The overarching objective of digitization is to increase operational real-time visibility and make it easier for workers to do their jobs efficiently and correctly. To accomplish that, you must digitize your manufacturing processes.

First, you’ll want to look at your current paper-based reporting methods to see what can be streamlined and automated. Paper forms offer room for waste, product defects, and regulatory compliance issues.

Consider digitizing everyday processes like standard operating procedures (SOPs), work instructions, and other paper documents. This can be done by implementing connected worker software to digitize production processes.

Digitization works hand in hand with digitalization, the practice of using technologies to automate paper-based processes. Some of these smart devices like IoT sensors provide better insights to management when it is integrated into your digitized procedures.

Some of those technologies may include implementing:

- Industrial IoT sensors to measure and monitor manufacturing processes

- Machine health monitoring sensors to assess machine performance

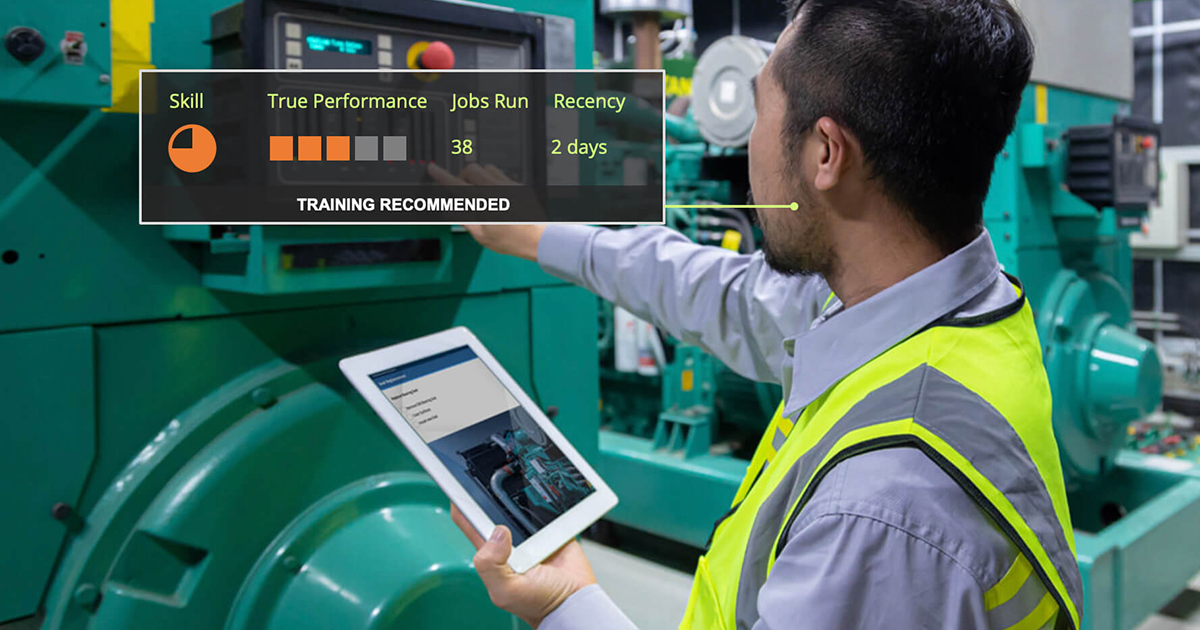

- AI and Machine learning to improve workforce efficiency

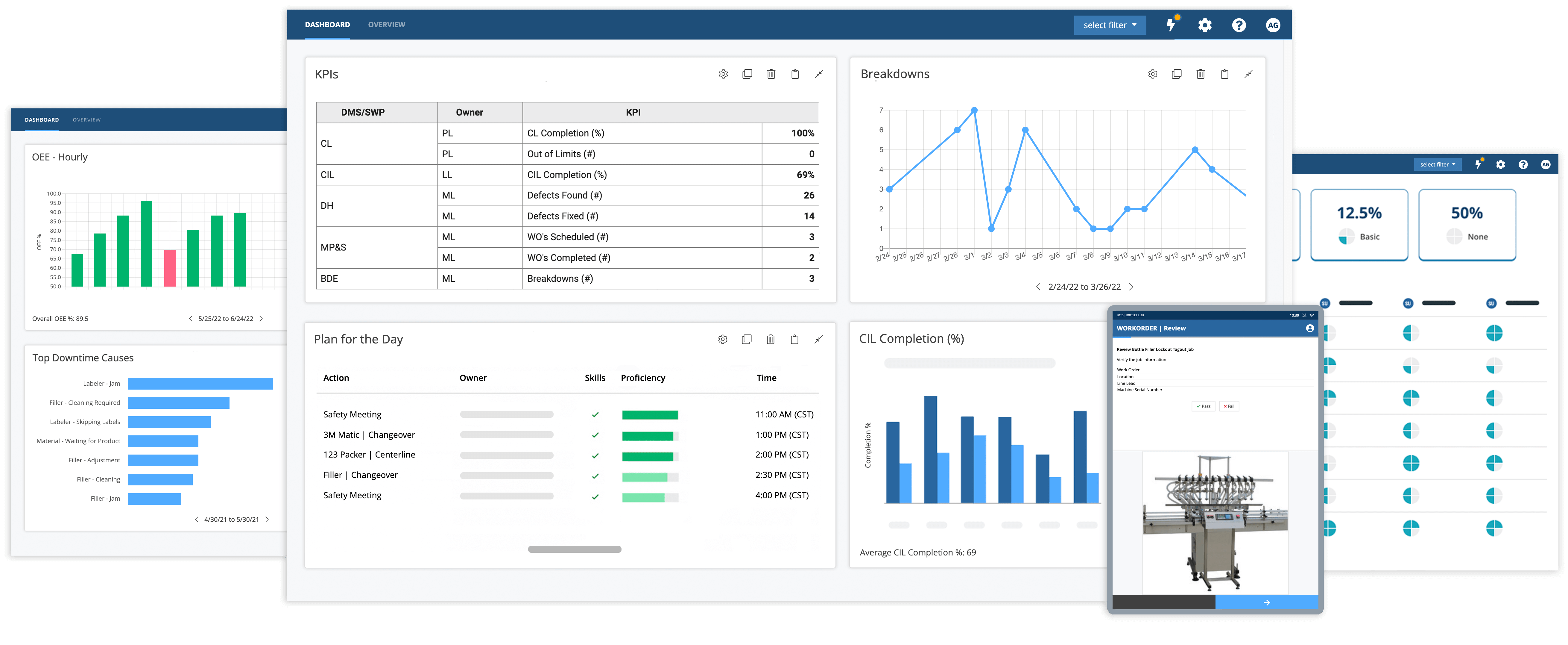

We recommend connecting all of your technologies to a central cloud-based platform and creating customized dashboards best suited to your company’s goals. A connected worker solution provides greater worker and equipment visibility.

Lastly, getting managers and leadership involved early in digitizing manufacturing processes will ensure that it’s here to stay for the long haul. Digitization enables everyone to be on board, from shop floor workers to the head of the company. All employees must be on the same page regarding what to digitize and the best approach for doing so.