What are Lockout Tagout (LOTO) Procedures in Manufacturing?

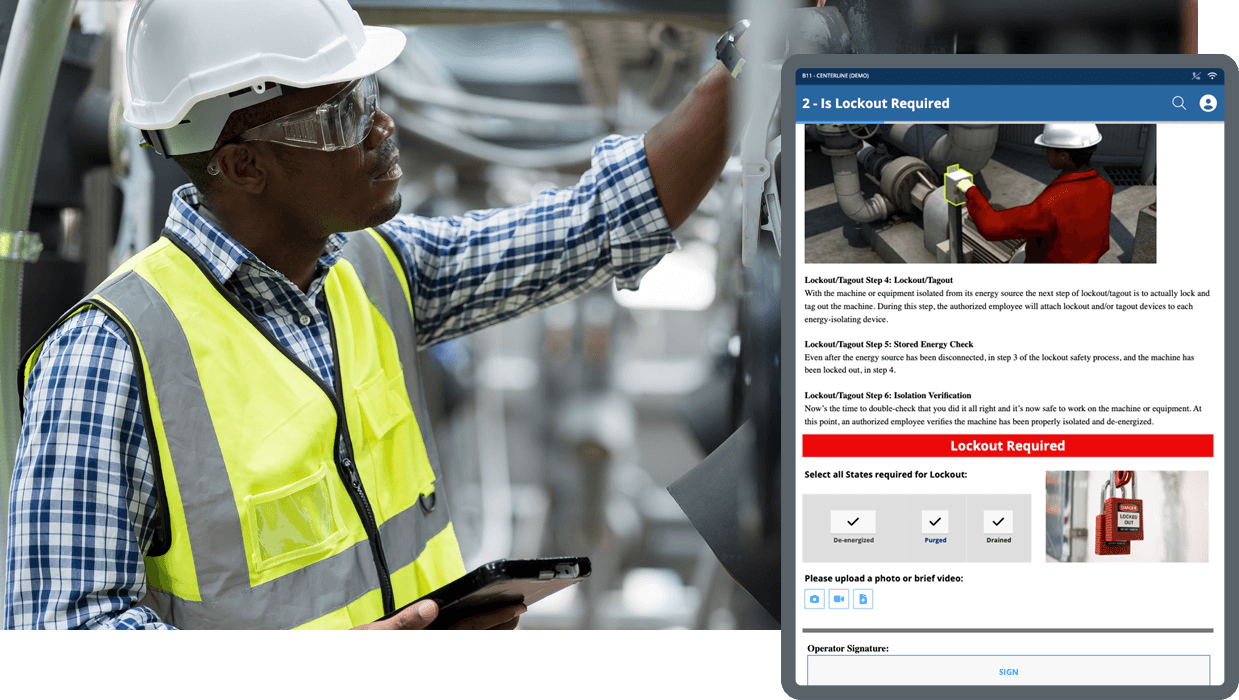

Manufacturing environments are filled with machinery and equipment that, if not properly controlled during maintenance, can lead to unexpected startups, electrocution, burns, crushing incidents, and more. Lockout Tagout (LOTO) procedures require proper training for authorized employees, including identifying energy sources, control methods, and application of lockout/tagout devices. These procedures not only prevent immediate accidents but also extend the overall life of machines and equipment.

However, LOTO violations consistently rank among the top ten most frequently cited OSHA violations costing an average of $19,000 in fines per citation. Additionally, it’s estimated that LOTO compliance could help prevent approximately 120 fatalities and 50,000 injuries every year. Learn more about LOTO processes below, and how they keep manufacturing operations and frontline workers safe: