Augmentir’s take on the trending Workforce Institute’s staggering survey numbers.

Everyone is talking about it. The skilled labor shortage. It’s not a temporary problem. It’s here to stay. So instead of panicking and trying to use the same old strategies to identify, recruit and retain the increasingly rare skilled and experienced worker, let us present a different way of looking at the labor challenge. Spoiler alert: we see opportunity!

But first, let’s unpack some recent survey findings about the labor market.

According to a survey by the Workforce Institute, a whopping 87 percent of manufacturers are feeling the ramifications of the shortage of skilled labor, including staff misalignment along the production lines, burnout, and supply chain disruption.

Finding workers with the right skills, education and certifications can feel like looking for a needle in a haystack–hopeless and painful. The shrinking talent pool is forcing companies to rehire former employees who previously quit with limited skills or individuals with no manufacturing experience; it probably feels like the only viable option for production survival.

Where do you start with this new variable workforce? Standardized training programs? Excel spreadsheets for tracking and monitoring? These methods pose a concern for all workers on your production lines, regardless of their experience or skill set. Who needs what training? Who is responsible for tracking productivity and capturing relevant data? How confident are you in endorsing skills and assigning production teams with limited or imprecise information?

The old way would have led to panic. Today, there’s a better, smarter way. Today’s variable workforce in the manufacturing world is perfectly suited to adopt smart technology that will reduce, if not eliminate, the challenges associated with the labor shortage. Remember that thing we said about opportunity? Here it is.

Stay calm and carry on: smart digital tech can have an immediate and direct impact on learning about and managing worker skills.

Imagine if you could learn about a worker’s skills by tracking their performance in real time, immediately deliver training resources tailored to them based on their proficiency and certifications and then match them confidently to a production team where they’ll make a meaningful contribution. Sound like wishful thinking? It’s not.

Smart connected worker technology can collect data on worker patterns by tracking their performance journeys. It pulls relevant resources from the company inventory to deliver customized training programs. With the right training in place workers are engaged and feel safe while performing tasks. And, your teams are equipped to meet productivity goals.

The labor shortage is just a statistic. A smart connected worker suite is the solution.

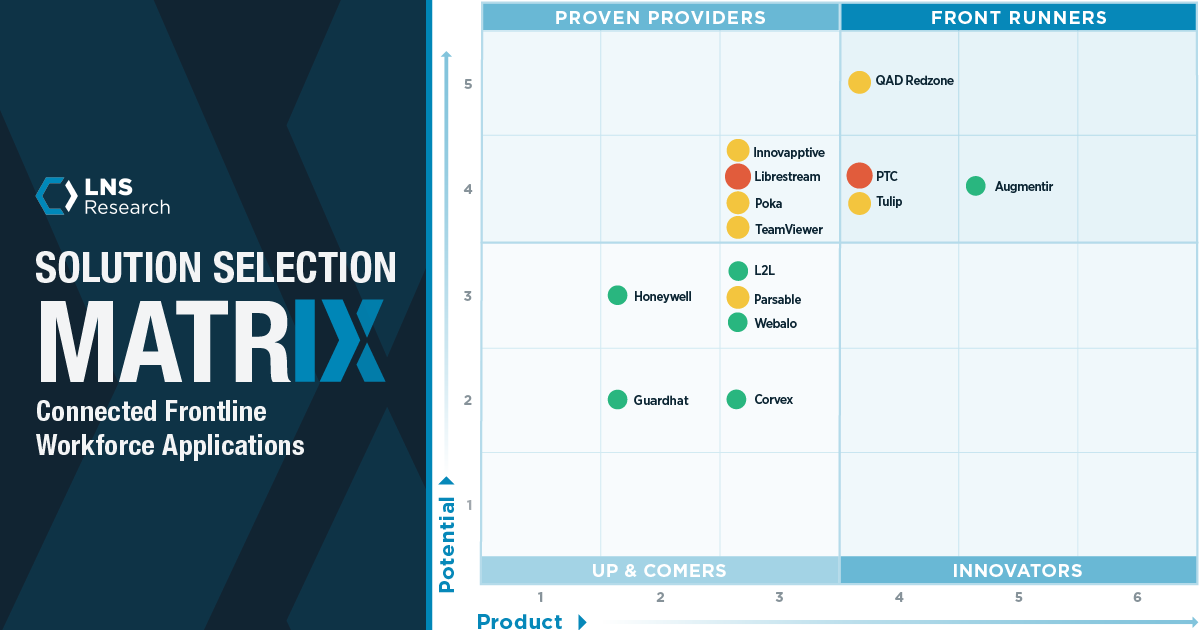

Augmentir’s smart connected worker suite closes the gap between training and worker execution. Digitized instruction and skills management programs display and organize workers’ proficiencies based on levels of expertise. AI-driven insights monitor and easily match workers with procedures by assigning skills criteria. This proprietary Smart AI technology intelligently prompts workers for continuous training and accurately identifies appropriate skills endorsements to managers, helping them create better production lines. It’s the only solution of its kind on the market.

Kylene Zenk, Director of the Manufacturing Practice at UKG sees opportunity, too:

“If you can offer training or can tailor a job to meet candidates’ flexible qualifications, filling open headcount becomes more realistic in a tight labor market.”

We couldn’t agree more. Find out more about how and why manufacturers are taking smarter approaches to building a strong talent pipeline with Augmentir. Contact us for a demo today.