Smart Skills Management software is helping manufacturers bridge the gap between training, skills, and work to build a more resilient and agile workforce.

Where are you on your journey with adopting new and emerging technologies? Many manufacturers are jumping on the bandwagon for some of the latest tools that provide digital guidance to workers. Maybe you decided to implement digital work instructions to help workers safely and efficiently perform tasks. Or maybe you’ve bought skills management software to help you catalog and organize the skills and capabilities of different workers. But are either of these enough on their own to achieve all your production goals? Possibly, but unlikely.

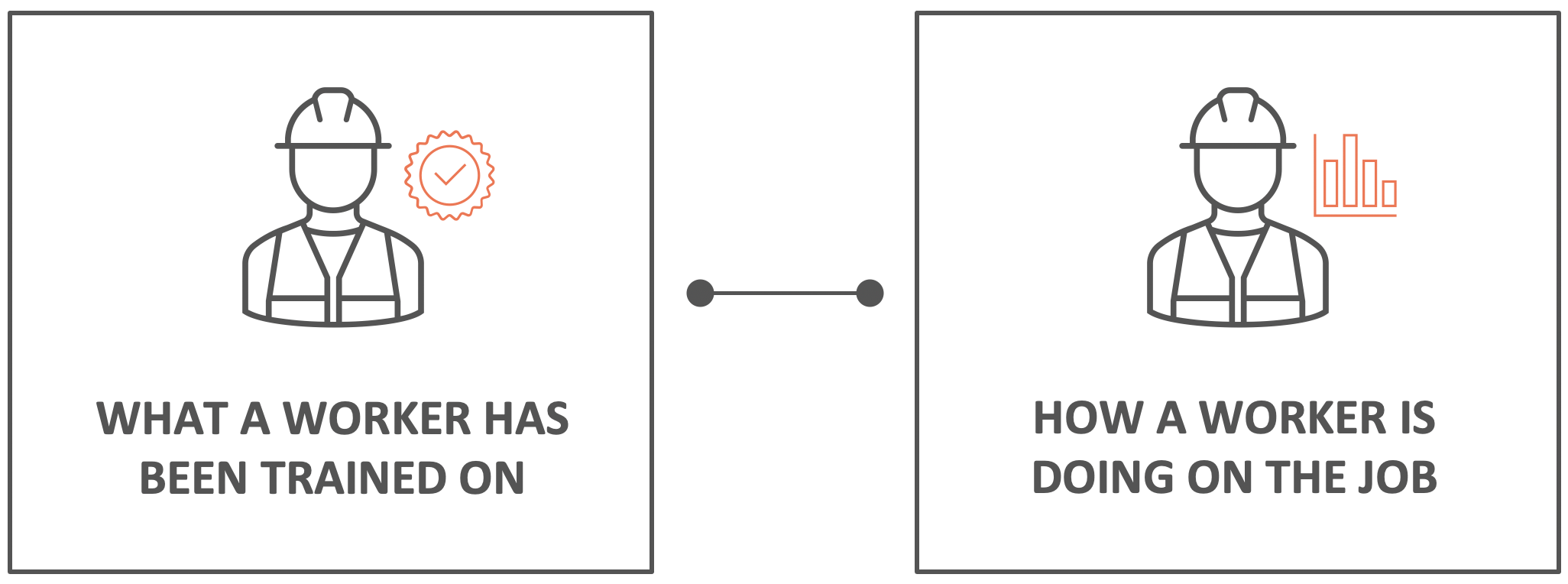

Digital work instructions on their own deliver standard work guidelines but fail to consider the unique skills of each worker. Standalone skills management programs may offer a highlight reel of the skills and certifications of your workers but neglect to capture performance in real-time to provide accurate skills evaluations. Nor do they offer personalized training content needed to ensure workers perform their absolute best. Can we agree then these two features should go hand-in-hand?

One cannot exist without the other: Blending skills into the flow of work

In the past, standalone skills management systems were sufficient because:

- Turnover was infrequent so line supervisors knew everyone on their team and their current skills and endorsements, making it easy for the supervisor to assign work safely and optimally

- Investments in training, reskilling, and upskilling were performed either in a one size fits all approach or through a purely subjective or anecdotal approach

Today, however, a different situation exists.

Line supervisors are dealing with team members that they don’t know well, new ones starting every day, and experienced ones leaving. This creates safety issues and makes optimally assigning work difficult as not only are the workers variable, but their skill levels and certifications are a constantly moving target.

An integrated, closed-loop skills management system is the solution for this era of high workforce turnover and absenteeism.

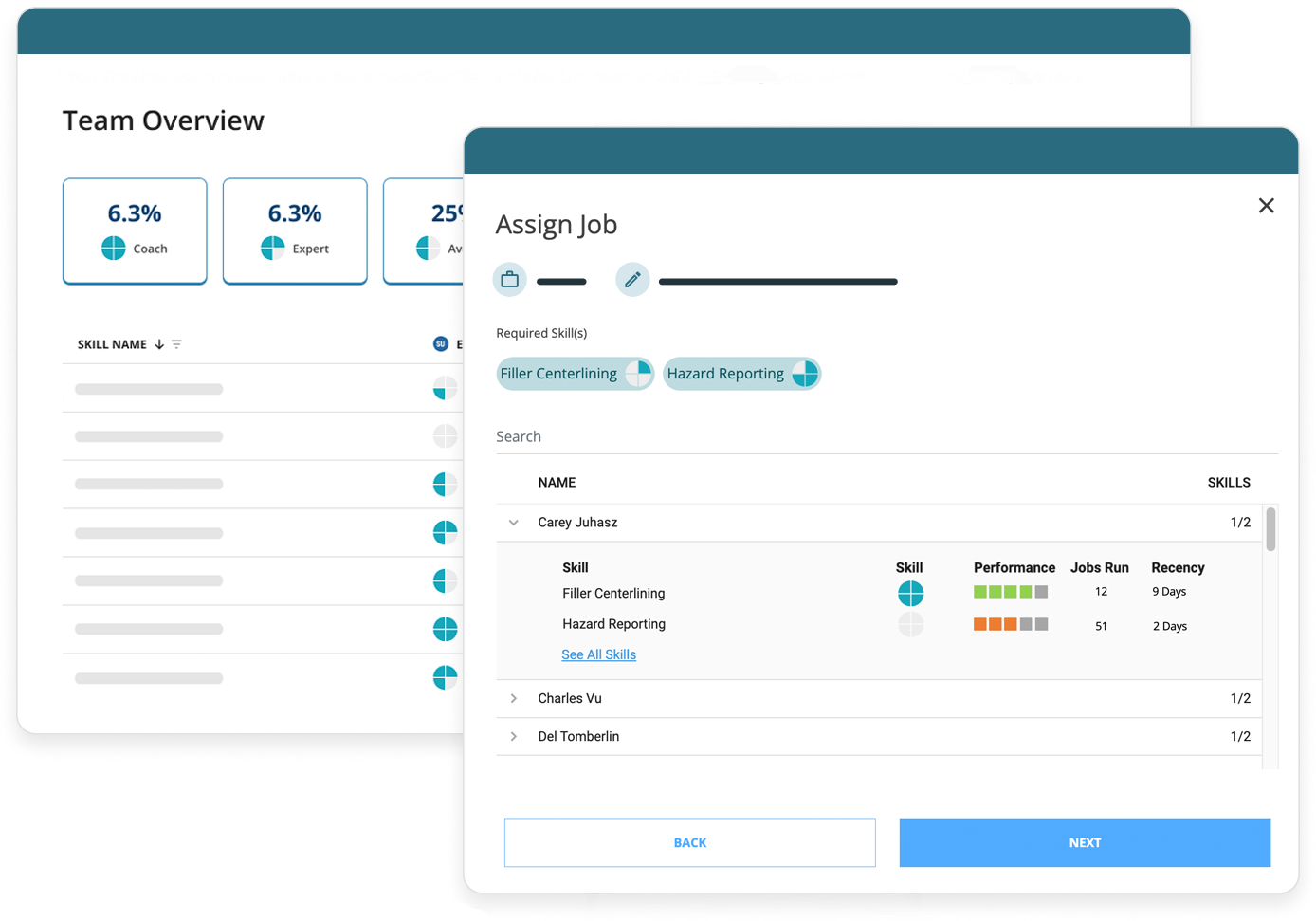

Skills management solutions that combine skills tracking capabilities with connected worker technology and on-the-job digital guidance can deliver significant additional value. Data from actual work performance can inform workforce development initiatives allowing you to target your training, reskilling, and upskilling efforts where they have the largest impact.

It can generate an abundance of valuable data to provide tailored training support and skills endorsements and identify workforce opportunities. What else is possible? Imagine reducing training costs, optimizing job scheduling, increasing safety, and improving productivity. And now consider what will happen when you add smart technology to this all-in-one package.

The power of smart digitization! Skills management and digital work instructions together boost productivity.

According to Deloitte, organizations are shifting to a skills-based approach to meet the demand for agility, agency, and equity. Connected worker solutions that combine skills management with digital work instructions, collaboration, and knowledge management are uniquely suited to optimize today’s variable workforce. AI-generated insights are pulled from patterns identified across all work activity in real-time. These insights identify where new and experienced workers may benefit from either reskilling or upskilling.

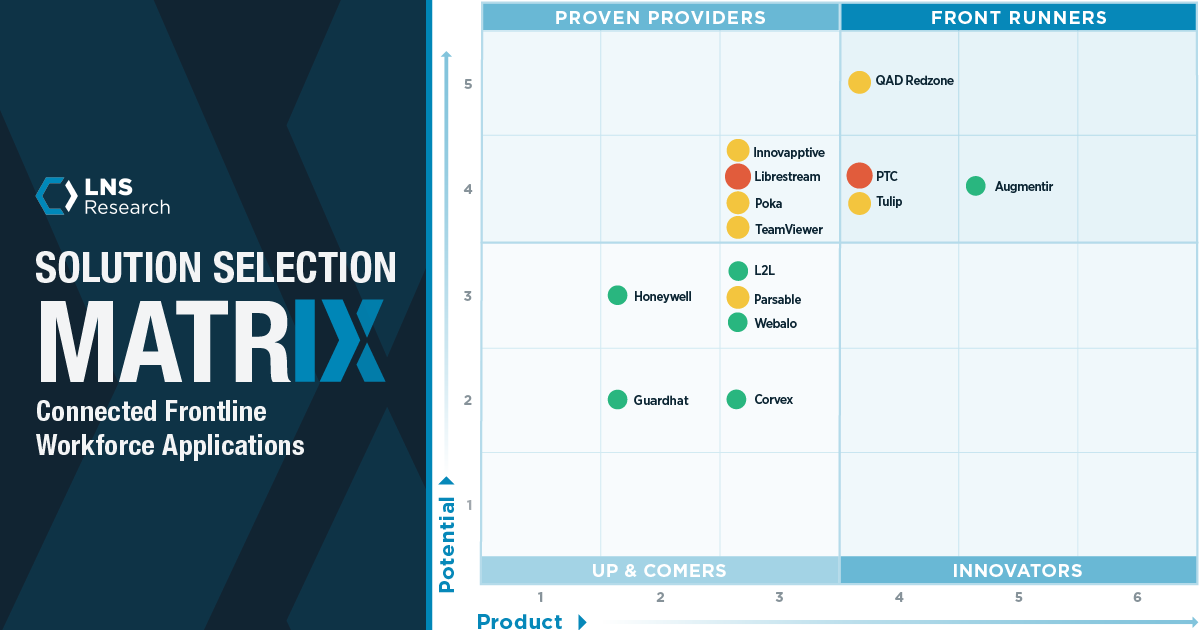

This combination of smart digital technology can also leverage your training resources, such as instructional videos, written instructions, or access to remote experts, to deliver personalized guidance for the worker to perform their best. These tools intelligently work together to help you assign workers to procedures based on required skill levels. No second guessing! Augmentir is the only smart connected worker solution to intertwine these management tools with AI making it a powerhouse for optimizing your operations and meeting production targets.