Learn how digital and mobile operator rounds make manufacturing inspections safer and enhance overall operational excellence.

Mobile and digital operator rounds significantly enhance manufacturing activities by providing real-time data collection, analysis, and decision-making capabilities. Applying mobile technology and digitizing operator rounds connects and empowers manufacturing workers and organizations with improved operational efficiency, equipment uptime, and drives continuous improvement initiatives, ultimately leading to greater operational excellence.

Operator rounds in manufacturing refer to a systematic process where operators or technicians conduct routine inspections and checks on various equipment, machinery, and systems within a manufacturing facility. During operator rounds, operators inspect equipment, check for leaks, listen for unusual sounds, monitor gauges and indicators, and perform basic tests or measurements to ensure that equipment is operating as intended, identify potential problems or maintenance needs early on, and prevent unexpected downtime or failures that could disrupt production.

Operator rounds are an essential part of a preventative maintenance strategy, helping to improve equipment reliability, extend asset lifespan, and optimize overall manufacturing operations. They also provide operators with the opportunity to become more familiar with the equipment they are responsible for and to detect and address any safety concerns.

Read below to learn more about digital and mobile operator rounds, the benefits they offer versus traditional paper-based operator rounds, key aspects to include in an operator round checklist, and how AI-driven insights and connected frontline worker technology transforms the operator round process for enhanced results.

- Paper-based Operator Rounds vs. Digital Operator Rounds

- Key Aspects of an Operator Round Checklist

- Transforming Operator Rounds with AI-powered Connected Worker Technology

Paper-based Operator Rounds vs. Mobile and Digital Operator Rounds

According to Forbes, the average manufacturer encounters 800 hours of equipment downtime per year — more than 15 hours per week, with an estimated total cost of $50 billion per year. Further studies found that human procedural error contributed to 405 fatalities, 2,163 injuries, and over $150 billion in losses for manufacturers.

So why do many plant operators still use paper-based checklists and forms when conducting critical inspections?

In many cases, it is simply a matter of tradition, and when given the opportunity to make the process easier and more efficient with digital solutions, operators and manufacturers alike are eager to embrace the change.

Comparing paper-based operator rounds with mobile and digital operator rounds in manufacturing highlights several key differences in terms of efficiency, effectiveness, and overall impact on operational excellence.

Paper-based operator rounds in manufacturing can be boiled down to 4 main steps:

- Managers or supervisors create an operator round checklist/form

- The operator executes the round and writes the observations on a paper sheet

- In the instance of any uncertainties or issues workers need to stop the round and ask for assistance or guidance

- The worker then delivers the completed checklist to their manager, who incorporates it into an ERP system or other management tool

Compliance is difficult when using paper spreadsheets and word processor documents. Routes or routines that still use paper checklists must be manually entered into a spreadsheet or database. This not only creates double work, but issues such as:

- Decreased visibility into facility-wide inspection activities

- Inconsistent records

- Lower anomaly detection and slower response

- Remedial and follow-up procedures are not automatic

- No access to immediate guidance or key information

- Lack of operational context in potentially hazardous environments

Mobile operator rounds and digital operator rounds, however, enable manufacturers and technicians to accelerate inspections, improve accuracy and compliance, and enhance operational excellence and efficiency through:

- Real-time data collection

- Immediate access to expert guidance or critical information

- Automated alerts or notifications

- Optimized processes and inspections

- Remote collaboration

- Enhanced compliance and digitized documentation

Connected devices enable operators to capture data, such as equipment readings, inspection results, and maintenance activities, directly at the point of operation. This eliminates the need for manual paperwork, reduces the risk of errors, and ensures that data is captured promptly and accurately. Additionally, digital operator rounds allow operators to access equipment manuals, schematics, and historical data instantly via mobile devices. This enables them to troubleshoot issues more effectively, follow proper procedures, and make informed decisions without delay.

Digital operator rounds systems can even streamline task assignment, tracking, and completion. Supervisors can assign tasks to operators, monitor progress in real-time, and prioritize work based on criticality and resource availability. This ensures that maintenance activities are performed efficiently and promptly. Overall, mobile and digital operator rounds empower manufacturing organizations to improve operational efficiency, maximize equipment uptime, and drive continuous improvement initiatives, ultimately leading to greater operational excellence.

Key Aspects of an Operator Round Checklist

An operator round checklist in manufacturing serves as a structured guide for operators to systematically inspect equipment, monitor performance, and identify potential issues during routine rounds. Here are key aspects to include in an operator round checklist:

- Inspection Identification: Clearly list the equipment, machinery, or systems that need to be inspected during the rounds.

- Visual Inspection: Include visual inspection items such as looking for leaks, cracks, signs of wear or damage, loose connections, abnormal vibrations, or any other visible abnormalities.

- Safety Features: Verify the functionality of safety features and emergency shutdown systems to ensure compliance with safety regulations and protocols.

- Functional Checks: Include functional checks to ensure that equipment is operating as intended. This may involve verifying that motors, pumps, valves, sensors, and other components are functioning properly.

- Process Measurements and Readings: Include items that require measurements or readings, such as temperature, pressure, flow rates, voltage, current, or any other relevant parameters.

- Quality Assurance: Ensure that quality checks are performed at each stage of the process and that products meet the quality parameters for each section.

- Training and Qualifications: Ensure that operators conducting the rounds are adequately trained and qualified to perform the inspections and understand the importance of their role in equipment maintenance and reliability.

- Special Instructions or Procedures: Include any special instructions, procedures, or precautions to be followed during the inspection, such as lockout/tagout procedures, safety protocols, or specific operating instructions.

- Comments, Feedback, and Continuous Improvement: Encourage operators to provide feedback on the checklist and suggest improvements based on their observations and experiences during the rounds. Regularly review and update the checklist to incorporate lessons learned and optimize inspection processes.

Additionally, consider breaking down the inspection into specific points or components to be checked on each piece of equipment. This may include mechanical components, electrical systems, fluid levels, safety features, etc. Other potential aspects that can be considered or included are documentation requirements, reporting and communication specifications, and inspection schedule and frequency. By including these key aspects in an operator round checklist, manufacturing organizations can ensure thorough and consistent inspections, identify issues early, prevent unplanned downtime, and maintain equipment reliability and operational excellence.

Transforming Operator Rounds with AI-powered Connected Worker Technology

AI and smart connected worker technology are revolutionizing a wide range of manufacturing operational processes, including operator rounds. By introducing advanced capabilities for data analysis, frontline worker augmentation, and better connectivity, these emerging technologies are transforming traditional operator rounds allowing for enhanced predictive maintenance, remote guidance and support through Generative AI assistants, workflow optimization, and improved safety compliance.

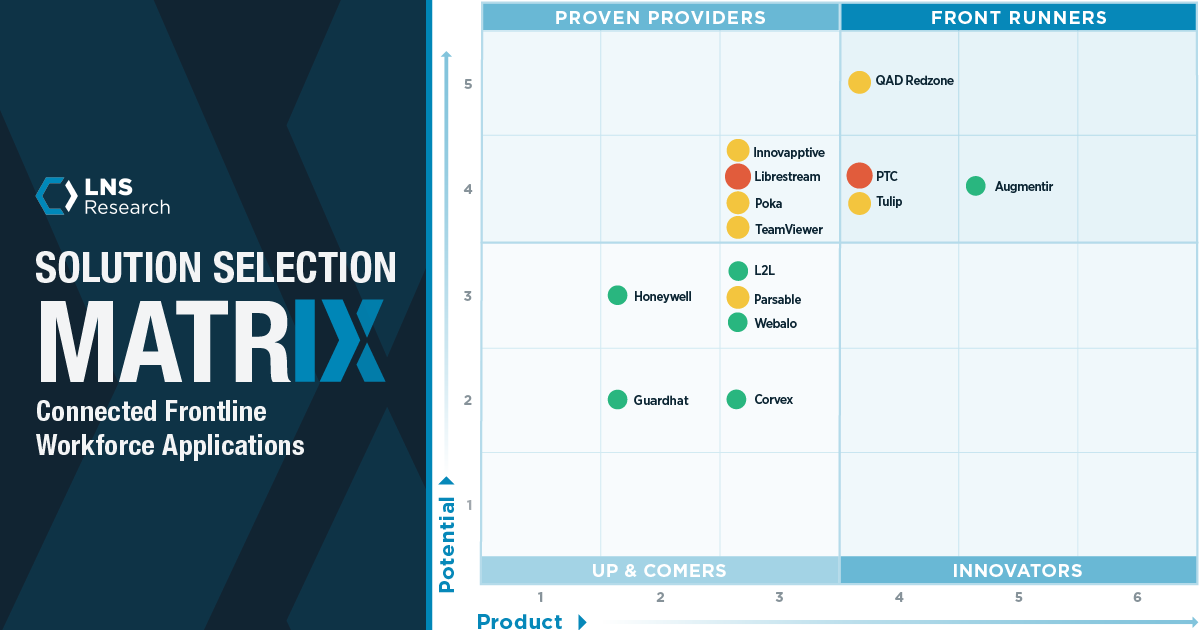

With AI and smart connected worker technology, manufacturing organizations can optimize operator rounds, maximize equipment uptime, minimize maintenance costs, and achieve operational excellence in an increasingly digital and data-driven environment. Augmentir’s connected worker solution, for example, offers tailored solutions for improving a wide range of operational processes, including operator rounds.

Using Augmentir’s No-Code workflow builder, companies can quickly convert paper-based instructions and checklists to a digital format and tailor those digital instructions to meet the needs of individual operators with inline training, built-in collaboration, and troubleshooting support. Additionally, Augmentir has internal PaaS services to run connectors that we build and support for popular enterprise applications like SAP, Salesforce, ETQ, Oracle, IBM Maximo, and more. Allowing our system to easily, bi-directionally, and securely integrate the enterprise systems of record to create closed-loop processes involving the frontline workforce.

Schedule a demo to learn more about our AI-powered connected worker solutions and how they dramatically improve manufacturing operational processes like operator rounds through digital and mobile technology, enable personalized skills management and training, and optimize manufacturing activities.