It’s crucial to know where your product flaws are stemming from. Only then can you correct procedures that may be adding to those problems. Check out the following tips to get a better idea of how to improve FTQ in your everyday operations.

Step 1: Inspect materials

The quality of your materials has a huge impact on the goods you produce. It’s important to inspect materials to make sure that you and your suppliers are on the same page when it comes to quality standards.

A supplier may sometimes distribute supplies that have defects from the get-go. Failure to remove defective materials can lead to faulty products down the line.

Step 2: Practice machine and equipment upkeep

Once you’ve ruled out that your materials are not the issue, it’s vital to review your machinery for potential malfunctions. Over time, even the most advanced equipment can break down.

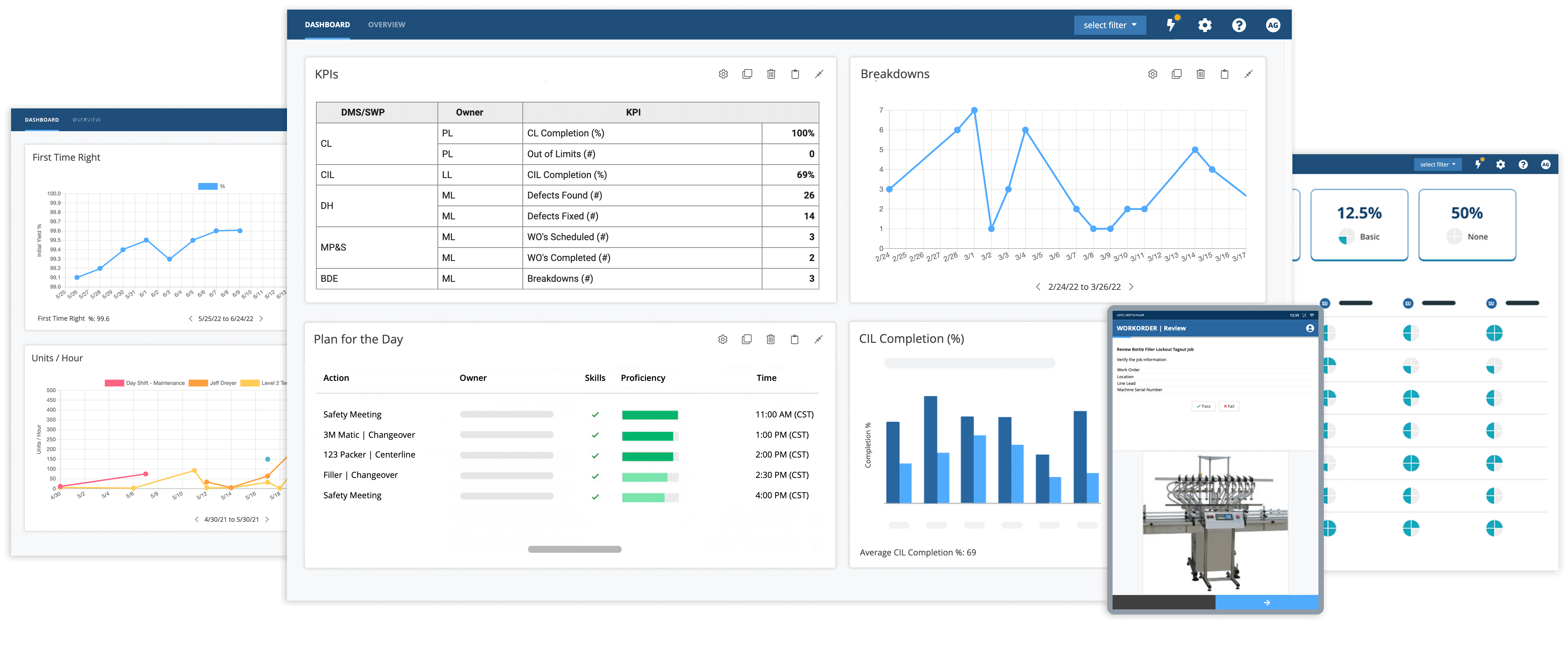

Regular machine inspection and repair is necessary to ensure that your equipment is not the reason for product defects. Routine maintenance can also prevent workers from having to stop a production process because they are waiting for equipment to be fixed. If the issue is resolved before a worker begins a process, it reduces the chances of having to stop operations.

Step 3: Implement process documentation

Proper documentation of procedures and the steps involved in carrying out each one can decrease the chances of imperfect goods. This is imperative for first time quality, especially if there’s changeover in a company. The better your written procedures are, the more likely that workers will perform tasks right the first time around. Quality control checklists are a great way to standardize your quality process documentation and ensure your first time quality targets are met.

Quality Control Checklist

Free Template

Standardize and optimize QA for reduced defects and rework with our free Quality Control Checklist Template. Download our PDF template to get started, and learn more about digitizing your quality data collection and inspection procedures with Augmentir.

Up-to-date instructions ensure that everyone knows how to execute duties in the right order and in the right way, enabling them to produce the same outcome each time. This can help eliminate any defects from human error.

Augmentir offers solutions to increase first time quality for all your frontline operations. Our connected worker solution will help you digitize and transform how you write and implement production procedures to eliminate inconsistencies. Learn more about our quality use cases.