AI is playing a key role in changing the manufacturing landscape, augmenting workers and empowering them with improved, optimized processes, better data, and personalized instruction.

Deloitte recently published an article with the Wall Street Journal covering how AI is revolutionizing how humans work and its transformative impact. They emphasized that AI is not merely a resource or tool, but, that it serves almost as a co-worker, enhancing work processes and efficiency. This article discussed how the evolving form of intelligence augments human thinking and emphasized this as a catalyst for accelerated innovation.

Manufacturing is uniquely situated to benefit from AI to improve operations and empower their frontline workforces. The skilled labor gap has reached critical levels, and the market is under tremendous stress to keep up with growing consumer demand while staying compliant with quality and safety standards. Manufacturing workers are crucial to the success of operations – maintenance, quality control and assurance, and more – manufacturers rely upon their workforce to ensure production proceeds smoothly and successfully.

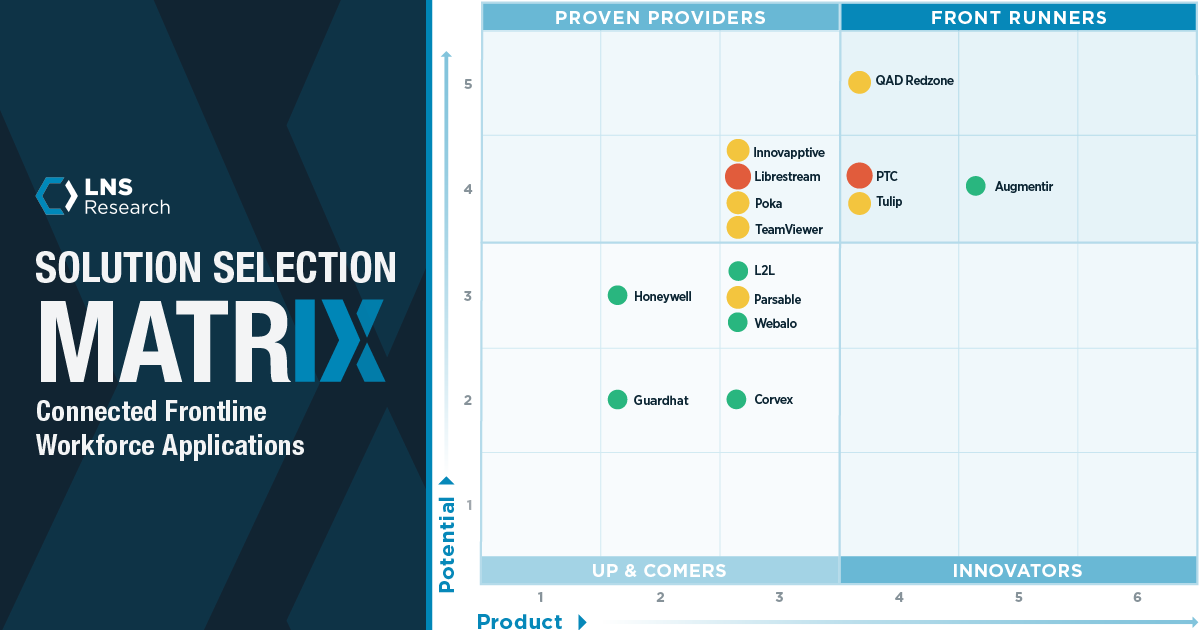

AI is playing a key role in changing the manufacturing landscape, augmenting workers and empowering them with improved, optimized processes, better data for informed decision-making, troubleshooting, personalized instructions and training, and improved quality assurance and control. According to the World Economic Forum, an estimated 87% of manufacturing companies have accelerated their digitalization over the past year, the IDC states 40% of digital transformations will be supported by AI, and a recent study from LNS Research found that 52% of industrial transformation (IX) leaders are deploying connected worker applications to help their frontline workforces. Not only that, AI technology is expected to create nearly 12 million more jobs in the manufacturing industry.

Integrating AI into manufacturing not only enhances productivity, but also opens the door to new possibilities for worker safety, training, and innovative new manufacturing practices. Here are some ways AI is transforming manufacturing operations:

- AI-based Workforce Analytics: Collecting, analyzing, and using frontline worker data to assess individual and team performance, optimize upskilling and reskilling opportunities, increase engagement, reduce burnout, and boost productivity.

- Personalized Training in the Flow of Work: With AI and connected worker solutions, manufacturers can identify and supply training at the time of need that is personalized to each individual and the task at hand.

- Personalized Work Instructions: AI enables manufacturers to offer customized digital work instructions mapped to their skill levels and intelligently assign work based on each individual’s capabilities.

- Digital Performance Support and Troubleshooting Guide: Generative AI assistants and bot-based AI virtual assistants offer support and guidance to manufacturing operators, enabling access to collaborative technologies and knowledge bases to ensure the correct actions and processes are taken.

- Optimize Maintenance Programs: AI algorithms analyze data from sensors on machinery and other connected solutions to predict when equipment is likely to fail. This enables proactive maintenance, minimizing downtime and reducing maintenance costs. Additionally, with AI technologies, manufacturers can implement autonomous maintenance processes through a combination of digital work instructions and real-time collaboration tools. This allows operators to independently complete maintenance tasks at peak performance.

- Improve Quality Control: AI-powered solutions can improve inspection accuracy and optimize quality control and assurance processes to identify defects faster. With connected worker solutions, manufacturers can effectively turn their frontline workforce into human sensors supplying quality data and enhancing assurance processes.

- Ensure Worker Safety: AI-driven safety systems coupled with connected worker technologies monitor the work environment, supplying real-time data and identifying potential hazards to ensure a safer workplace for employees.

As AI continues to advance, the manufacturing industry is poised for even greater transformation, improving both the quality of products and the working conditions for employees. AI is revolutionizing the way humans work and how the manufacturing industry approaches nearly every process across operations, augmenting work interactions, productivity, efficiency, and boosting innovation.