Learn how to digitize your operations and build a paperless factory in this paperless manufacturing guide from Augmentir.

Manually managing and tracking production in manufacturing has become a thing of the past. That’s because manufacturers are adopting a new digital approach: paperless manufacturing.

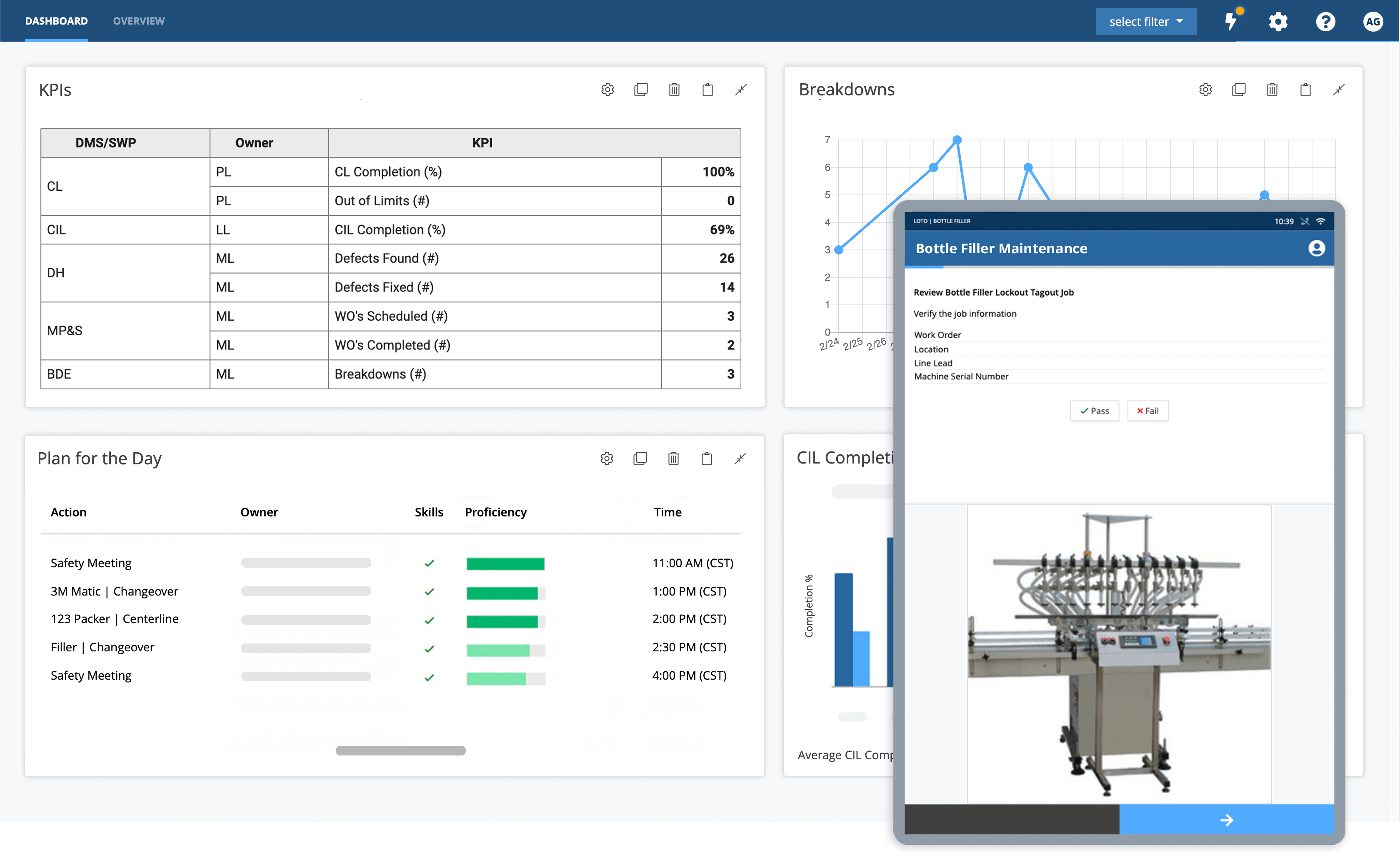

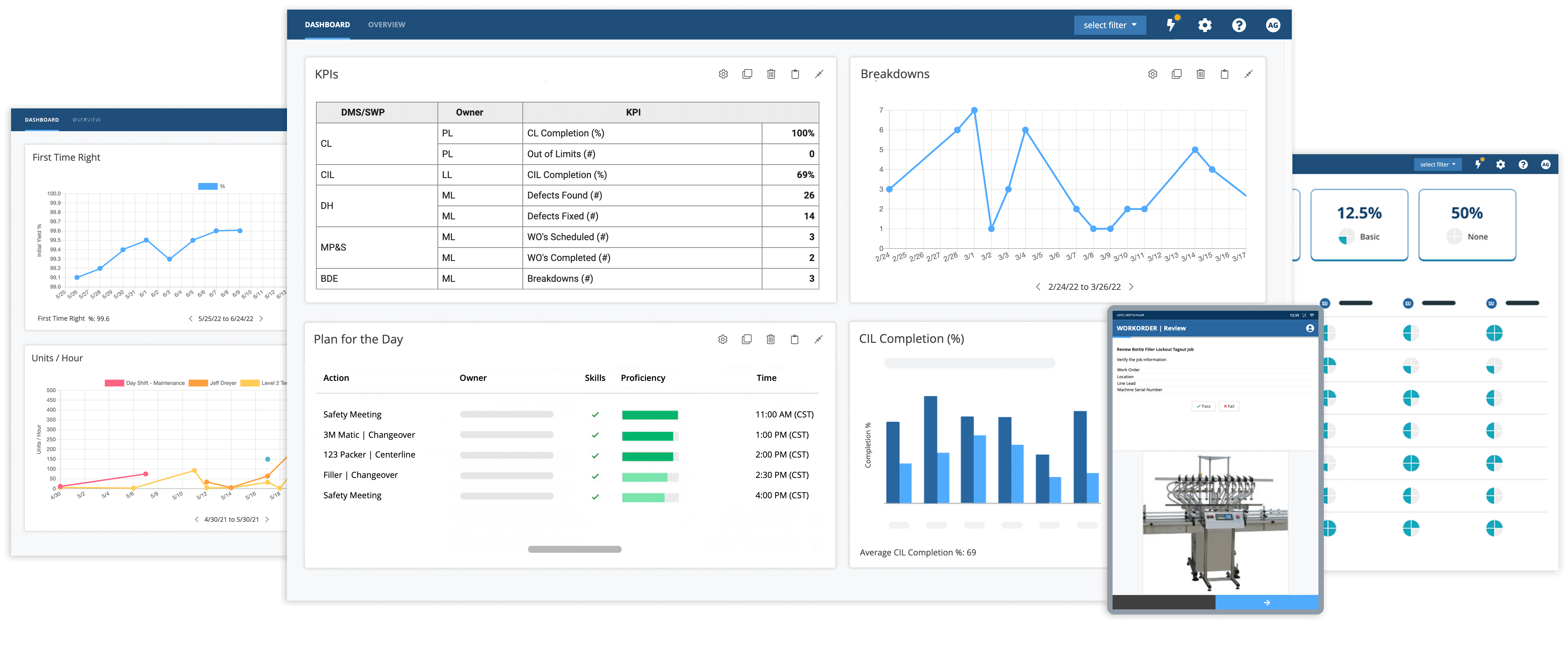

Paperless manufacturing uses software to manage shop floor execution, digitize work instructions, execute workflows, automate record-keeping and scheduling, and communicate with shop floor employees. More recently, this approach also digitizes skills tracking and performance assessments for shop floor workers to help optimize workforce onboarding, training, and ongoing management. This technology is made up of cloud-based software, mobile and wearable technology, artificial intelligence, machine learning algorithms, and advanced analytics.

More recently, your journey to paperless manufacturing is being accelerated through the availability of generative AI assistants and supporting import tools that can streamline the conversion of existing content into interactive, mobile-ready content for your frontline teams.

Paperless manufacturing software uses interactive screens, dashboards, data collection, sensors, and reporting filters to show real-time insights into your factory operations. If you want to learn more about paperless manufacturing processes, explore this guide to learn about the following:

- What is a paperless factory?

- What are the benefits of going paperless in manufacturing?

- How do you go paperless in manufacturing?

What is a paperless factory?

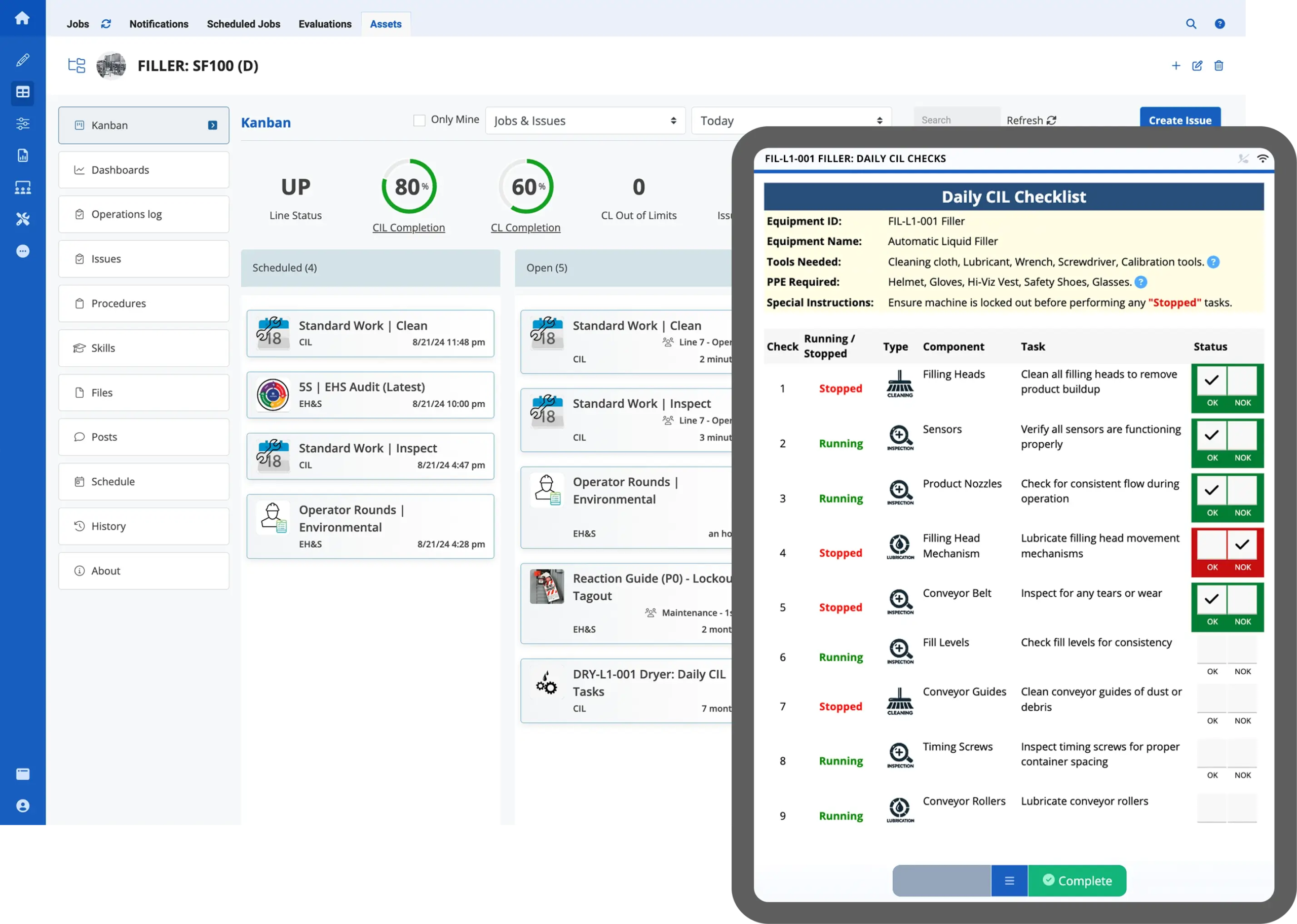

A paperless factory uses AI-powered software to manage production, keep track of records, and optimize jobs being executed on the shop floor. Paperless manufacturing is intended to replace written record-keeping as well as paper-based work instructions, checklists, and SOPs, and keep track of records digitally.

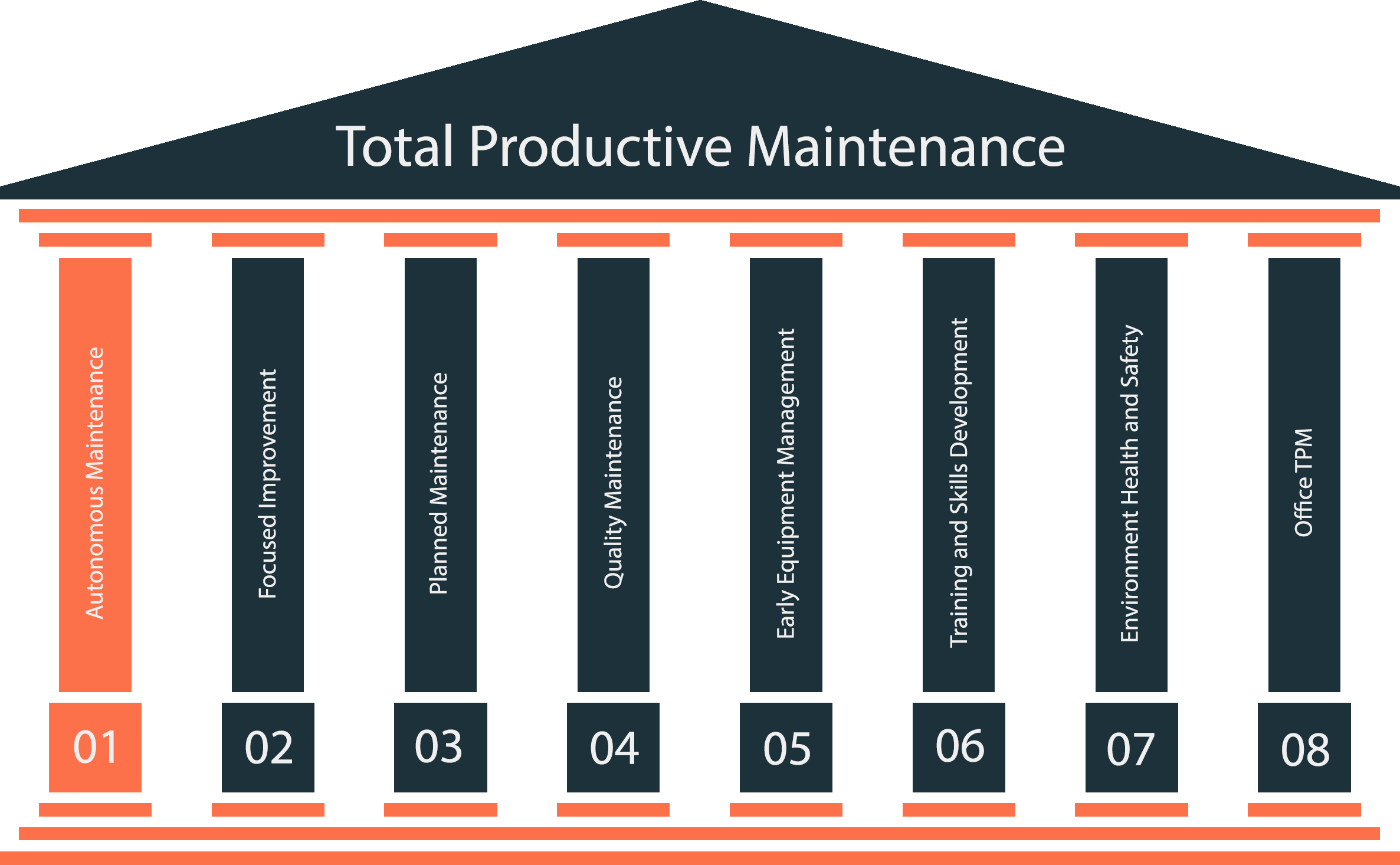

For example, in most manufacturing operations, everything from quality inspections to operator rounds and planned and autonomous maintenance is done on a regular basis to make sure factory equipment is operating properly and quality and safety standards are met. In most manufacturing plants, these activities are done manually with paper-based instructions, checklists, or forms.

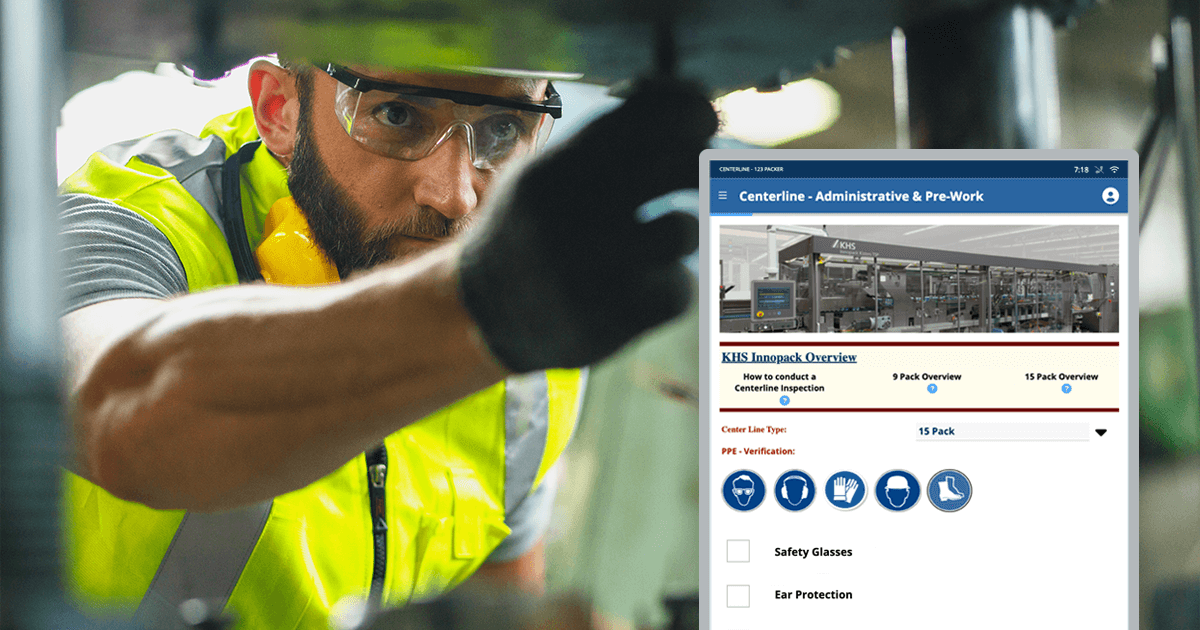

Operators and shop floor workers in paperless factories use software to execute work procedures and see production tasks in ordered sequences, which enables them to implement tasks accordingly. Workers are able to view operating procedures, or digital work instructions, using mobile devices (wearables, tablets, etc.) in real-time.

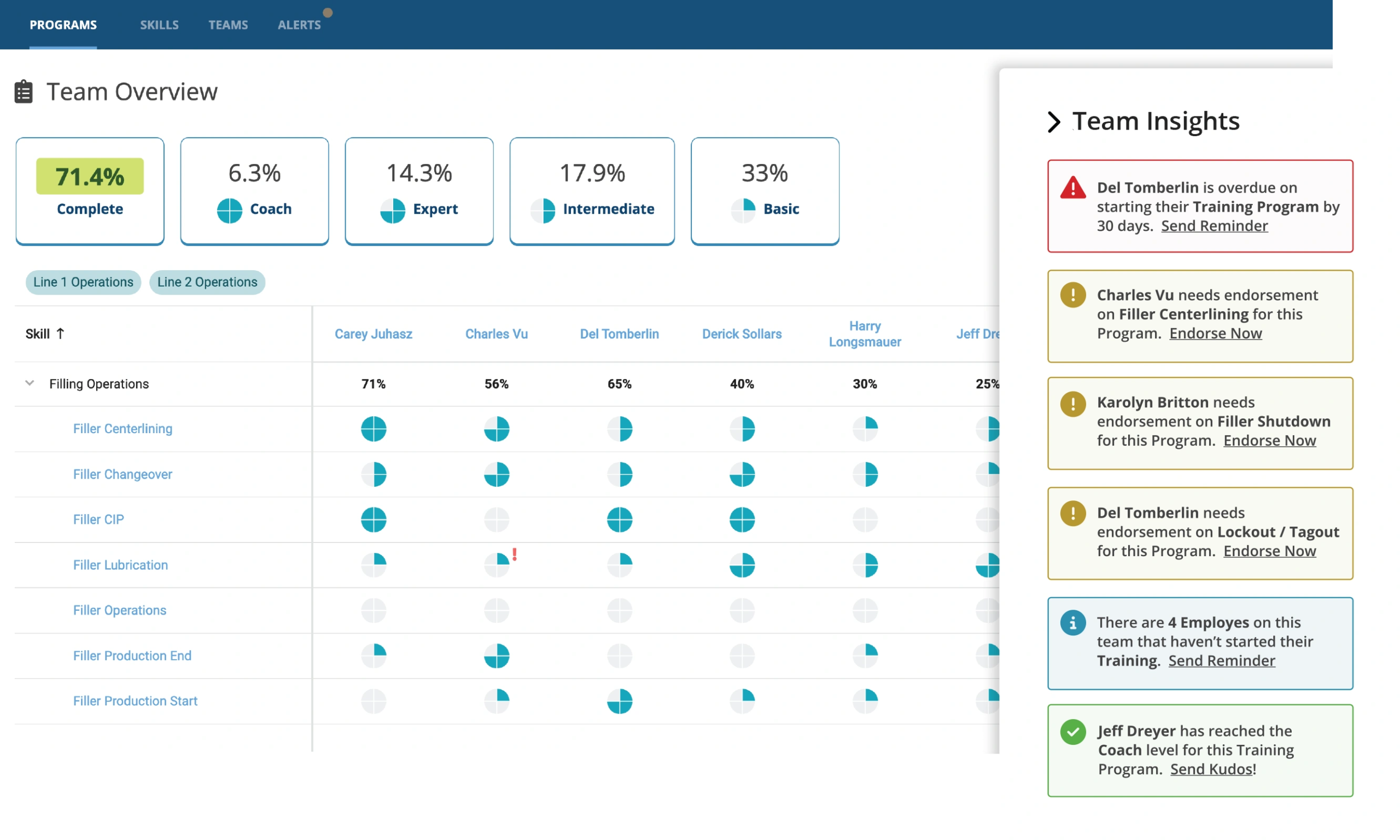

Furthermore, paperless manufacturing incorporates the digitization of shop floor training, skills tracking, certifications, and assessments. This digital approach uses skills management software helps optimize HR-based processes that were previously managed via paper or spreadsheets, and includes the ability to:

- Create, track, and manage employee skills

- Instantly visualize the skills gaps in your team

- Schedule or assign jobs based on worker skill level and proficiency

- Close skill gaps with continuous learning

- Make data-driven drive operational decisions

What are the benefits of going paperless in manufacturing?

There are a number of reasons for factories to go paperless, from cost-effectiveness to increased productivity and sustainability. A paperless system can revolutionize production processes, workforce management, and business operations.

Here are the top benefits of going paperless:

- Accelerate employee onboarding: By digitizing onboarding and moving training into the flow of work, manufacturers can reduce new hire onboarding time by 82%.

- Increase productivity: Digitizing manufacturing operations means no more manual, paper-based data collection or record-keeping. Workers have more time to run their equipment, execute shop floor tasks, and find solutions to problems.

- Boost data accuracy: People are prone to making mistakes, but digital data capture and validation can help offset human error and improve accuracy.

- Improved workforce management: Digital skills tracking and AI-based workforce analytics can help optimize production operations and maximize worker output.

- Manage real-time operations: Human-machine interface systems eliminate the need for paper, files, and job tickets. This means that workers can analyze inventory and other data in real-time.

- Save money: Although going paperless means that the cost of paper is eliminated, the savings extend beyond that. With greater productivity, operations in real-time, and improved production optimization, costs can be reduced in many areas.

How do you go paperless in manufacturing?

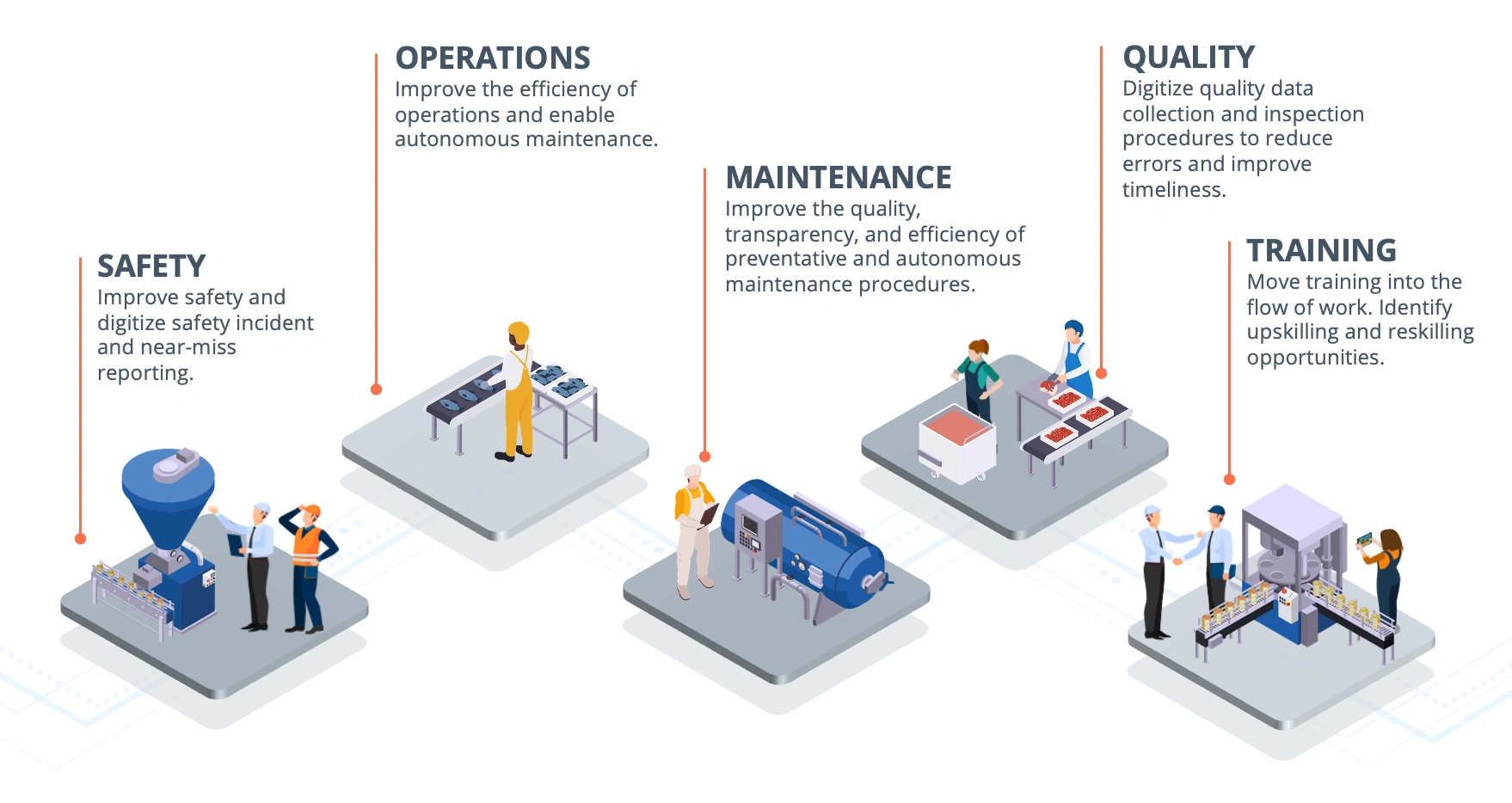

Going paperless starts with digitizing activities across the factory floor to increase productivity, and extending that value through a digital connection between the shop floor and enterprise manufacturing systems. We lay out below the four basic steps for how to go paperless in manufacturing:

Step 1: Digitize your existing content with Gen AI and Connected Worker technology.

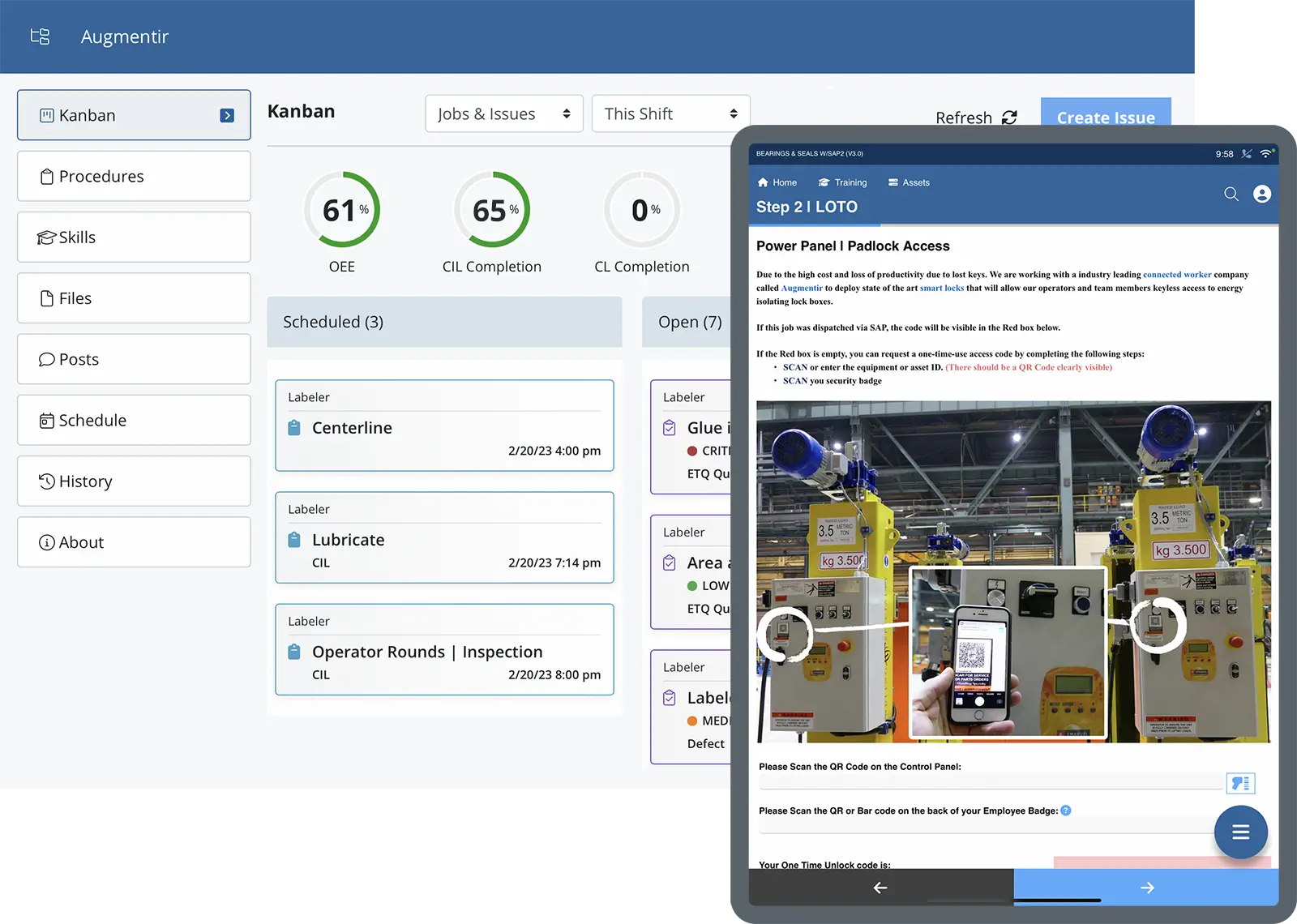

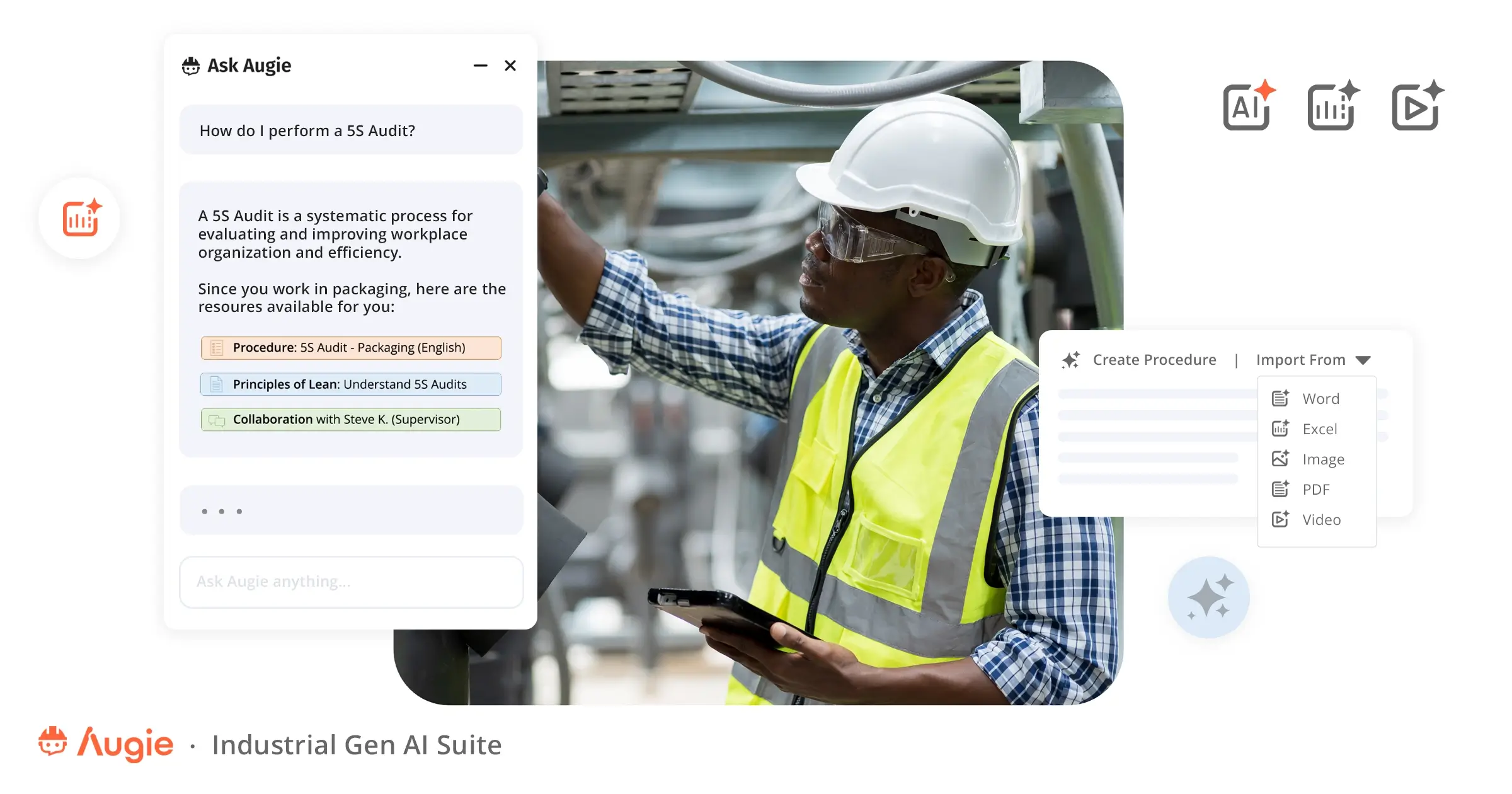

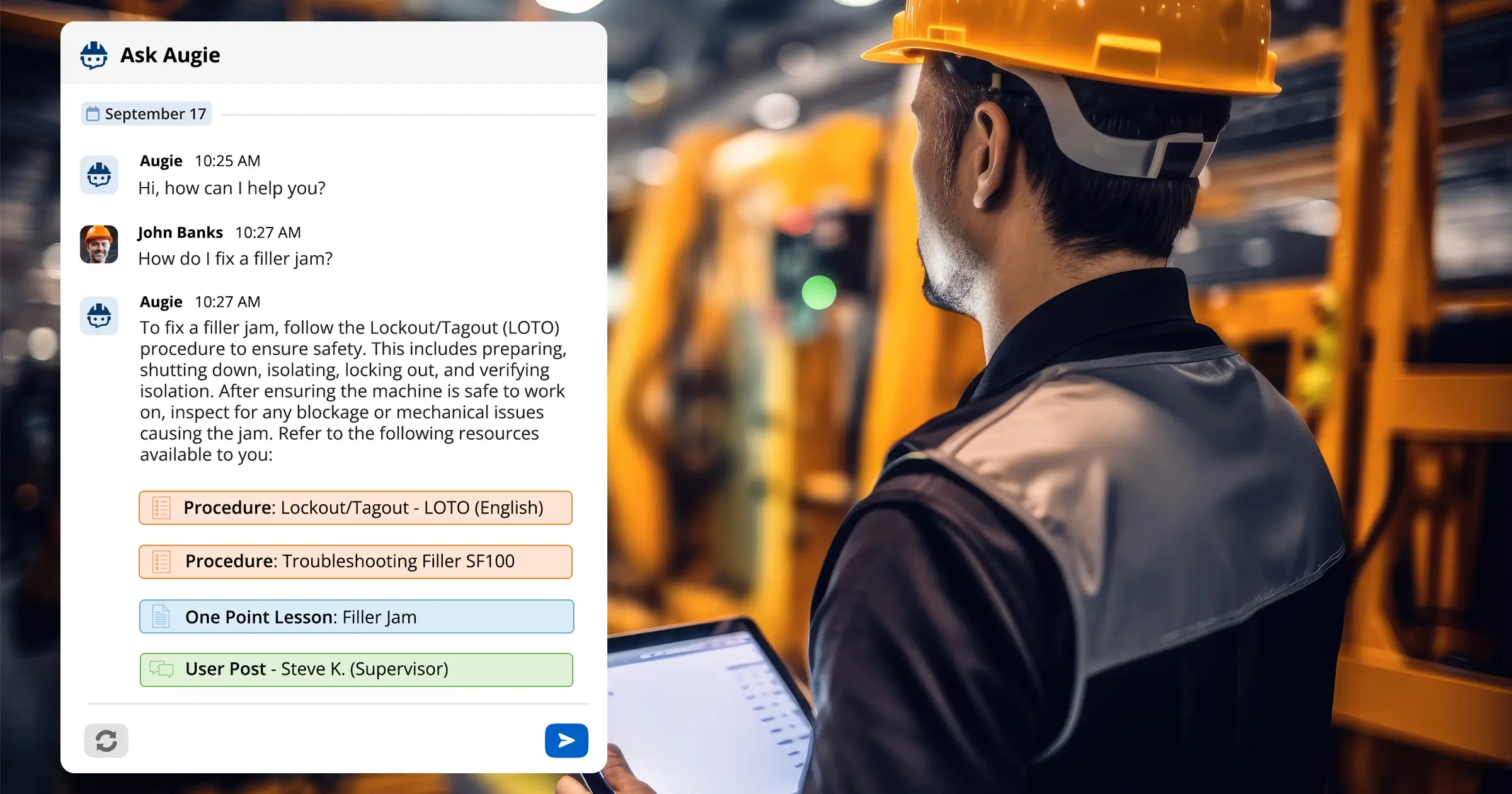

Paperless manufacturing starts with the use of modern, digital tools that can quickly and easily digitize and convert your existing paper-based content. Tools like Augmentir’s Augie™, a generative AI suite of technologies, helps you import and convert existing content regardless of format. Once converted, Connected Worker solutions that incorporate enhanced mobile capabilities and combine training and skills tracking with connected worker technology and on-the-job digital guidance can deliver significant additional value. A key requirement to start is to identify high-value use cases that can benefit from digitization, such as quality control or inspection procedures, lockout tagout procedures, safety reporting, layered process audits, or autonomous maintenance procedures.

You can now import existing PDF, Word, or Excel documents (just like the PDF above) directly into Augmentir to create digital, interactive work procedures and checklists using Augie™, a Generative AI content creation tool from Augmentir. Learn more about Augie – your industrial Generative AI Assistant.

Step 2: Augment your workers with AI and Connected Worker technology.

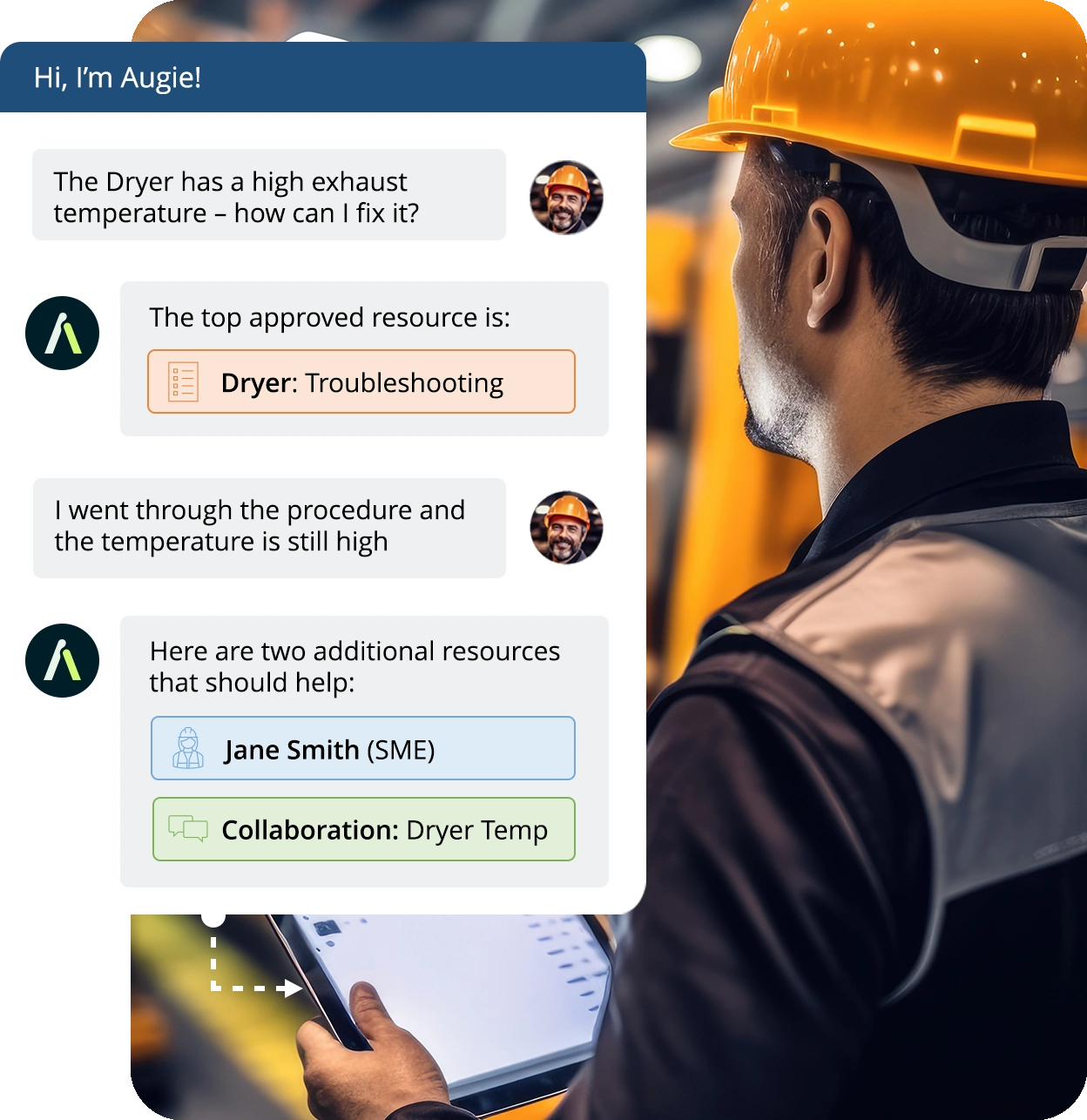

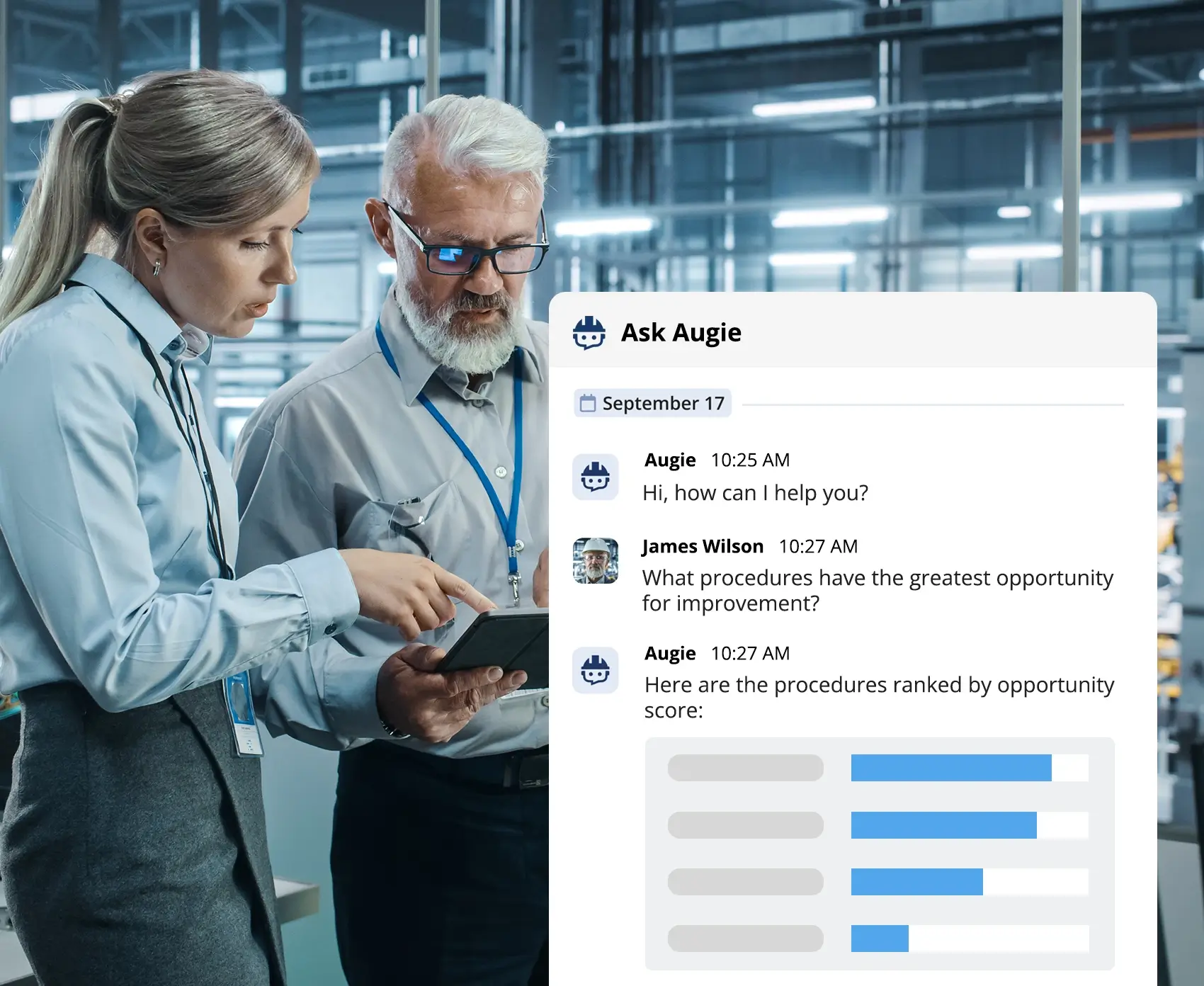

AI-based connected worker solutions can help both digitize work instructions and deliver that guidance in a way that is personalized to the individual worker and their performance. AI Bots that leverage generative AI and GPT-like AI models can assist workers with language translation, feedback, on-demand answers, access to knowledge through natural language, and provide a comprehensive digital performance support tool.

As workers become more connected, companies have access to a rich source of job activity, execution, and tribal data, and with proper AI tools can gain insights into areas where the largest improvement opportunities exist.

Step 3: Set up IoT sensors for machine health monitoring.

The industrial Internet of Things (IoT) uses sensors to boost manufacturing processes. IoT sensors are connected through the web using wireless or 4G/5G networks to transmit data right from the shop floor. The use of machine health monitoring tools along with connected worker technology can provide a comprehensive shop floor solution.

Step 4: Connect your frontline to your enterprise.

Digitally connected frontline operations solutions not only enable industrial companies to digitize work instructions, checklists, and SOPs, but also allow them to create digital workflows and integrations that fully incorporate the frontline workers into the digital thread of their business.

The digital thread represents a connected data flow across a manufacturing enterprise – including people, systems, and machines. By incorporating the activities and data from these previously disconnected workers, business processes are accelerated, and this new source of data provides newfound opportunities for innovation and improvement.

Augmentir provides a unique Connected Worker solution that uses AI to help manufacturing companies intelligently onboard, train, guide, and support frontline workers so each worker can contribute at their individual best, helping achieve production goals in today’s era of workforce disruption.

Our solution is a SaaS-based suite of software tools that helps customers digitize and optimize all frontline processes including Autonomous and Preventive Maintenance, Quality, Safety, and Assembly.

Transform how your company runs its frontline operations. Request a live demo today!