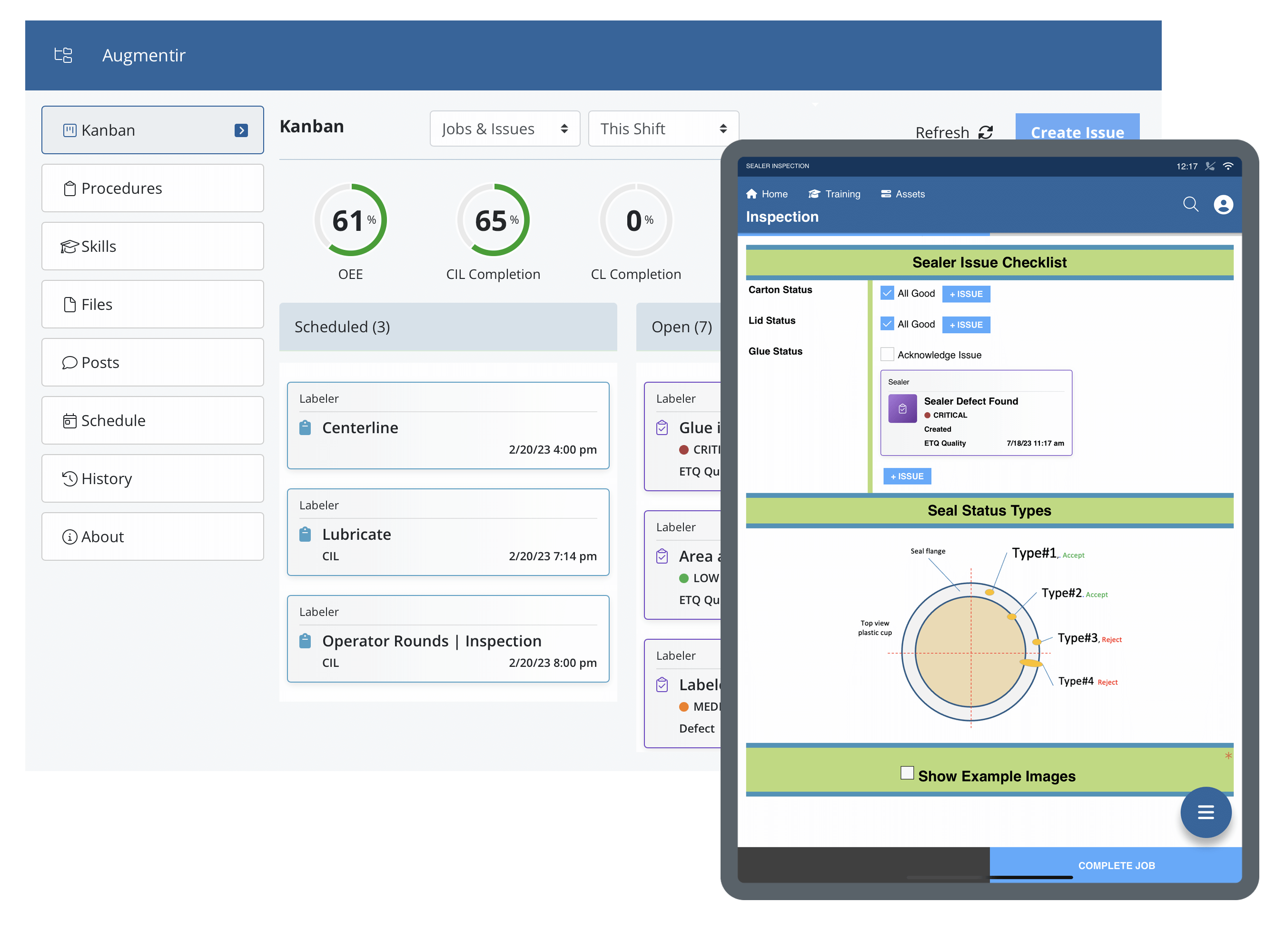

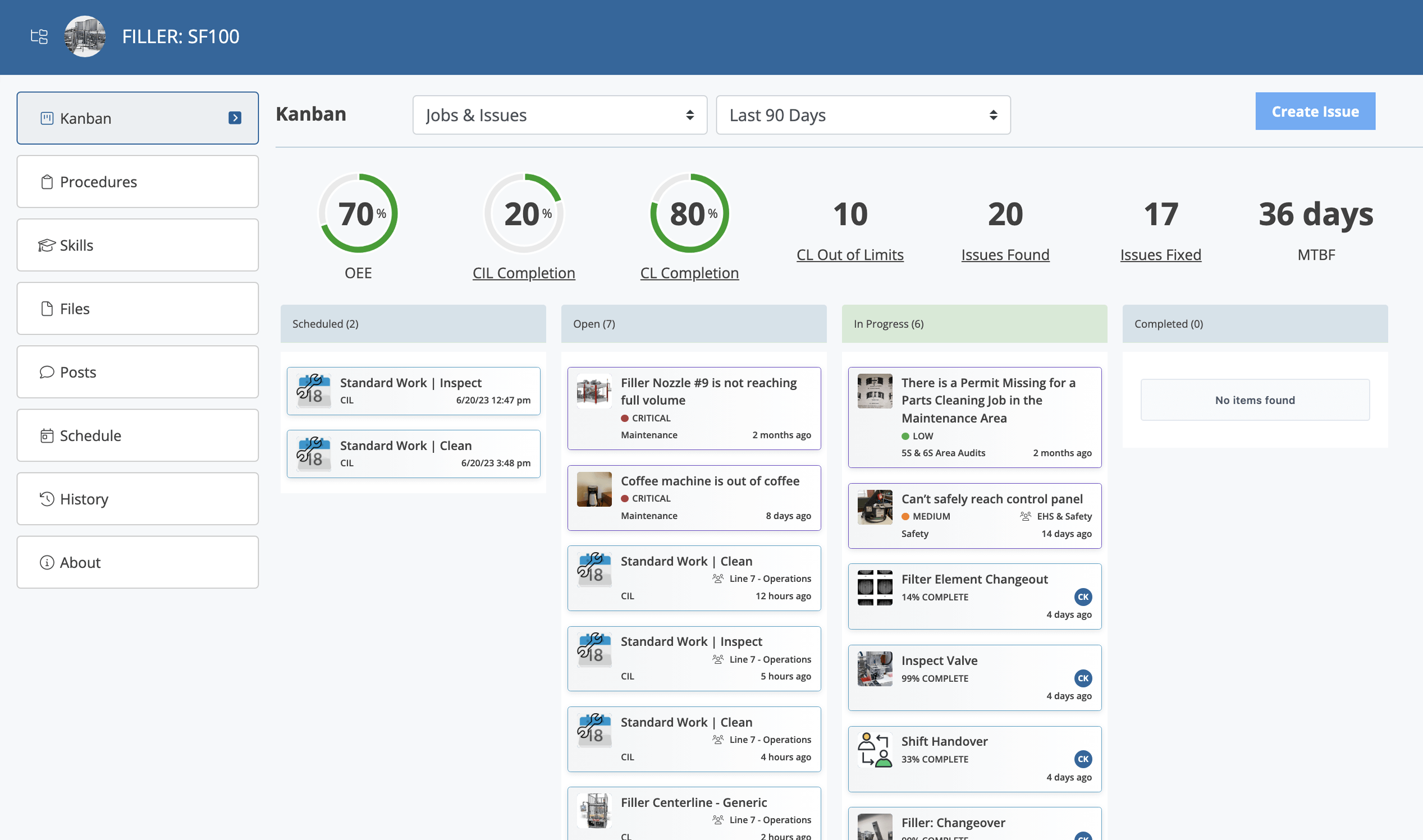

Smart, connected worker platforms and AI-based software allow manufacturers to standardize processes across all units, creating a single source of truth for a truly optimized procedure that can be audited and verified, resulting in fewer errors, reduced defects, and more expedited inspections overall. Every procedure, regardless of how often it’s performed, can have guidelines that define the scope and methods for how to perform it. This in turn ensures a higher quality result every time.

How digitizing quality assurance procedures minimizes mistakes

Converting your paper-based QA procedures to a digital format is one of the smartest things a manufacturer can do. From there, you can set up a unified system to improve QA assurance processes.

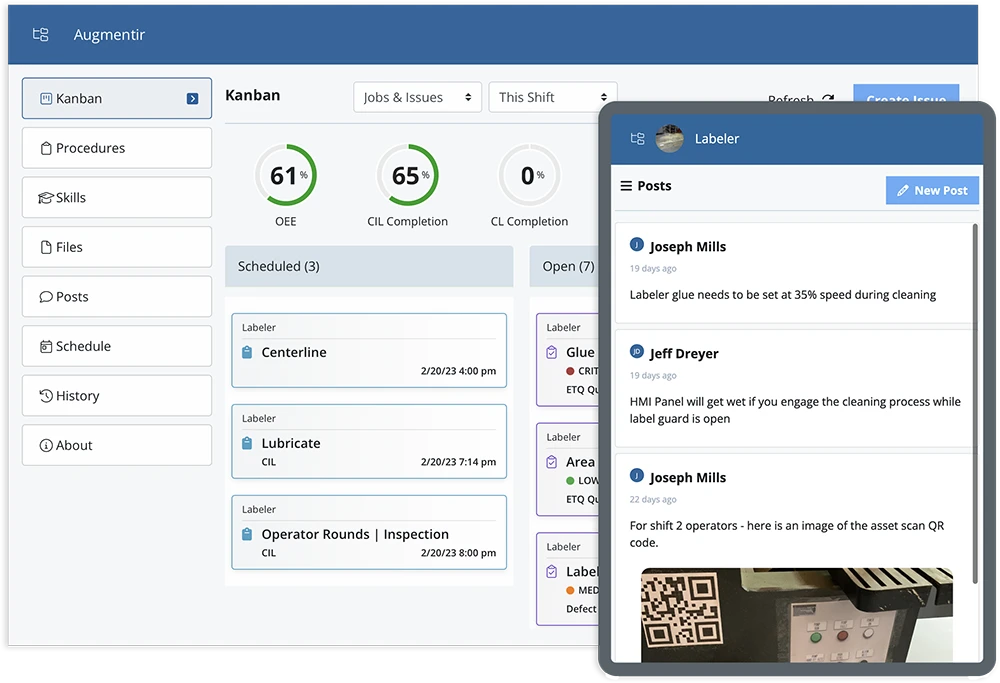

Workers are only human, and quality assurance systems safeguard the production process. It identifies mistakes as they happen and uses communication tools to reduce the risk of error. Other strategies such as a “first time quality” (FTQ) or first time right plan enhance standards, practices, and resources to ensure all processes on the production floor are performed correctly the first time.

Deploying an integrated system makes it easier to:

- Gradually improve your production processes

- Standardize your QA methods

- Digitize manufacturing processes

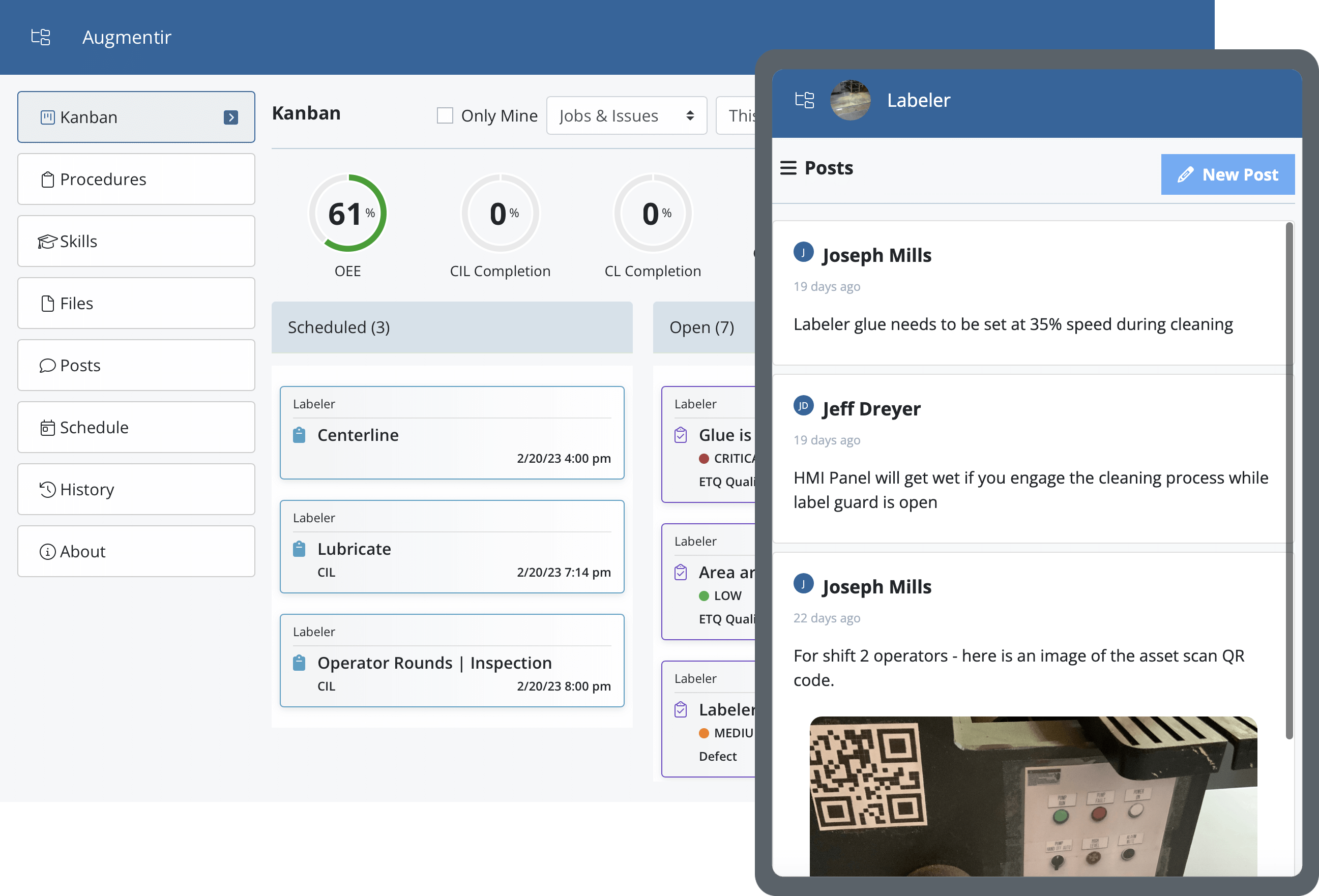

Connectivity and connected worker technology empowers all workers to do their jobs better and in a timelier manner. It also gives managers the opportunity to track how well employees are carrying out standardized QA procedures and inspections. When coupled with AI-driven analytics that can process the massive amounts of data connected workers generate, manufacturers are able to derive better insights, faster, and with higher reliability. This essentially transforms frontline workers into quality assurance sensors that further enhance and empower quality inspections.

If you’re still using paper checklists to track procedures, you’ll never see beyond what’s in front of you. By digitizing analog paper practices you are enabling better quality data collection and inspection procedures and strengthening your overall manufacturing operations.

Thankfully, Augmentir’s connected worker solution gives real-time visibility into all operational processes, from anywhere. Industrial companies use our breakthrough system to standardize and digitize quality assurance procedures.

If you are interested in learning for yourself why companies are choosing Augmentir to help standardize and digitize their quality assurance procedures – reach out to book a demo.