A connected worker strategy is critical to the success of your connected enterprise and digital transformation initiatives.

In today’s always-changing industrial landscape, organizations are acutely aware that adopting innovative technologies and processes is not just a “nice-to-have” but a “must” to stay competitive. According to PwC, 75% of manufacturers believe that Connected Enterprise technologies will have a major impact on their business over the next five years. By 2025, the number of connected devices in industrial settings is expected to reach 21.5 billion, making it clear that the adoption of connected technologies is a critical step for any organization that wants to succeed in the future.

However, there is one aspect of a truly connected enterprise that many manufacturers overlook – their frontline workforce.

Frontline workers play a critical role in ensuring the safety, quality, and uptime of production operations, yet too often these workers are disconnected from the rest of the business. Connected frontline worker (CFW), refers to the use of technology to connect workers with the digital systems and processes in their organization, making it easier for them to collaborate, access information, and perform their jobs more efficiently. To fully realize the benefits of a connected workforce, it is essential to understand how they fit into the larger Connected Enterprise concept.

Learn more about what a connected enterprise is and the role that connected worker solutions play in the following sections:

- What is a connected enterprise?

- How to create a connected enterprise

- Key benefits of connected worker solutions as part of your connected enterprise

- Implementing a connected enterprise with Augmentir

What is a connected enterprise?

Connected Enterprise refers to the integration of digital technologies, data, and analytics across an organization’s entire operational landscape to improve efficiency, productivity, and profitability. Companies are rapidly adopting advanced technologies to improve their business operations. This concept spans several initiatives within an organization: assets and equipment, the products being manufactured, the end customer, operations, workers, and the entire supply chain.

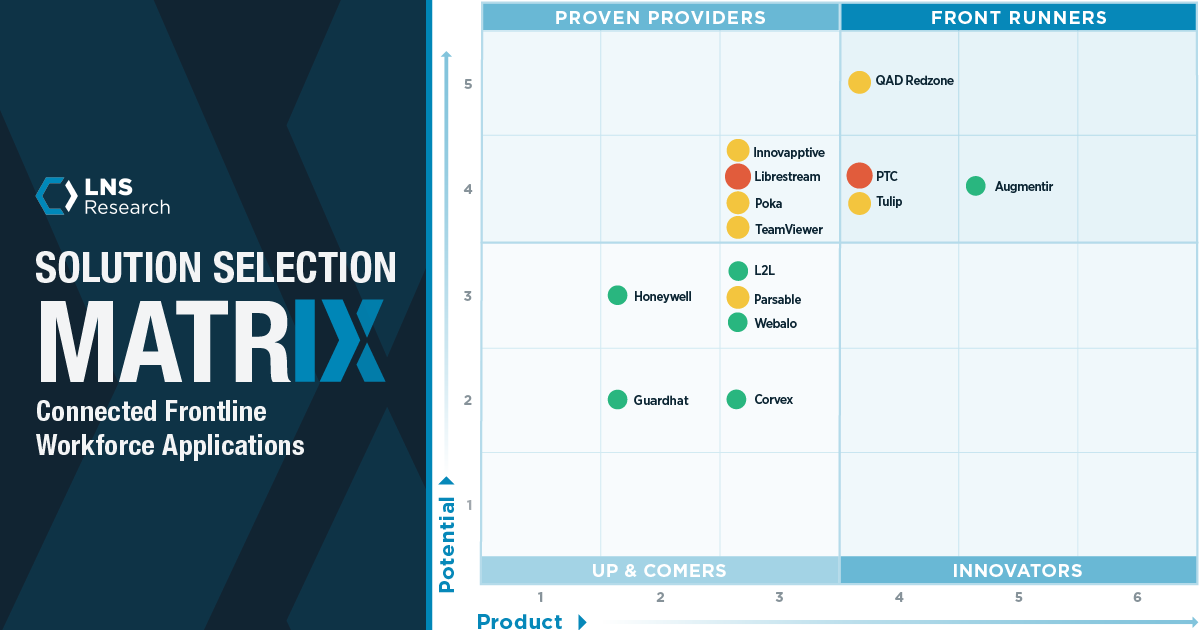

Source: LNS Research

Connected worker (or connected frontline worker – CFW) technology is a crucial part of this concept – as it connects the human workforce with the digital systems and processes in the organization.

How to create a connected enterprise

The first step to creating a connected enterprise is implementing smart, connected worker solutions. AI and connected frontline worker technologies are some of the leading solutions organizations are turning to on their path toward a Connected Enterprise. Augmentir has seen manufacturers achieve significant results after successfully implementing connected frontline worker solutions in conjunction with AI-driven analytics:

- Up to a 72% reduction in training and onboarding times

- More than 20% decrease in downtime

- Nearly a 25% increase in productivity

Solutions that incorporate enhanced mobile capabilities and combine training and skills tracking with connected worker technology and on-the-job digital guidance can deliver significant additional value for an organization’s connected enterprise initiative. Data from actual work performance combined with AI-based analytics can inform workforce development investments, and deliver smart insights that reduce time to productivity, enable targeted reskilling and upskilling, and provide individualized guidance and support at the point of work so that you get the best each person has to offer.

However, companies need to be strategic and take a structured approach. It is imperative that the right solutions are identified and tested by the right divisions, personnel, and business units.

LNS Research has developed an “Industrial Transformation Reference Architecture” approach that provides a framework and simplifies implementation into four layers:

- Business Processes and Systems

- Connected Assets and Operations

- Data and Analytics

- Connected Worker

These guidelines give organizations reference points to help guide them along their path of industrial transformation and set them up for success in connecting their operations.

Key benefits of connecting your workforce to your enterprise

By leveraging AI and other smart technologies, companies are providing workers with real-time guidance and assistance, enabling them to perform their jobs more effectively. Frontline workers can access information, collaborate with colleagues, and receive real-time alerts on potential hazards, all of which help to improve their productivity and safety.

The benefits offered by AI and connected technologies are significant:

- Improved efficiency: By automating routine tasks and providing real-time information, AI and connected worker technologies can help streamline operations and reduce errors.

- Increased productivity: AI and connected worker technologies can help workers perform their jobs more effectively, enabling them to produce more goods in less time.

- Better quality control: By providing real-time data on production processes and product quality, AI and connected worker technologies can help identify issues early and prevent defects.

- Enhanced safety: Connected worker technologies can provide workers with real-time guidance and assistance, enabling them to perform their jobs more safely and avoid accidents.

- Cost savings: By reducing downtime, improving efficiency, and enhancing product quality, connected worker technologies can help companies save money and increase profitability.

- Improved decision-making: By providing real-time insights and data analytics, connected worker technologies can help companies make more informed decisions about their operations and identify new opportunities for growth.

According to McKinsey & Company, by 2030, the adoption of “Connected Enterprise” technologies is expected to generate $1-2 trillion in value for the global economy, including the manufacturing industry. As the transformation from paper processes to digital continues, industrial organizations are consistently finding that CFW solutions are an essential component of a larger “Connected Enterprise”. By leveraging AI and other advanced technologies to better analyze data and provide actionable insights, companies empower workers with the tools to perform their jobs more effectively, improving productivity, efficiency, and safety. Adopting AI and connected worker technologies is a key part of industrial transformation and of “Connected Enterprise” initiatives, offering industrial organizations an enhanced competitive advantage and solutions to many of the obstacles they face in today’s markets.

Implementing a connected enterprise with Augmentir

If you are interested in learning for yourself why companies are choosing Augmentir to help them connect, digitize, and optimize their frontline operations – reach out to book a demo.