The shift to smart factories offers transformational benefits that go beyond just automation. Here’s a deeper look into how businesses benefit from adopting smart manufacturing systems:

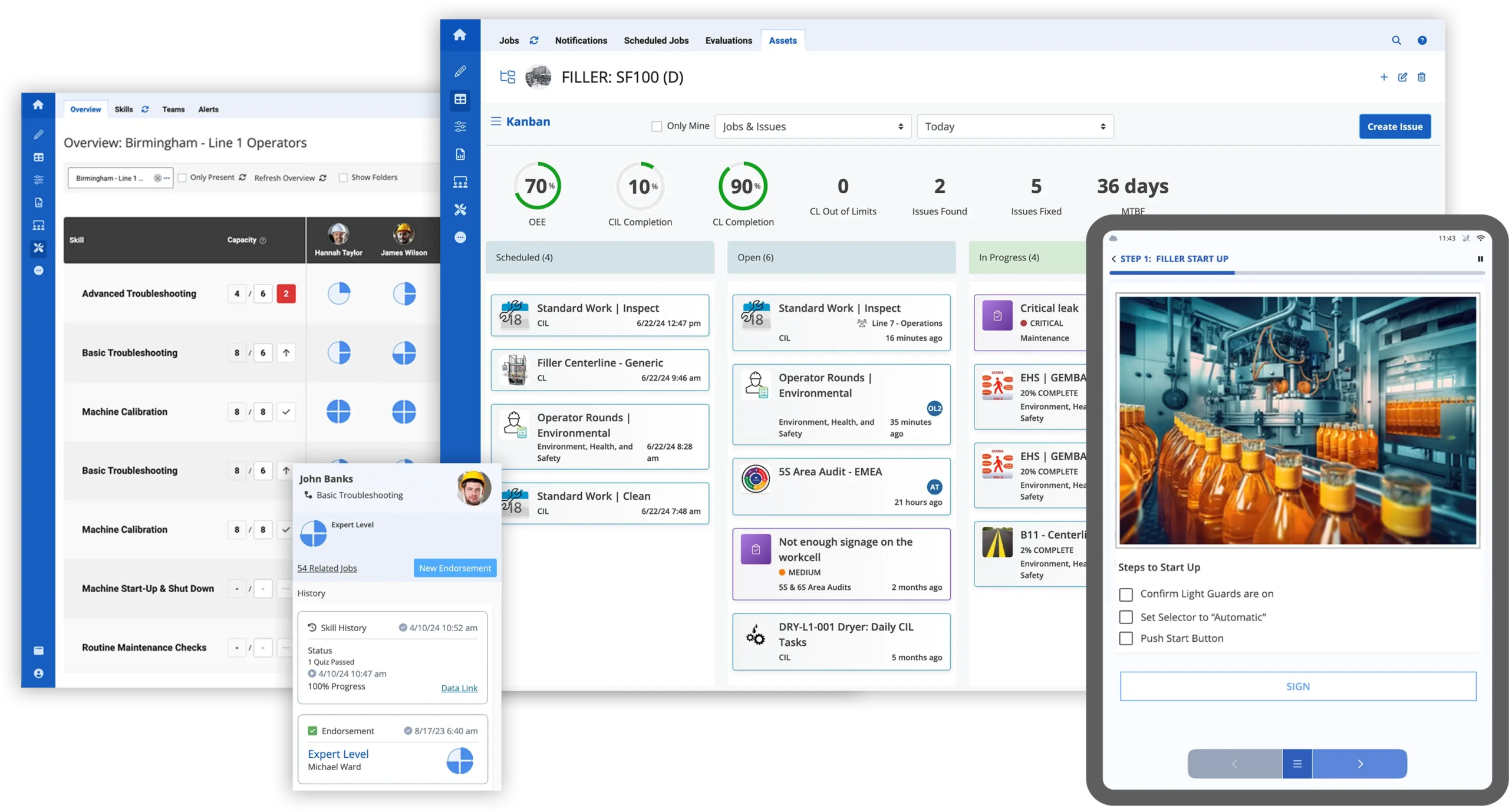

Increased Operational Efficiency

Smart factories streamline processes by using real-time data and automation to eliminate bottlenecks, reduce cycle times, and boost overall throughput. Machines can self-optimize and adapt on the fly, reducing downtime and increasing output.

Enhanced Product Quality

With continuous monitoring and AI-driven quality checks, smart factories detect defects early, reduce variability, ensure First Time Right, and maintain high-quality standards. This leads to fewer recalls, less waste, and increased customer satisfaction.

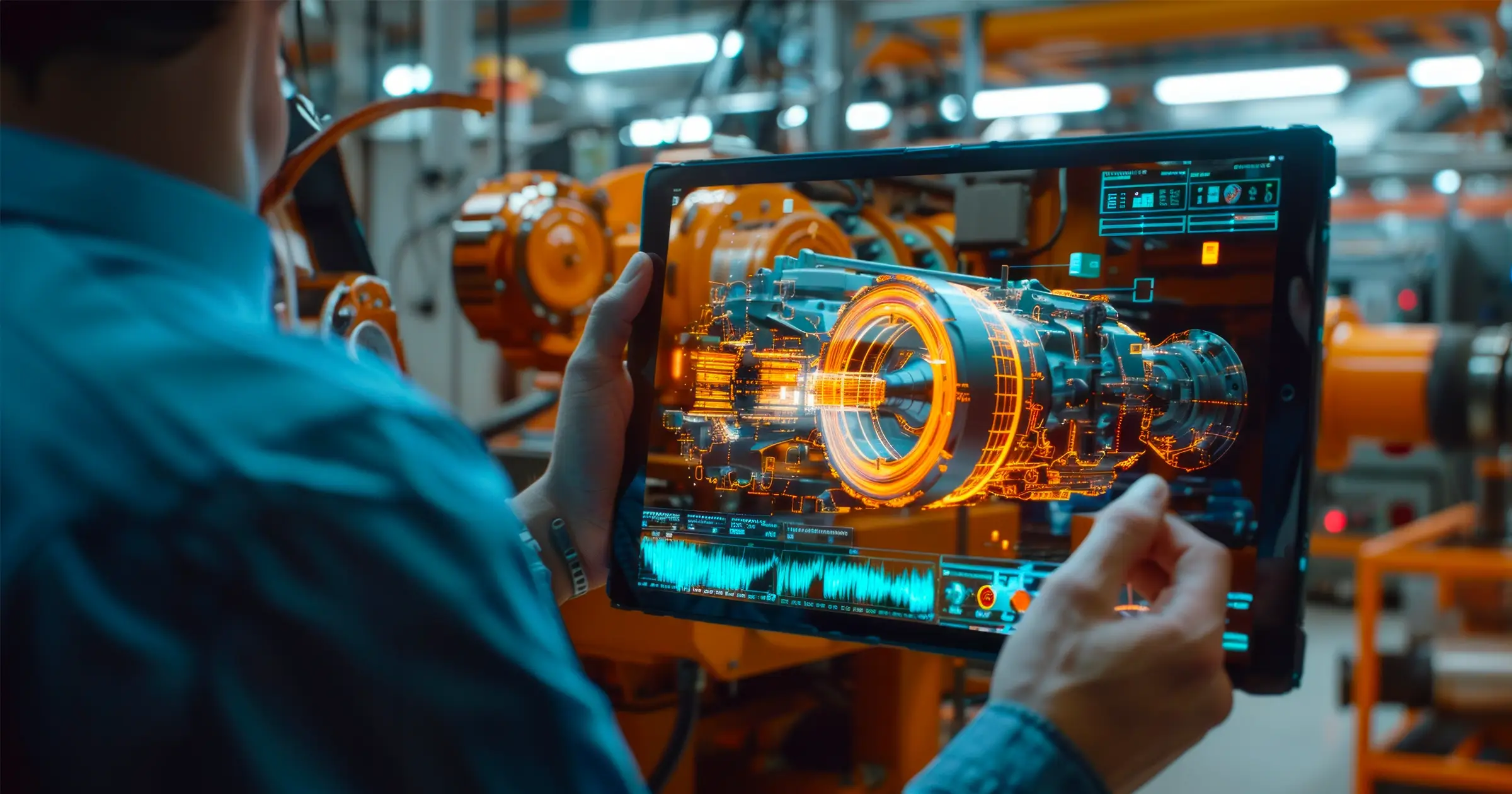

Predictive Maintenance

By using IoT sensors and machine learning, smart factories can anticipate equipment failures before they occur. This minimizes unplanned downtime, extends the life of assets, and lowers maintenance costs through proactive repairs.

Improved Supply Chain Visibility

Smart factories provide end-to-end visibility across the supply chain, allowing manufacturers to track materials, shipments, and inventory in real time. This results in better demand forecasting, faster order fulfillment, and more responsive supply chain management.

Customization and Flexibility

Modern consumers demand personalized products. Smart factories allow manufacturers to produce highly customized or small-batch orders without sacrificing efficiency, thanks to modular production lines and digital control systems.

Sustainability and Energy Efficiency

With smart energy management and resource tracking, smart factories reduce energy consumption, minimize waste, and lower their environmental impact. This supports corporate sustainability goals and reduces operational costs.

Real-Time Decision Making

The use of advanced analytics and dashboards enables decision-makers to act instantly on real-time data—whether it’s rerouting a production task, reallocating resources, or adjusting workflows on demand.

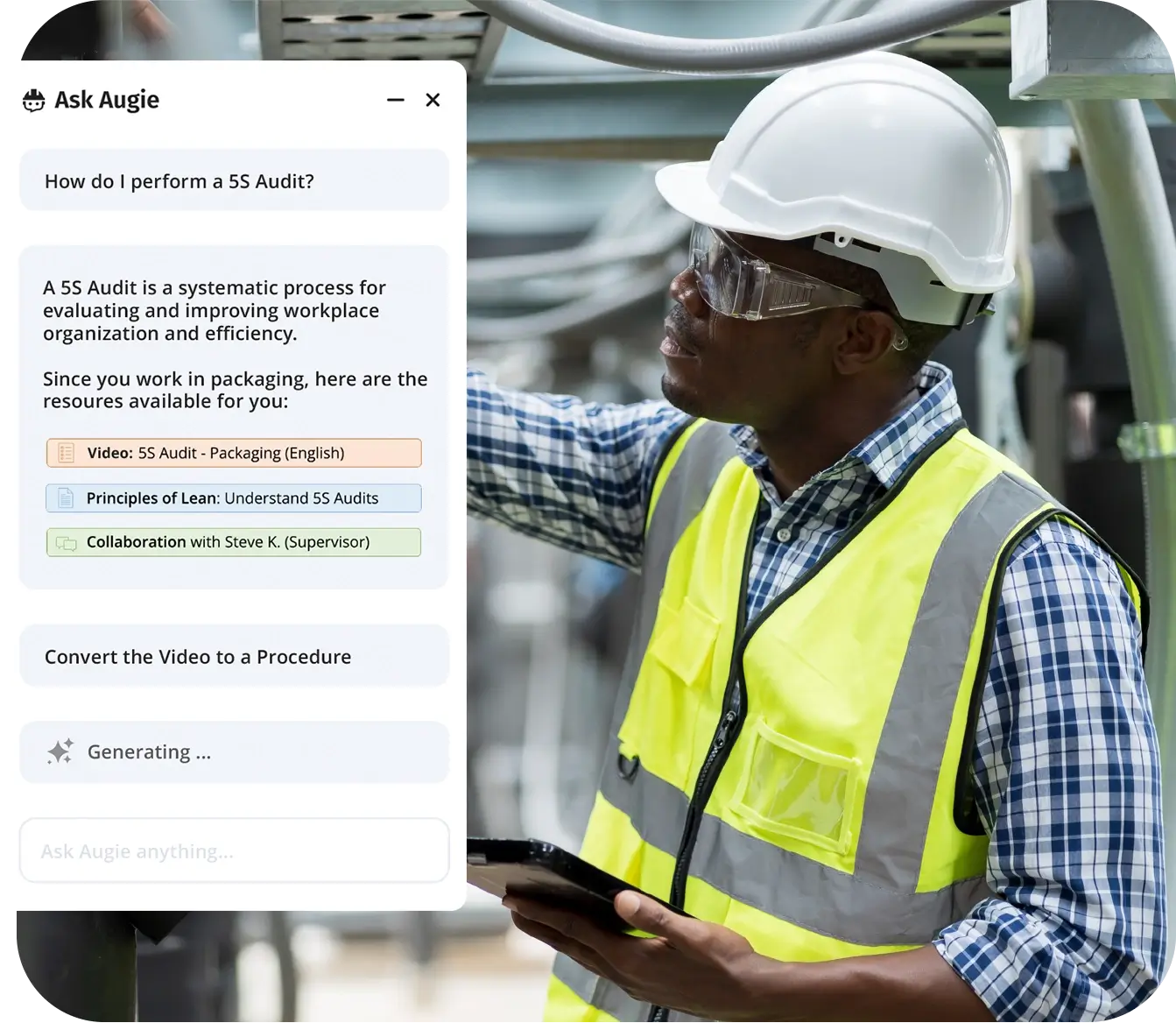

Workforce Empowerment

Connected worker technologies—such as wearables, AR, and mobile devices—equip employees with the tools they need to work smarter, not harder. It improves safety, reduces errors, and enhances productivity by guiding workers with real-time instructions and alerts.

Cost Savings Over Time

Although the initial investment in smart technology may be high, the long-term savings are substantial. Reduced waste, lower energy use, fewer breakdowns, and more efficient labor all contribute to significant cost reductions.

Competitive Advantage

Adopting smart factory principles puts manufacturers ahead of the curve. Companies that leverage smart technologies can bring products to market faster, respond to customer demands quickly, and innovate continuously—ensuring a strong position in a fast-paced global market.